SNOA930C March 2015 – May 2021 LDC0851 , LDC1001 , LDC1001-Q1 , LDC1041 , LDC1051 , LDC1101 , LDC1312 , LDC1312-Q1 , LDC1314 , LDC1314-Q1 , LDC1612 , LDC1612-Q1 , LDC1614 , LDC1614-Q1 , LDC2112 , LDC2114 , LDC3114 , LDC3114-Q1

4.1 Example Design Procedure Using WEBENCH

WEBENCH provides two methods for PCB coil design. The first method finds a coil design that fits a specific application, in which the desired measurement capabilities are used to recommend a sensor.

The second method is an interactive design tool in which the coil size, shape, number of turns, and other parameters can be adjusted to optimize the sensor design to fit a specific need. This tool can be accessed at WEBENCH Inductor Design Tool.

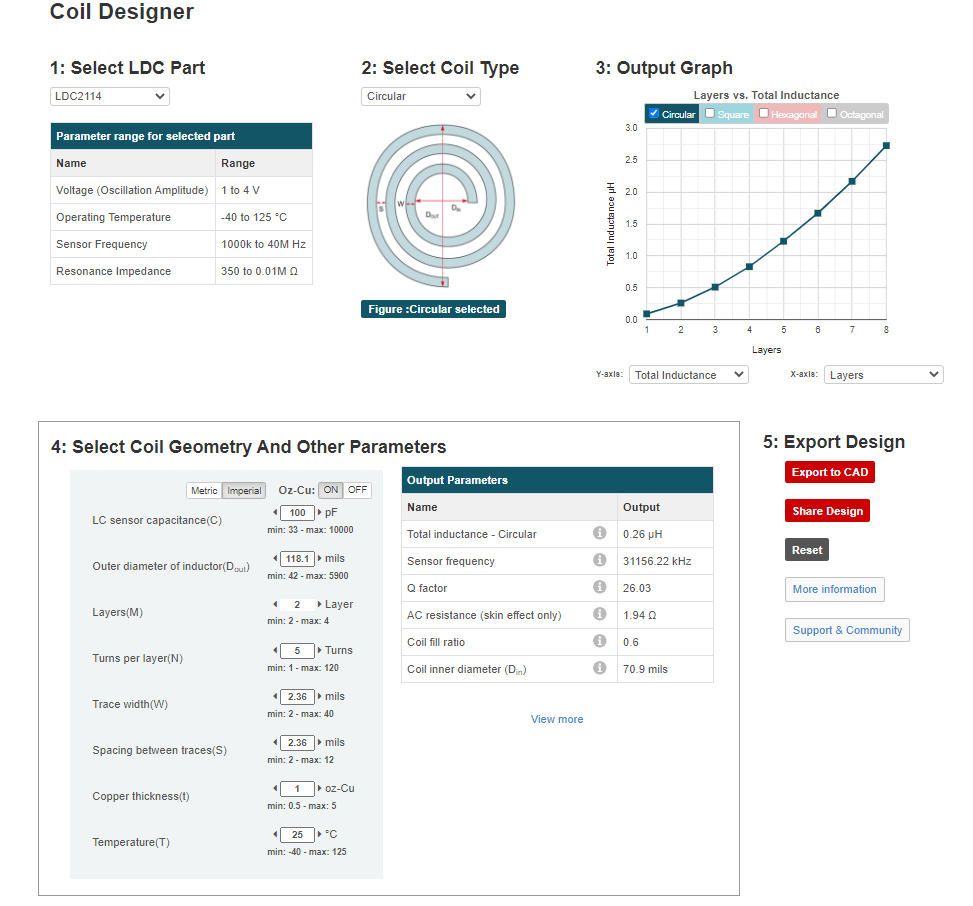

Figure 4-1 WEBENCH Coil Designer Tool

Figure 4-1 WEBENCH Coil Designer ToolThe top-middle pull-down menu selects the desired coil shape – choices include:

- Circular

- Square

- Hexagonal

- Octagonal

As discussed earlier, for most applications a circular sensor is the optimum shape, although square coils may be useful for smaller geometry sensors.

The lower-left section of the screen is where various sensor parameters can be entered and adjusted. Parameters to enter include the size, number of turns, and PCB fabrication characteristics.

The middle section reports the sensor characteristics based on the current settings.

Finally, the sensor design can be exported to the following output formats:

Altium Designer

Cadence Allegro 16.0-16.6

CadSoft EAGLE PCB (v6.4 or newer)

DesignSpark PCB

Mentor Graphics PADS PCB

The output can then be imported into CAD tools to complete a system design.