SLLA575 June 2022 DRV10987 , MCF8316A , MCT8316A

2.2.1 Auto Tuning

MCF8316A auto tunes Kp and Ki coefficients after measuring the mechanical parameters such as friction coefficient, moment of inertia through MPET.

Follow the below steps to auto tune Kp and Ki coefficients:

- Program SPD_LOOP_KP and SPD_LOOP_KI to zero.

- Enable MPET Ke measurement by setting MPET_KE to 1.

- Run the MPET by setting MPET_CMD to 1. Motor starts to spin.

- After motor stops spinning, SPD_LOOP_KP and SPD_LOOP_KI gets updated to auto tuned Kp and Ki values.

- Issue run command and track the motor speed.

- If there is any overshoot during ramp up, check the closed loop current and set the open loop current same as closed loop current.

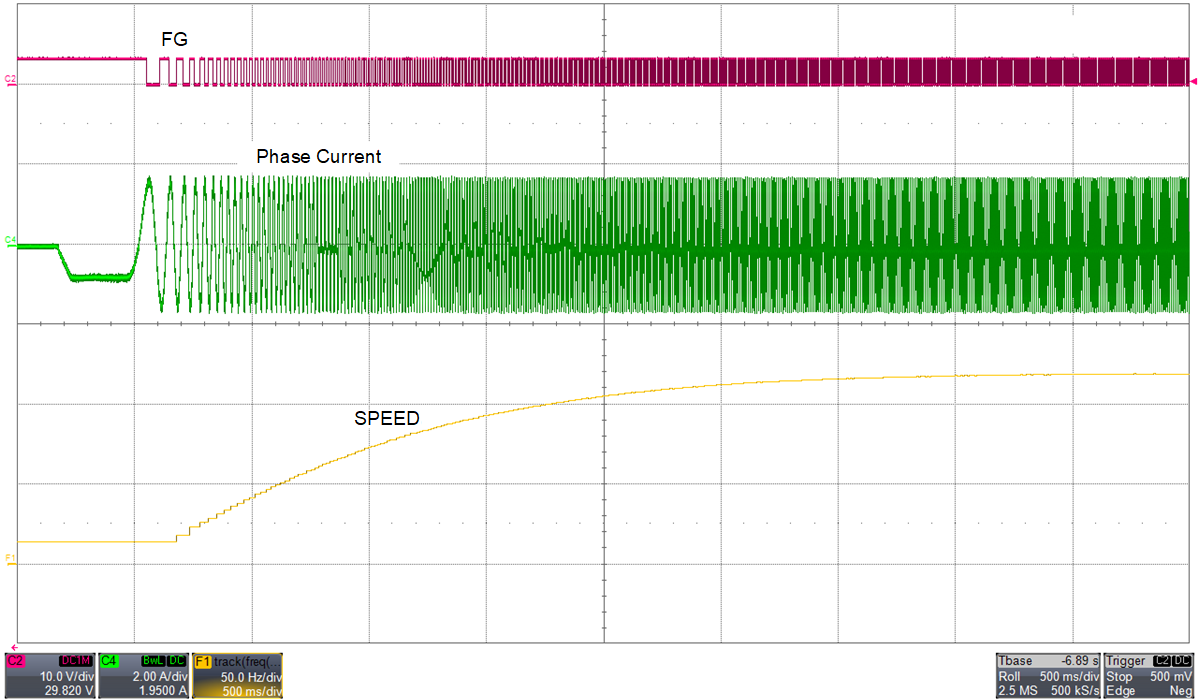

Figure 2-11 shows the FG, phase current and motor electrical speed in Hz with auto tuned Kp and Ki. Motor speed steadily ramps up to the target speed without any overshoots.

Figure 2-11 FG, Phase Current and Motor

Electrical Speed in Hz With Auto Tuned Kp and Ki

Figure 2-11 FG, Phase Current and Motor

Electrical Speed in Hz With Auto Tuned Kp and Ki