SLAAEF5 March 2024 MSPM0G1505 , MSPM0G1505 , MSPM0G1506 , MSPM0G1506 , MSPM0G1507 , MSPM0G1507 , MSPM0L1303 , MSPM0L1303 , MSPM0L1304 , MSPM0L1304 , MSPM0L1304-Q1 , MSPM0L1304-Q1 , MSPM0L1305 , MSPM0L1305 , MSPM0L1305-Q1 , MSPM0L1305-Q1 , MSPM0L1306 , MSPM0L1306 , MSPM0L1306-Q1 , MSPM0L1306-Q1

- 1

- Abstract

- Trademarks

- 1Introduction

- 2Algorithm Introduction

- 3Gauge GUI Introduction

- 4MSPM0 Gauge Evaluation Steps

- 5MSPM0 Gauge Solutions

- 6References

4.4.2 Communication Data Input Mode

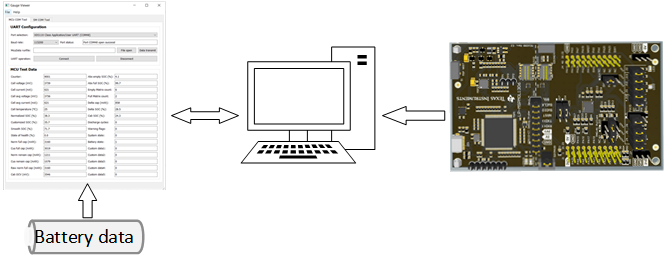

For this mode, the battery running data is input from the GUI. It enables you to run the real test case or evaluate the MSPM0 Gauge with only a LaunchPad. This method can remove the need of hardware, increase algorithm running frequency and have no limit to the length of battery running data.

Figure 4-12 Communication Data Input Mode

Structure

Figure 4-12 Communication Data Input Mode

Structure- First, to realize this method, you only need a LaunchPad and do the right hardware setting.

- Second, download the gauge code to the launchpad after changing the detection mode to "COMMUNICATION_DATA_INPUT" in "Gauge_UserConfig.h".

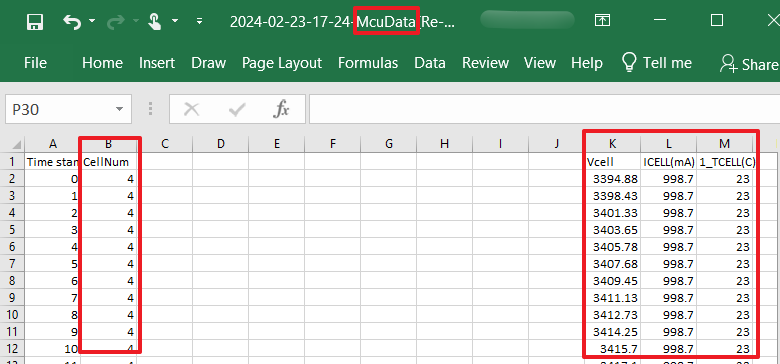

- Third, you need to have a MCUData

file. An introduction is provided on how to transmit a test data into a

recognized file by the GUI, especially for those who do not generate the test

file from GUI. You need to input the Cell num at column B. And then input every

battery's Vcell(mV), Icell(mA) and Tcell(°C) into the same column like the same

McuData file. For this, you can generate a McuData file first and refer to that

one to do the transmit ion. At last, name the file with "-McuData.xlsx".

Figure 4-13 McuData Type

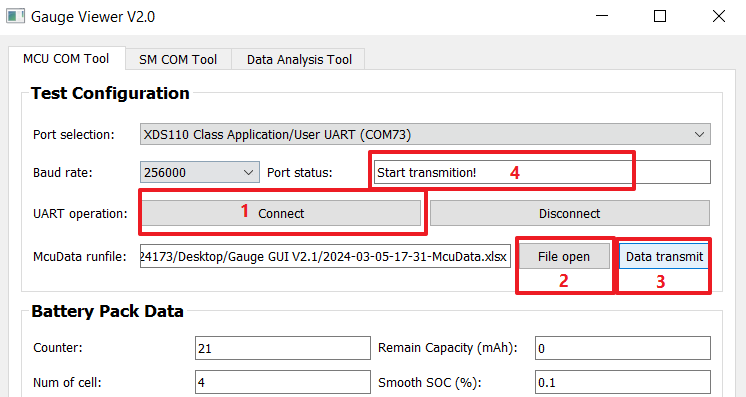

Figure 4-13 McuData Type - Forth, connect the UART COM port

following Figure 4-14 and load the MCUData runfile in MCU COM Tool by clicking the File open

button. After clicking the Data transmit button, you need to wait until the port

status changes to “Start transmit ion!”. The data load time and excel save time

will be long if the file is very large. It would be 5~10 minutes.

Figure 4-14 Communication Data

Input Steps

Figure 4-14 Communication Data

Input Steps

You will receive the battery running data from MCU shown in MCU Test Data block. After it finishes transmission, the GUI automatically saves the received data under the GUI address.