SSZTBM1 february 2016 LMT01

I’ve been getting a lot of questions about how to select a temperature sensor probe. The answer really depends on your application and the environment where the sensor will operate. In this post I’ll give an overview of three of the most popular sensor probe materials and their advantages for different environments. Let’s start with what a probe does.

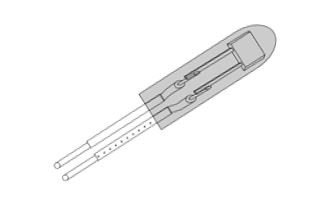

A temperature sensor probe is a temperature sensor integrated circuit (IC) encapsulated inside a case with wires that extend out to a receiver circuit. The case of the probe protects the temperature sensor IC from outside elements such as moisture, corrosive materials, and mechanical wear and tear. Figure 1 shows a conceptual drawing of a temperature sensor integrated inside a metal case.

Figure 1 Conceptual Drawing of a

Temperature Sensor in a Probe

Figure 1 Conceptual Drawing of a

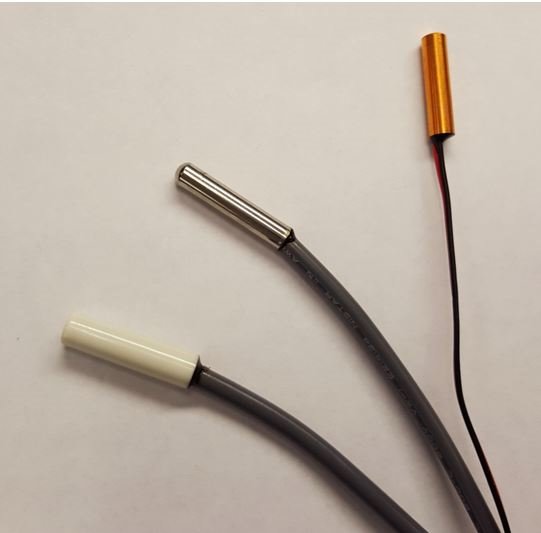

Temperature Sensor in a ProbeTo select a probe, think first about your end equipment and the environment where it will operate. Then you can choose a temperature sensor probe case from one of several materials (Figure 2):

- Plastic. Plastic probes are primarily used where cost is an important factor. A plastic exterior obviously cannot handle high temperature ranges, which makes this type of probe beneficial for cold-sensing applications such as refrigerators or cooling stations.

- Copper. The advantage of using a copper probe is its highly thermal conductive metal case, which yields quick thermal responses for applications where temperatures change quickly such as a radiator pipe. The disadvantage of using a copper probe is its cost and susceptibility to corrosion from moisture and oxidation (which creates the green stuff) when exposed to air for long periods of time.

- Stainless steel. Stainless steel probes exhibit the same thermal conductive properties but do not have corrosion or contamination issues. This type of probe is often in food preparation or medical uses where contamination of the probe material could be problematic.

Figure 2 Plastic, Stainless Steel, and

Copper Probes (from Left to Right)

Figure 2 Plastic, Stainless Steel, and

Copper Probes (from Left to Right)Regardless of the probe material, inside each probe is a temperature sensor IC. This sensor should have linear temperature accuracy across a wide temperature range for all sorts of applications. The package of the sensor should be small and thin enough to be encapsulated inside a case with as few wires as possible. In Figure 2, each probe was encapsulated with the 2-pin LMT01 temperature sensor.

In the above paragraphs, I mentioned only a few examples of different probe materials. What if I want to use a material I have never used before or determine if its structural integrity will survive extreme temperatures? I ran into these exact problems when these probes were presented to me. I tested the probes by connecting them to the LMT01EVM by soldering the end wires to the breakoff tab. Data was collected with the software GUI which automatically converted the pulse counts to temperature. With this tool I ran a series of tests to determine if a particular probe material was suitable to my application.

In conclusion, probe material selection depends on where and what the probe is sensing. Many of TI’s temperature sensors, like the LMT01, are accurate across a wide temperature range and can be used effectively in a variety of probe materials, depending on your end applications. For more information on TI’s temperature sensor ICs, download the LMT01 data sheet or search our temperature sensor portfolio.

Let me hear from you, what will you use a temperature sensor probe for? Please log in to share a comment below.

Additional Resources:

- Order the LMT01 evaluation module.

- Learn about TI’s temperature sensors.

- Read more blogs on temperature sensing.