SLAAE63 August 2022 MSP430FR2353 , MSP430FR2353 , MSP430FR2355 , MSP430FR2355

1 Introduction

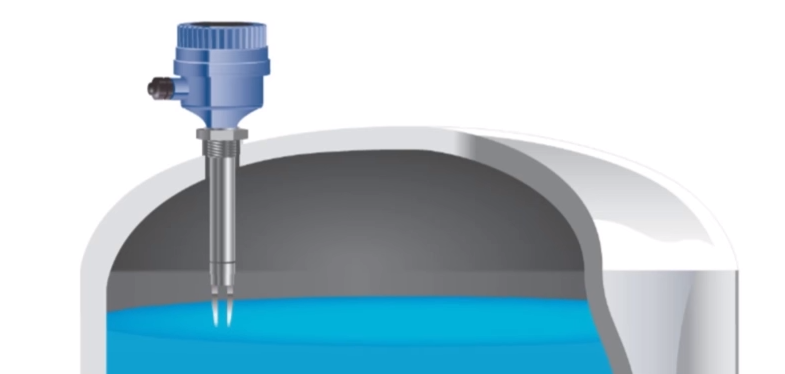

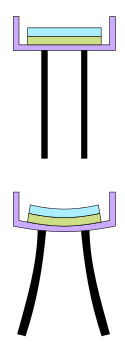

Tuning fork level switch sensors are used for monitoring viscous liquid levels in industrial applications to detect levels of liquid, grain, or powder-like material in a storage tank as shown in Figure 1-1. The physics behind this method is that a piezoelectric crystal oscillates a tuning fork at its natural frequency, as shown in Figure 1-2. The frequency and amplitude of the sensor depends on the medium in which the tuning fork is immersed. If the fork is immersed in material (tank filled up to point where sensor is installed) the resonance frequency and amplitude change correspondingly.

Figure 1-1 Tuning Fork Level Industry Application Diagram

Figure 1-1 Tuning Fork Level Industry Application Diagram Figure 1-2 Physical Oscillation of Piezo-Electric Diagram

Figure 1-2 Physical Oscillation of Piezo-Electric DiagramMembers of the MSP430FR235x microcontroller (MCU) series are ultra-low power low-cost devices for sensing and measurement applications with analog integration. MSP430FR235x MCUs integrate four configurable smart analog combos (SACs) for analog signal conditioning. Each SAC features a 12-bit digital-to-analog converter (DAC) and a configurable programmable-gain amplifier (PGA) to meet the specific needs of a system while reducing the BOM and PCB size. The integrated 12-bit 200-ksps analog-to-digital converter (ADC) digitized the analog input value for further processing. Timers generate the driving signal and the ADC conversion timing. This application note implements a low cost and compact digital solution for tuning fork level switches based on the MSP430FR2355 MCU.