SNVAA22 June 2021 LP8867-Q1 , TMP61-Q1

3 LP886x-Q1 TSET Implementation

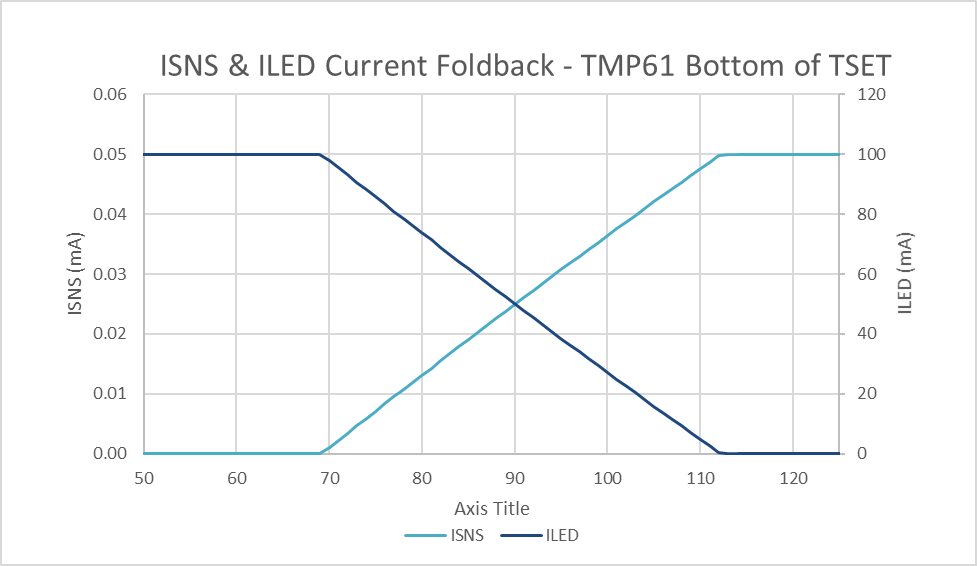

The LP886x-Q1 has an optional feature to decrease automatically LED current when LED overheating is detected with an external PTC sensor. An example of the behavior is shown in Figure 3-1. When the PTC temperature reaches T1, the LP886x-Q1 starts to decrease the LED current. When the LED current has reduced to 17.5% of the nominal value, current turns off until temperature returns to the operation range.

When external NTC (PTC) is connected, the pin current decreases LED output current. Temperature T1 and de-rate slope are defined by external resistors as explained below.

Parallel resistance of the PTC sensor and resistor R4 is calculated by formula:

- is the bias voltage of the resistor group. It is recommended to connect with chip's internal LDO output (pin 2)

| R1 | 5kΩ |

| RT | 6.5kΩ |

| R2 | 10kΩ |

| R3 | PTC |

| R4 | DNP |

| R5 | 1kΩ |

| RISET | 2.4kΩ |

The output current thermal foldback profile in Figure 3-3 is achieved:

Figure 3-3 Current Foldback Profile with

TMP61

Figure 3-3 Current Foldback Profile with

TMP61