SSZTA04 july 2017 ESD122 , TPD1S514 , TPD2S300

We’re starting to get used to seeing the USB Type-C® connector on laptops and even set-top boxes, but as it makes its way into small form-factor applications like mobile phones, wearables or other portable electronics, system designers have different design considerations. Their challenge is how to take advantage of a world of new features, including higher power delivery; reversible connectors; higher data rates; and the option of running alternate modes such as High-Definition Multimedia Interface (HDMI), DisplayPort and Thunderbolt, while continuing to minimize their own systems’ form factor and power consumption.

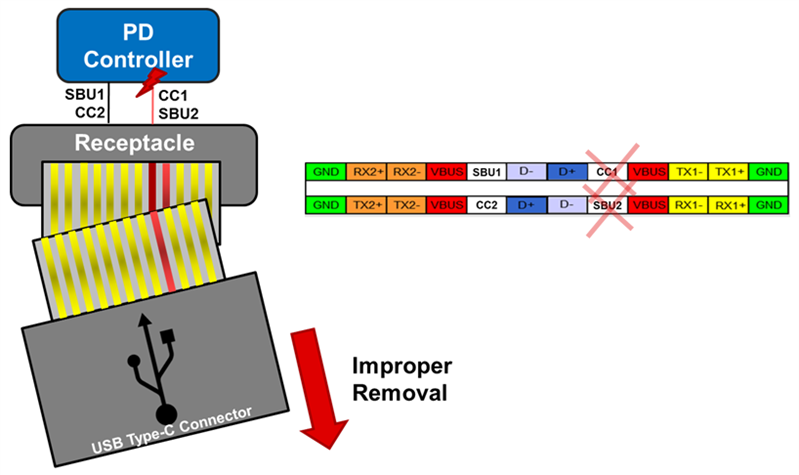

The new USB Type-C connector also has challenging protection considerations beyond the standard electrostatic discharge (ESD) protection for USB Type A or Micro-USB connectors. Since the pin pitch of the USB Type-C connector is so small, there’s an increased likelihood of shorting the higher-voltage VBUS power pin to the nearby data pins. And since the VBUS power pin can reach up to 20 V, 5 A with USB Power Delivery (PD), shorting VBUS to the configuration channel (CC) or sideband use (SBU) pins would be catastrophic to the downstream PD controller because the PD controllers are not rated to handle the higher voltages on these pins (Figure 1).

Figure 1 Shorting the vBUS

To the CC and SBU Pins Would Cause Failures to Downstream Circuitry

Figure 1 Shorting the vBUS

To the CC and SBU Pins Would Cause Failures to Downstream CircuitryIn mobile phone, wearable or other portable electronic device applications, the board-space and power-consumption constraints introduce several design challenges when implementing a solution to protect the PD controller from an overvoltage DC or transient event. For example:

- The solution has to be able to survive and protect downstream circuitry up to the maximum allowed charging voltage and current (20V and 5A), since there are noncompliant adapters on the market that can output 20V before even establishing a PD contract.

- The solution must be low power so that it does not deplete battery life, which is especially crucial in mobile and wearable applications.

- The solution must occupy a minimal footprint area on the board. Because of the dense pin count (24 pins) and fine pin pitch (0.5mm) of the USB Type-C connector, layout becomes a challenge when components take up too much area on the board.

With all of these factors in mind, Texas Instruments has created the TPD2S300: a single, small-footprint, low-power integrated solution to provide protection for the CC1 and CC2 pins on the USB Type-C controller.

The TPD2S300 is a two-channel integrated circuit that protects the CC1 and CC2 pins against transient ESD (up to ±8kV contact and ±15kV air gap) and overvoltage short circuits to VBUS (up to 20V). Unlike most standard external ESD devices, the integrated ESD in the TPD2S300 can withstand the higher working voltage. The TPD2S300 offers complete protection without the need for external ESD diodes or resistors. Its 1.4mm-by-1.4mm wafer chip-scale package (WCSP) offers a space-saving solution at a low quiescent current rating of 3µA, conserving power and extending battery life.

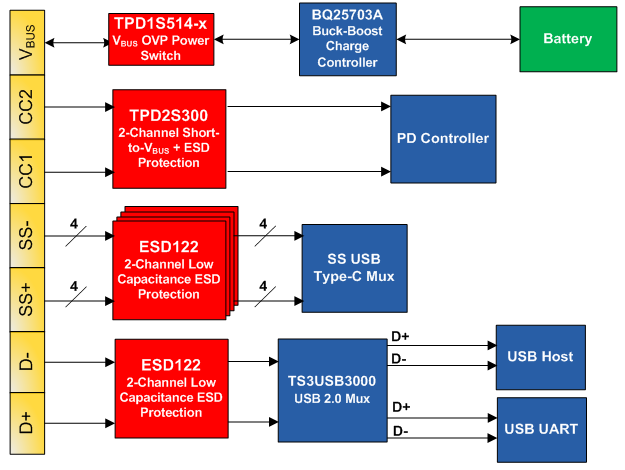

You can pair the TPD2S300 with other protection devices such as the TPD1S514 (overvoltage plus surge plus ESD protection for VBUS) and the ESD122 (two-channel low-capacitance ESD protection) to provide a complete solution for a USB Type-C connector (Figure 2).

Figure 2 Complete Solution for a USB

Type-C Connector

Figure 2 Complete Solution for a USB

Type-C ConnectorThe USB Type-C connector has opened up countless possibilities and opportunities for the technology world. However, with these benefits come protection challenges that can slow down the development of USB Type-C designs. These challenges can even end up causing field failures if not properly addressed. Texas Instruments has taken all of this into account and designed a small and easy integrated solution so you don’t have to.

Additional Resources

- Learn more about the TPD2S300 and ESD122

- Read the USB Type-C white paper

- Learn more about USB Type-C Protection