SNIS139F February 2005 – January 2024 LM95231

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Pin Configuration and Functions

- 5 Specifications

- 6 Detailed Description

-

7 Registers

- 7.1 LM95231 Registers

- 7.2 Status Register

- 7.3 Configuration Register

- 7.4 Remote Diode Filter Control Register

- 7.5 Remote Diode Model Type Select Register

- 7.6 Remote TruTherm Mode Control

- 7.7 Local and Remote MSB and LSB Temperature Registers

- 7.8 Manufacturers ID Register

- 7.9 Die Revision Code Register

- 8 Application and Implementation

- 9 Layout

- 10Device and Documentation Support

- 11Revision History

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DGK|8

Thermal pad, mechanical data (Package|Pins)

Orderable Information

9.1 PCB Layout for Minimizing Noise

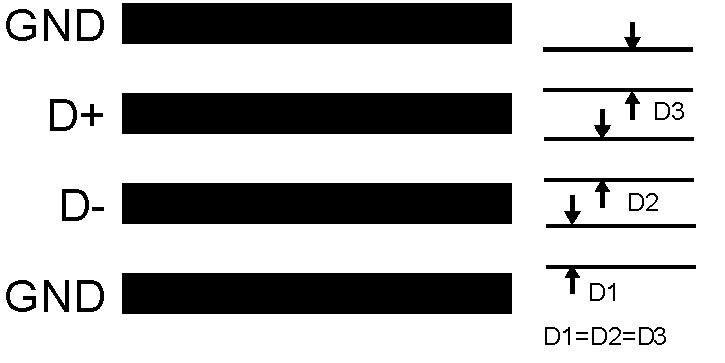

Figure 9-1 Ideal Diode Trace Layout

Figure 9-1 Ideal Diode Trace LayoutIn a noisy environment, such as a processor mother board, layout considerations are very critical. Noise induced on traces running between the remote temperature diode sensor and the LM95231 can cause temperature conversion errors. Keep in mind that the signal level the LM95231 is trying to measure is in microvolts. The following guidelines should be followed:

- VDD should be bypassed with a 0.1µF capacitor in parallel with 100pF. The 100pF capacitor should be placed as close as possible to the power supply pin. A bulk capacitance of approximately 10µF needs to be in the near vicinity of the LM95231.

- A 100pF diode bypass capacitor is recommended to filter high frequency noise but may not be necessary. Make sure the traces to the 100pF capacitor are matched. Place the filter capacitors close to the LM95231 pins.

- Ideally, the LM95231 should be placed within 10cm of the Processor diode pins with the traces being as straight, short and identical as possible. Trace resistance of 1Ω can cause as much as 0.62°C of error. This error can be compensated by using simple software offset compensation.

- Diode traces should be surrounded by a GND guard ring to either side, above and below if possible. This GND guard should not be between the D+ and D− lines. In the event that noise does couple to the diode lines it would be ideal if it is coupled common mode. That is equally to the D+ and D− lines.

- Avoid routing diode traces in close proximity to power supply switching or filtering inductors.

- Avoid running diode traces close to or parallel to high speed digital and bus lines. Diode traces should be kept at least 2cm apart from the high speed digital traces.

- If it is necessary to cross high speed digital traces, the diode traces and the high speed digital traces should cross at a 90 degree angle.

- The ideal place to connect the LM95231's GND pin is as close as possible to the Processors GND associated with the sense diode.

- Leakage current between D+ and GND and between D+ and D− should be kept to a minimum. Thirteen nano-amperes of leakage can cause as much as 0.2°C of error in the diode temperature reading. Keeping the printed circuit board as clean as possible will minimize leakage current.

Noise coupling into the digital lines greater than 400mVp-p (typical hysteresis) and undershoot less than 500mV below GND, may prevent successful SMBus communication with the LM95231. SMBus no acknowledge is the most common symptom, causing unnecessary traffic on the bus. Although the SMBus maximum frequency of communication is rather low (100kHz max), care still needs to be taken to ensure proper termination within a system with multiple parts on the bus and long printed circuit board traces. An RC lowpass filter with a 3db corner frequency of about 40MHz is included on the LM95231's SMBCLK input. Additional resistance can be added in series with the SMBDAT and SMBCLK lines to further help filter noise and ringing. Minimize noise coupling by keeping digital traces out of switching power supply areas as well as ensuring that digital lines containing high speed data communications cross at right angles to the SMBDAT and SMBCLK lines.