SLYA048B March 2020 – June 2021 FDC1004 , FDC1004-Q1 , FDC2112 , FDC2112-Q1 , FDC2114 , FDC2114-Q1 , FDC2212 , FDC2212-Q1 , FDC2214 , FDC2214-Q1 , LDC0851 , LDC1001 , LDC1041 , LDC1051 , LDC1101 , LDC1312 , LDC1312-Q1 , LDC1314 , LDC1314-Q1 , LDC1612 , LDC1612-Q1 , LDC1614 , LDC1614-Q1 , LDC2112 , LDC2114 , LDC3114 , LDC3114-Q1

- Trademarks

- 1Inductive and Capacitive Theory of Operation

- 2FDC: Capacitive Level Sensing

- 3LDC: Inductive Touch Buttons

- 4LDC: Incremental Encoder and Event Counting

- 5LDC: Metal Proximity Sensor

- 6Revision History

3.3 Device Selection

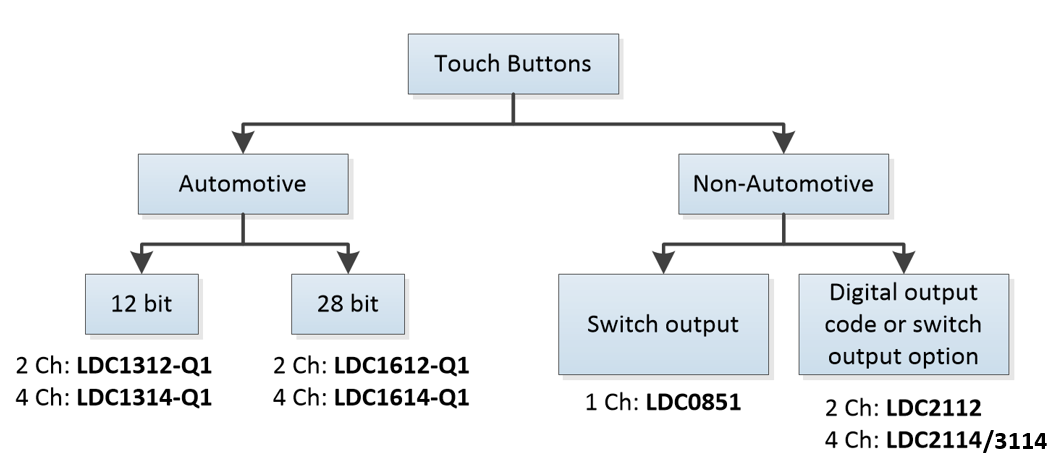

Figure 3-2 shows the device selection flow chart.

Figure 3-2 Inductive Touch Device Selection Flow Chart

Figure 3-2 Inductive Touch Device Selection Flow ChartTable 3-1 Device Recommendations

| Device | Features/Benefits |

|---|---|

| |

| |

| |

|