SCEA124 june 2023 LSF0101 , SN74LXC2T45 , TXU0104 , TXU0204 , TXU0304

Solar energy represents a renewable energy source that can help companies and individuals reduce their reliance on hydrocarbon-based energy sources. However, for solar energy to become a reliable source of energy it needs to be stored in an efficient manner. Battery energy storage systems (ESS) are used to store energy generated by solar panel installations. Battery energy storage systems need to coordinate their operation with other solar energy system components such as smart meters and solar panel inverters. Although battery energy storage system technology has been available for quite some time, for individuals and companies to take advantage of it at a large scale, electrical grids around the world need to become smarter and more efficient. Smart battery storage technologies are enabling capabilities essential to successful solar implementations such as 24/7 solar energy usage and reduced down times. In addition, smart battery storage systems are enabling utility companies to offer unique services and promotions to help incentivize companies and individuals to invest in solar power generation and storage equipment and adopt energy savings usage activities. Smart energy storage systems can incorporate many different capabilities but their ability to wirelessly send and receive information is arguably the most important. Wireless connectivity enables energy storage systems, to not only send available energy data to the system users as well as to the utility company, but it also enables the energy storage systems and smart meters to respond to commands from the utility company turning a group of individual battery storage systems to an array of energy storage that utility companies can tap into during times of peak demand.

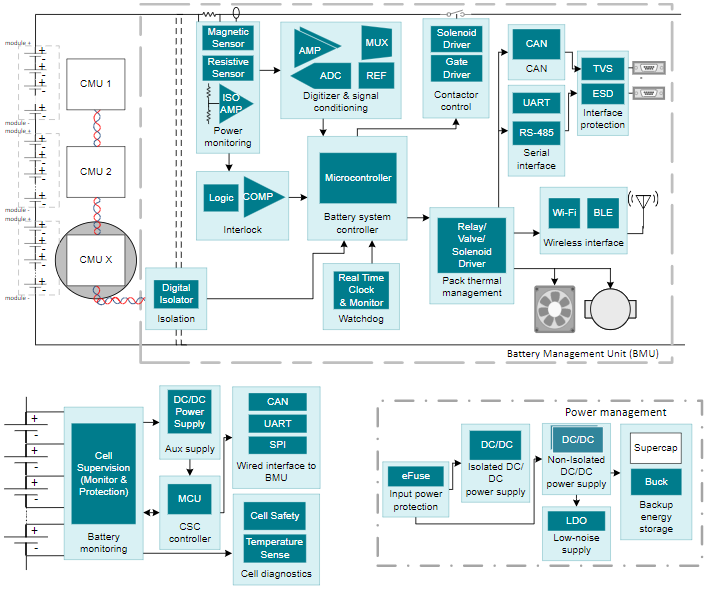

Given the importance of connectivity within smart battery energy system designs, the implementation of the wireless connectivity function within a smart ESS is often a key concern for system designers. Today, many smart ESS designs use special communications modules that are designed for specific communications standards, such as 3G, 4G-LTE, 5G, LPWA as well as shorter range standards such as Zigbee, Wireless M-Bus, Wi-Fi and Bluetooth. An example of a modern smart ESS is shown in Figure 1. One challenge that designers face when incorporating communications modules into their design is interfacing the module with the ESS's existing processor control and data I/O (input/output). Often, the components that are incorporated into the module are designed in different silicon process technologies that drive the need for the modules to operate on voltage nodes that are different than common voltage nodes used by mainstream microcontrollers and processors.

Figure 1 Reference Diagram for Smart Battery Energy Storage System

Figure 1 Reference Diagram for Smart Battery Energy Storage SystemTo overcome the challenges posed by I/O voltage level mismatch between an ESS's main processor and the communications module, ESS designers can use simple building block devices like voltage level translators. Voltage level translators enable designers to quickly and cost effectively level shift the control and data interfaces between the module and processor allowing the two devices to interoperate. Level translators are available in a wide variety of configurations covering channel counts from 1 to 32 channels with support for voltage levels from 0.65 V to 5.5 V. Level translator devices can be used to level shift common interface standards such as SPI, I2C, UART as well as GPIO for more custom interface implementations. TI’s level translation landing page is a great resource for finding level translators for a smart ESS design. Let’s take a look at a few examples of level shifting for some of these common interface types.

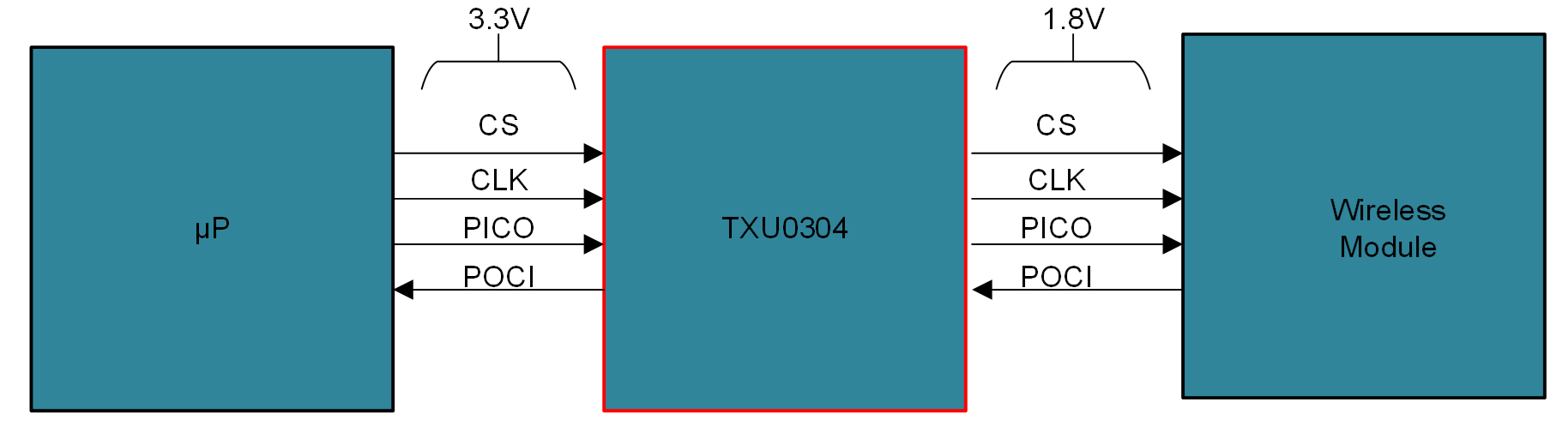

If the interface between a communications module and the ESS's processor is SPI (Serial Peripheral Interface), then a device like TXU0304 can provide an efficient and easy way to implement a level translation solution as shown in Figure 2. The TXU0304's fixed direction configuration makes it ideal for SPI where not all the channels of the interface are operating in the same direction.

Figure 2 SPI Level Translation Example using TXU0304

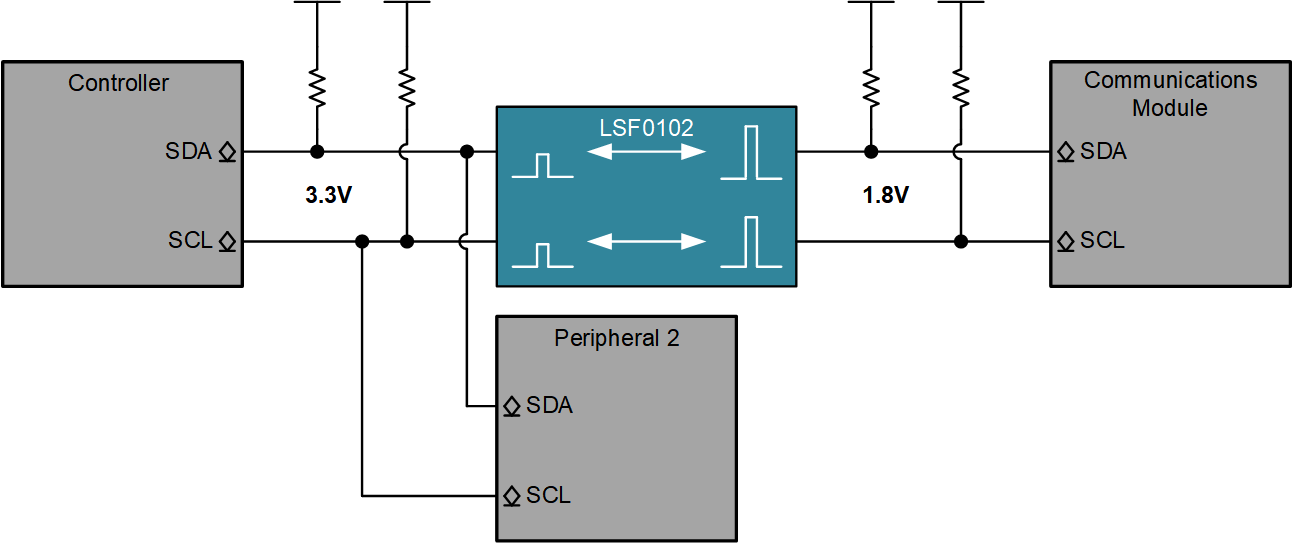

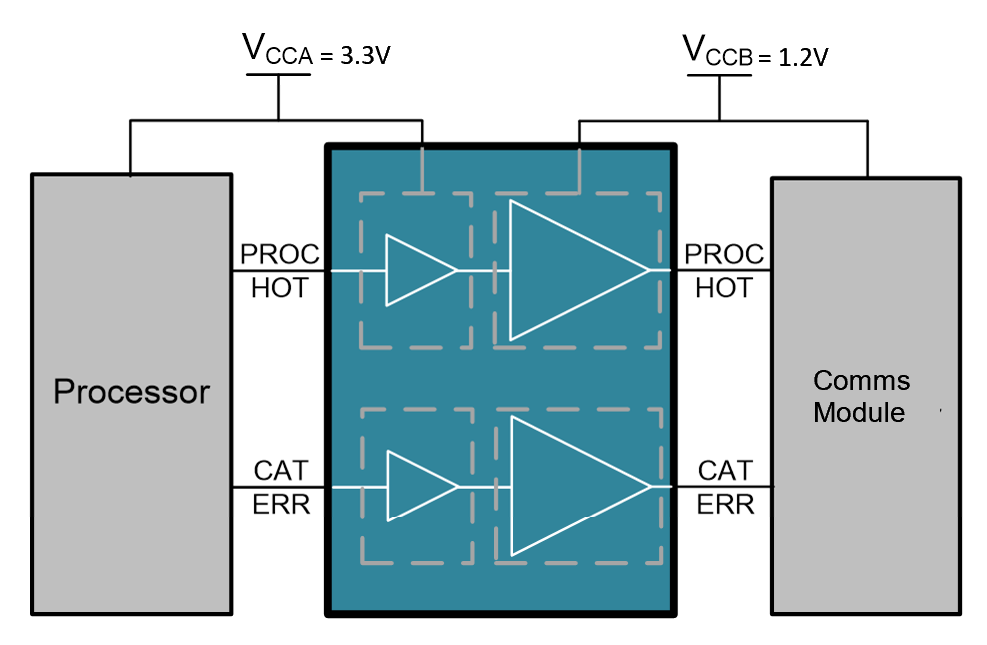

Figure 2 SPI Level Translation Example using TXU0304Another common control interface between a communication module and an ESS's microcontroller is I2C. I2C control buses are very common open-drain control buses implemented in many systems. Often, the controller will be operating on a common voltage node such as 3.3V with 3.3 V I2C control bus while the communications module will be operating at a lower voltage such as 1.8 V with 1.8 V or lower voltage I/O. In this case, an auto directional level translator such as LSF0102 can be used to level shift between the 1.8 V I2C I/O of the communications module and the 3.3 V I2C control bus as shown in Figure 3. Similarly, General Purpose I/O (GPIO) can be level shifted as shown in Figure 4. As smart ESS technology evolves, level translation solutions from Texas Instruments can enable smart ESS designers to implement critical connectivity between sub-systems within their designs. For more information on level translation and smart grid solutions visit TI’s level translation landing page as well as the grid infrastructure solutions page on TI.com.

Figure 3 I2C Bus Level Translation Example using LSF0102

Figure 3 I2C Bus Level Translation Example using LSF0102 Figure 4 GPIO Level Translation Example using SN74LXC2T45

Figure 4 GPIO Level Translation Example using SN74LXC2T45