SSZT320 march 2020 TMS320F280021 , TMS320F280023 , TMS320F280023C , TMS320F280025 , TMS320F280025C

In the space of real-time power conversion that continuously demands higher performance and efficiency, it is critical for designers to invest in scalable and sustainable industrial and automotive power conversion solutions. This demand, in turn, leads to real-time control system requirements like the number of million instructions per second (MIPS), pulse-width modulators (PWMs) and analog-to-digital converters (ADCs) to increase within servo drive, power delivery, grid infrastructure and on-board charging applications. It also leads to developers’ need to build and maintain their lines of products with simplicity and low-risk. Performance scalability and portfolio compatibility provide developers a low-effort and cost-effective way to scale real-time control resources and maintain platforms of long-term power conversion solutions.

Scaling real-time control resources through distributed architectures

The rise of renewable energy is pushing the trend for higher power levels in applications like solar inverters. With the increase of power levels comes the need for more real-time control resources like MIPS, PWMs and ADCs, which play a critical role in the power conversion process. The typical way to address this need is through a single centralized controller – controlling the multiple power stages in the solar inverter system. What happens when this controller runs out of resources to address the higher power levels and the increasing number of power stages? The solution that designers have been looking for is distributed architecture.

The idea behind distributed architecture is the following: Connect multiple real-time control MCUs to scale the number of resources and peripherals available to your system. This implementation enables designers to achieve the performance and efficiency that is demanded from their products without compromising on

- Cost of a multi-chip solution

- Complexity of connecting multiple devices across isolation and the speed of the interface

- Lack of peripherals on host / master that has external memory interface

TI’s C2000 portfolio of real-time control MCUs brings the real value of power conversion through a distributed architecture implementation while addressing the 3 items listed above:

- TI’s latest edition to the C2000 real-time control MCU portfolio, the TMS320F28002x family, is low-cost and enables designers to optimize their BOM costs through distributed architecture. To even further optimize system cost, the remaining features that reside in the C2000 real-time control MCU portfolio, like accelerators, configurable logic, analog comparators and peripherals enable system-level integration.

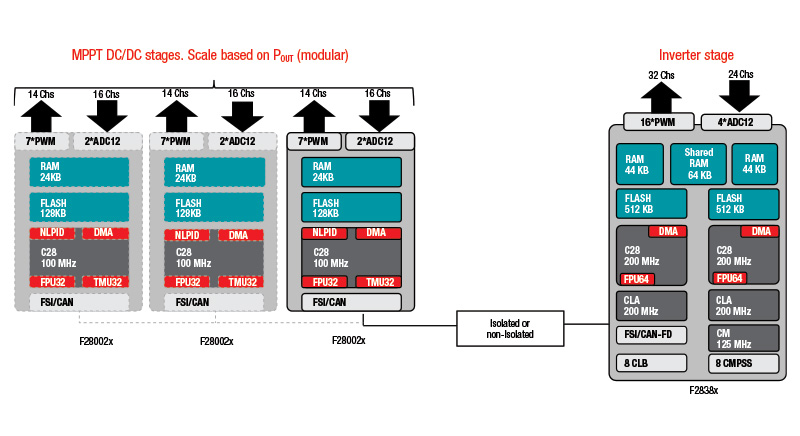

- The Fast Serial Interface (FSI) facilitates reliable and robust, high-speed chip-to-chip or board-to-board communication at up to 200 MBPS. FSI is advantageous compared to other interfaces like CAN or SCI, which are low speed and do not provide skew compensation, making them unfeasible options for connecting multiple MCUs across isolation. Due to skew compensation capability and speed that is inherent to FSI, it becomes a viable low-effort and robust interface option to connect multiple MCUs for resource scalability. Figure 1 shows how leveraging the FSI enables the connection of multiple real-time control MCUs for scalable MIPS, PWMs and ADCs in solar inverters and other applications.

- The Host Interface Controller (HIC), introduced in the F28002x, allows the MCU to act as a bridge, ultimately enabling the master processor to indirectly obtain FSI and other peripherals on the controller. Whether FSI is available on your host processor or not, the F28002x allows designers to achieve scalability through distributed architecture.

Figure 1 Leveraging FSI to connect multiple controllers for scalable resources

Figure 1 Leveraging FSI to connect multiple controllers for scalable resourcesEase migration and platform development through portfolio compatibility

Along with resource scalability, designers are faced with the challenge of building and maintaining platforms of products. To do so efficiently, there needs to be a low-effort and low-risk method to build lines of products from high-end to mid-end to low-end.

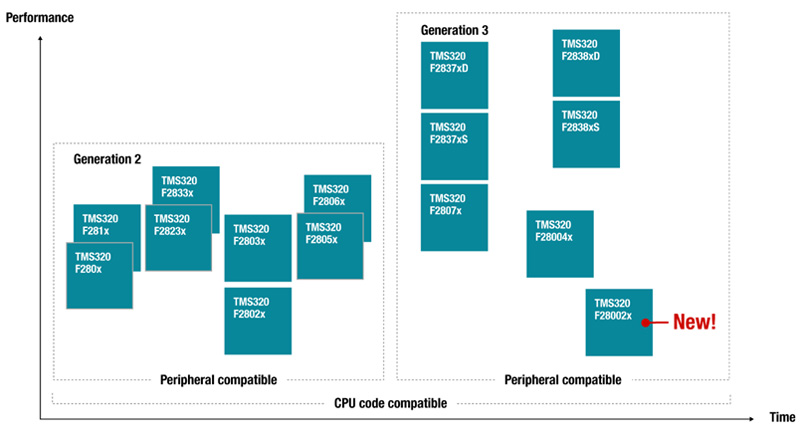

The C2000 real-time control MCU portfolio provides peripheral and code compatibility across device families, alleviating effort for developers working with a range of products. This simplifies the process to migrate and build a range of products based on similar MCU technology, enabling a sustainable platform solution. Figure 2 shows the portfolio of pin-to-pin, peripheral- and code- compatible device families within the third-generation of C2000 real-time control MCUs – ranging from high-end to mid-end to low-end.

Figure 2 Peripheral and code compatibility across the C2000 portfolio

Figure 2 Peripheral and code compatibility across the C2000 portfolioIn the evolving market of automotive and industrial power conversion, designers are looking for innovations that help them meet 2 critical design challenges: how to easily scale up real-time control resources, and how to build and maintain long-term, platform solutions. The connection of multiple C2000 real-time control MCUs through FSI for scalable MIPS, PWMs and ADCs in applications like solar inverters and distributed multi-axis servo drives is a low-effort, low-risk and cost-effective solution to scaling real-time control resources. At the same time, the code and peripheral compatibility of the device families within the C2000 portfolio enables the development of long-term platforms with low-effort and low-risk. The F28002x device family not only provides a cost-effective way to scale real-time control resources through distributed architecture, but adds to the existing compatible C2000 portfolio that enables designers to build long-term, sustainable solutions.

Additional resources

- Check out the F28002x product folder with data sheet, technical reference manual and samples.

- Check out our latest reference

designs:

- TIDM-02006, which features real-time control of distributed multi-axis servo through FSI, F2838x, and F28004x/F28002x.

- TIDM-1001: Two Phase Interleaved LLC Resonant Converter Reference Design for Automotive OBC/ DCDC and Server PSU applications using F28002x.

- Download these development kits: