DLPU137 April 2024

- 1

- Description

- Features

- Applications

- 5

- 1Evaluation Module Overview

- 2Hardware

- 3Software

- 4Hardware Design Files

- 5Additional Information

2.4 RGB LED Driver PCB - DLP4620SQ1

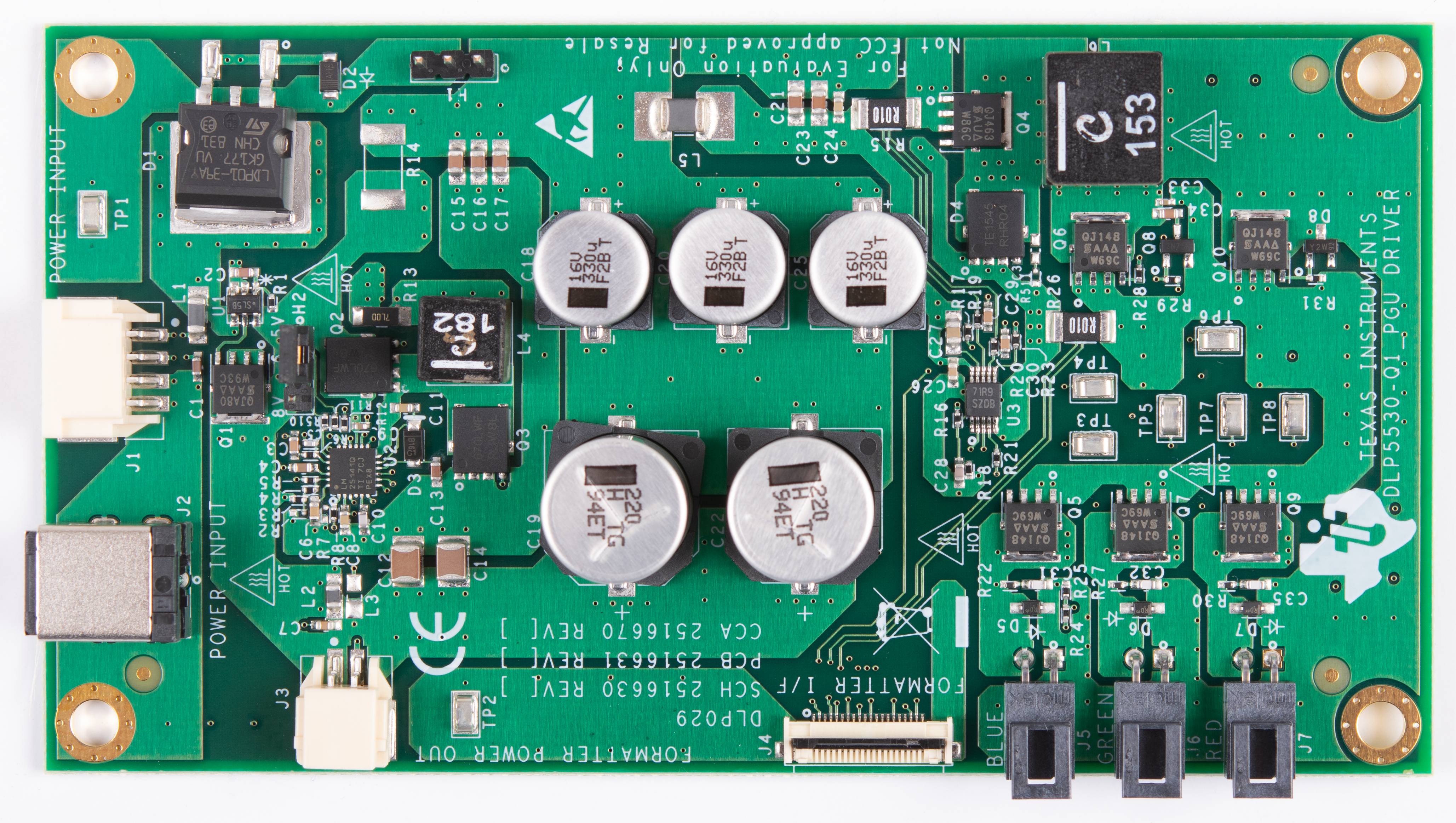

The DLP4620SQ1EVM can operate as a standalone system with just the controller board and the DMD board, but the EVM can be combined with an RGB LED design. The LED driver board shown in Figure 3-6 is controlled and monitored by the controller PCB over a flex cable. Power can be input to the LED driver board from a bench top supply or through a 12V, 5A barrel jack power supply. Depending on operating conditions, some parts and surfaces of the PCB can be hot.

The LED driver board has the following primary functions:

- Provides reverse bias protection and supplies power to controller board over a separate cable.

- Regulates input power to 6.5V or 8V prior to the LED driver circuitry.

- Has outputs for red, green, and blue LEDs, but other LEDs can be used.

The LED driver board can reach temperatures above 55°C without proper cooling and airflow. Contact can cause burns! |

LED drivers (J5, J6, J7) can produce high currents of 6.5A or 8A. Do not remove these headers, and do not touch the contact points during operation! |

Figure 2-4 LED Driver PCB - DLP4620SQ1EVM

Figure 2-4 LED Driver PCB - DLP4620SQ1EVMThe LED driver PCB contains the ports listed in Table 3-7.

| SCHEMATIC REFERENCE | FUNCTION |

|---|---|

| J1 | Input power |

| J2 | Input power (optional) |

| J3 | Controller power |

| J4 | Controller-driver control interface |

| J5 | Blue LED output - high current output up to 6A, locking and keyed connector |

| J6 | Green LED output - high current output up to 6A, locking and keyed connector |

| J7 | Red LED output - high current output up to 6A, locking and keyed connector |

The LED driver PCB contains the headers listed in Table 3-8. H2 selects the LED drive voltage. Place a jumper across pins 1 and 2 for 6.5V drive. Place a jumper across pins 2 and 3 for 8V drive. Do not hot-swap this jumper; remove and replace only with power disconnected from the board.

| HEADER | PIN1 | PIN2 | PIN3 |

|---|---|---|---|

| H1 | Pre-regulated drive voltage

(6.5V or 8V) |

GND | GND |

| H2 | Feedback voltage connection

for 6.5V drive |

Pre-regulator feedback voltage | Feedback

voltage connection for 8V drive |