SNAA392 august 2023 LMK6C , LMK6D , LMK6H , LMK6P

BAW Resonator Technology

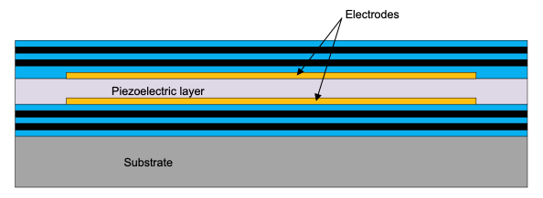

BAW is a micro-resonator technology that enables the integration of high-precision and ultra-low jitter clocks directly into packages that contain other circuits. In the BAW oscillator, the BAW is integrated with a co-located precision temperature sensor, a ultra-low jitter, low power fractional output divider (FOD), a single-ended LVCMOS and differential LVPECL, LVDS, and HCSL output driver, and a small power-reset-clock management system consisting of several low noise LDOs.Figure 1 shows the structure of the BAW resonator technology. The structure includes a thin layer of piezoelectric film sandwiched between metal films and other layers that confine the mechanical energy. The BAW utilizes this piezoelectric transduction to generate a vibration.

Figure 1 Basic Structure of a Bulk Acoustic

Wave (BAW) Resonator

Figure 1 Basic Structure of a Bulk Acoustic

Wave (BAW) ResonatorBAW Oscillator in Motor Drive Systems

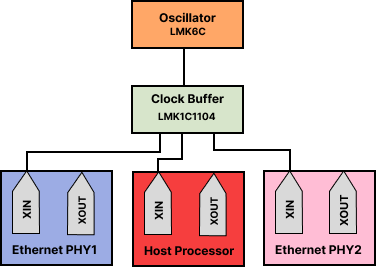

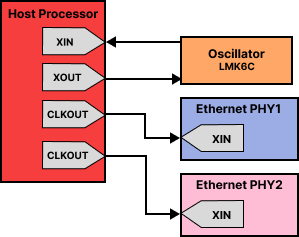

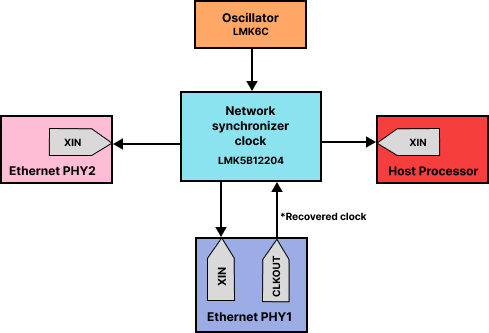

Motor drive systems are used in many industrial and manufacturing applications. The systems require precise control of position, torque, and speed for robust and reliable performance. Many applications such as AC inverter and VF drives, single and multi-axis servo drives, and stepper drives rely on EtherCAT® to transmit data to the host processor, which requires a reliable clocking architecture to achieve the best performance. Figure 2, Figure 3, and Figure 4 show common clocking architectures for standard EtherCAT applications.

Figure 2 Topology 1

Figure 2 Topology 1 Figure 3 Topology 2

Figure 3 Topology 2 Figure 4 Topology 3

Figure 4 Topology 3Benefits of the BAW Oscillator

TI's BAW oscillators have many benefits including the following:

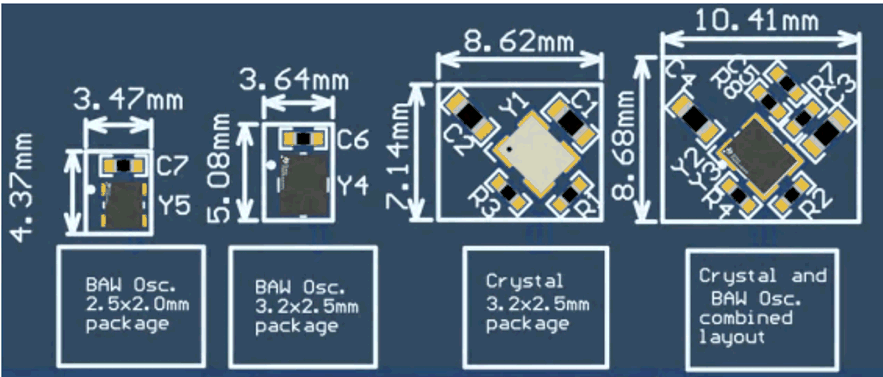

- BAW oscillators are available in small package sizes (3.2 mm × 2.5 mm and 2.5 mm × 2.0 mm) and do not require the additional capacitors that crystals require, which allows for reduced PCB space that is allocated to the oscillator. Figure 5 shows how using a BAW oscillator can help save PCB space.

Figure 5 PCB Footprint Comparison of BAW

Oscillator and Crystal

Figure 5 PCB Footprint Comparison of BAW

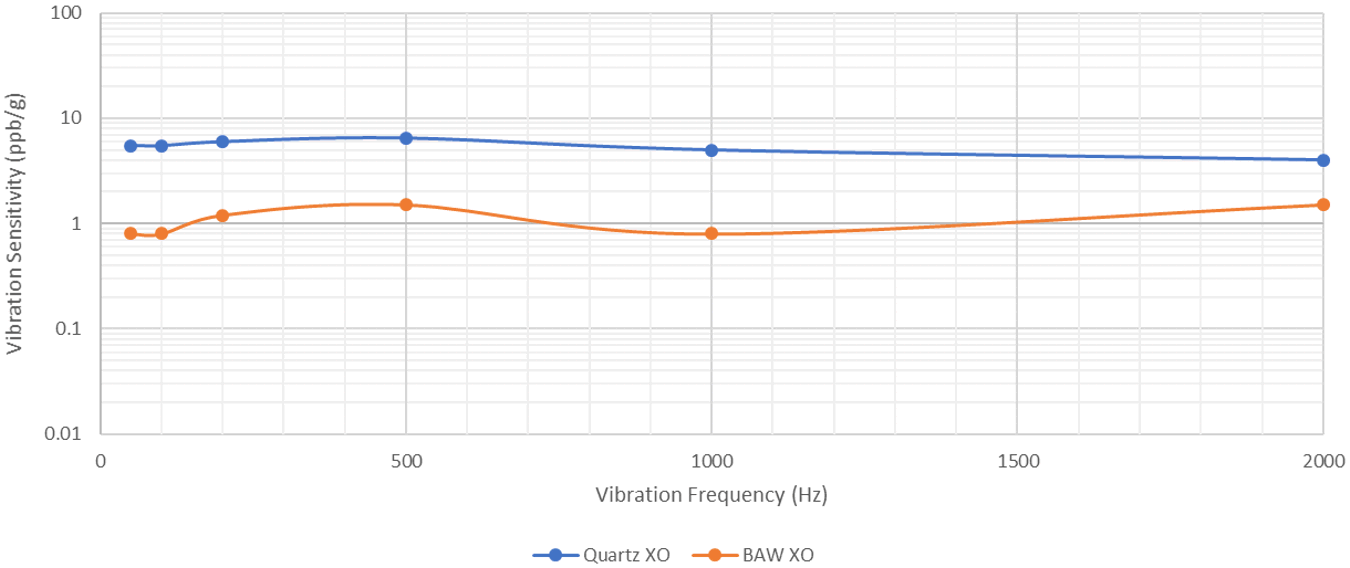

Oscillator and Crystal- BAW technology enables high resiliency to harsh environmental conditions, such as mechanical shock and vibration and achieves 100× better MTBF compared to quartz based designs. As shown in Figure 6, BAW oscillators experience only 1 ppb/g vibration sensitivity, which is 10× better than quartz-based designs.

Figure 6 BAW Oscillator Vibration

Sensitivity

Figure 6 BAW Oscillator Vibration

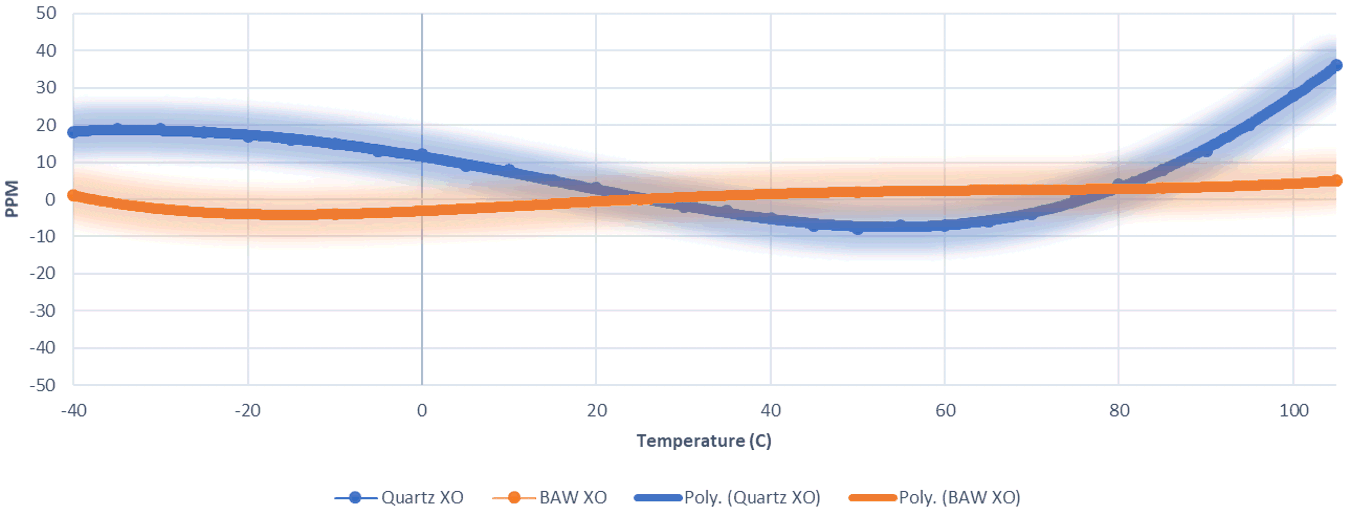

Sensitivity- BAW oscillators maintain a temperature stability of ±10 ppm over temperature from -40 to +105°C.

Figure 7 Temperature Stability Comparison of

BAW Oscillator and Quartz

Figure 7 Temperature Stability Comparison of

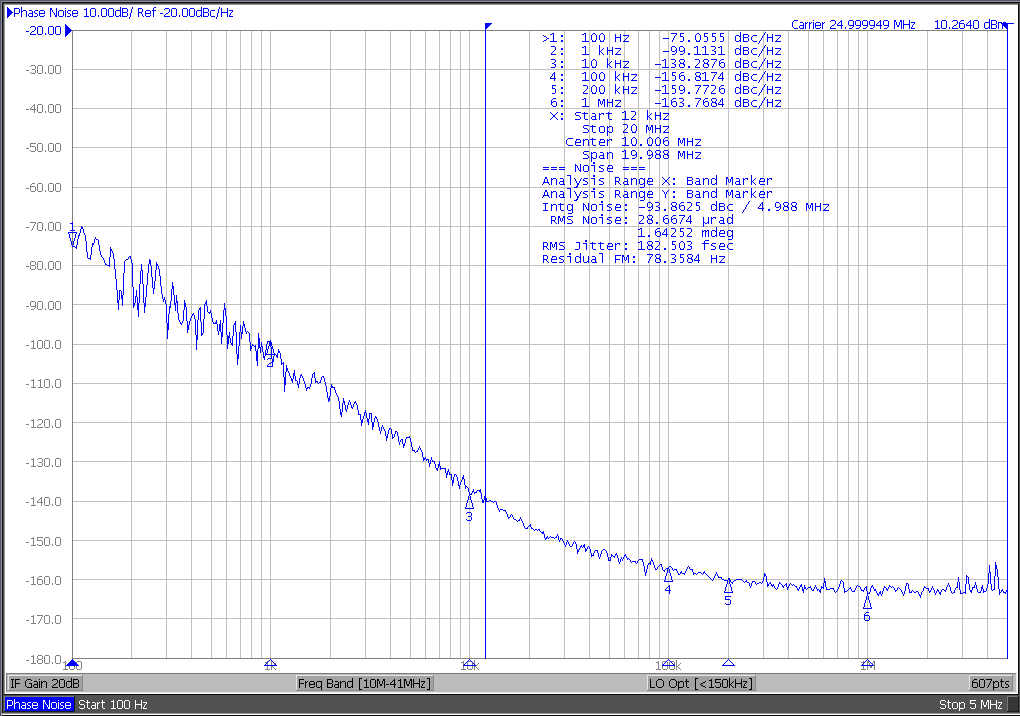

BAW Oscillator and Quartz- LMK6C oscillators support a RMS jitter of 250 fs (typical), resulting in optimized BER performance and improved synchronization between the processor and Ethernet PHY.

Figure 8 LMK6C BAW Oscillator 25-MHz Phase

Noise Performance

Figure 8 LMK6C BAW Oscillator 25-MHz Phase

Noise Performance- BAW oscillators include an integrated LDO which provides high-power supply noise immunity.

Figure 9 LMK6 BAW Simplified Block Diagram with

Integrated LDO

Figure 9 LMK6 BAW Simplified Block Diagram with

Integrated LDO