SLYA048B March 2020 – June 2021 FDC1004 , FDC1004-Q1 , FDC2112 , FDC2112-Q1 , FDC2114 , FDC2114-Q1 , FDC2212 , FDC2212-Q1 , FDC2214 , FDC2214-Q1 , LDC0851 , LDC1001 , LDC1041 , LDC1051 , LDC1101 , LDC1312 , LDC1312-Q1 , LDC1314 , LDC1314-Q1 , LDC1612 , LDC1612-Q1 , LDC1614 , LDC1614-Q1 , LDC2112 , LDC2114 , LDC3114 , LDC3114-Q1

- Trademarks

- 1Inductive and Capacitive Theory of Operation

- 2FDC: Capacitive Level Sensing

- 3LDC: Inductive Touch Buttons

- 4LDC: Incremental Encoder and Event Counting

- 5LDC: Metal Proximity Sensor

- 6Revision History

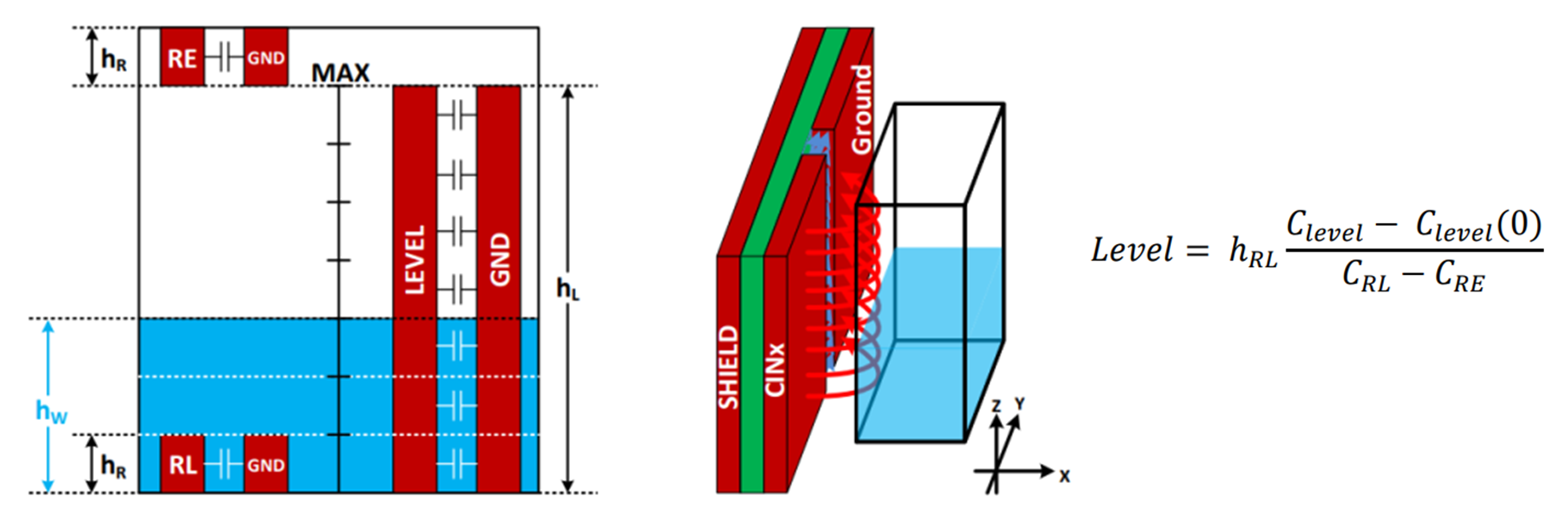

2 FDC: Capacitive Level Sensing

Capacitive level sensing allows for a contactless method of level sensing, enabling a more robust solution compared to mechanical level sensors that can be prone to rust. TI’s capacitive level sensing solution incorporates an active shield driver that can reduce the external interference from foreign objects, such as a human hand. The engineer can use shield drivers using an out-of-phase technique to further stabilize the measurements and maximize the SNR.

Common applications include: wiper fluid and coolant level detection, coffee makers, refrigerators, small fuel tanks, and 3D printers.

Figure 2-1 FDC Capacitive Level Sensing Application

Figure 2-1 FDC Capacitive Level Sensing Application