SSZTCR7 may 2015 TDC1000 , TDC1000-Q1 , TMS320F28034

Austin, Texas has many attractions — music, technology and food, to name a few. But for visitors in the summer months, there is one attraction that no one should miss. Every day at dusk, up to 3 million bats fly out from under one of the city bridges and over a small lake, heading east to consume literally tons of mosquitoes and flying insects. Watching the cloud of bats fly out into the distance is a special privilege and should not be missed.

I am always amazed by the bats’ ability to do all their hunting using echolocation. Amazingly, human beings are just now catching up to use very similar technology to improve our lives. And this blog cover show we use ultrasonic sensing to better sense our world. Specifically, I’ll discuss the use of an ultrasonic sensor in liquids to measure levels, density and composition.

Liquid identification and level sensing have been used for decades in the technology that drives our world. Vehicles are probably the first example that comes to mind, but other applications abound. Environmental testing equipment, mining applications and numerous industrial processes depend on accurate measurement of the level, composition and density of liquids to get the job done.

Now that we can accomplish this using only a transducer and a few electrical components, miniaturization is enabling new applications to adopt the techniques. Home appliances, for example, are carefully measuring how much water and cleaning chemicals to use to generate the minimum amount of waste. Printer manufacturers not only need to tell customers when their ink is low, but they would also like to confirm customers are using their brand of ink.

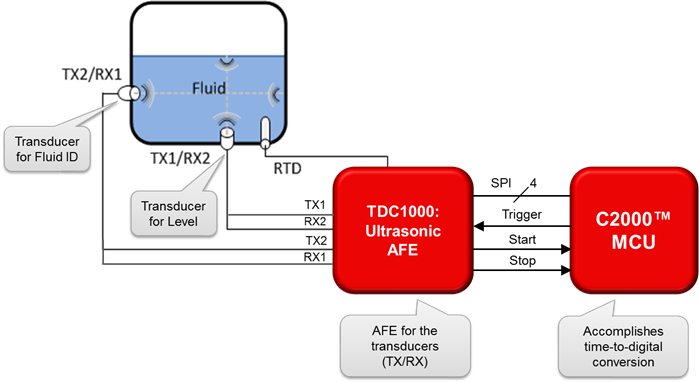

The good news for application developers is that Texas Instruments has released a winning combo of devices uniquely targeted for this space. The TDC1000 ultrasonic analog front end and the C2000 real-time microcontroller (MCU) provide the perfect solution for liquid level sensing and liquid identification applications. In fact, the C2000 MCU is the only one in the industry that combines connectivity with the ability to provide picosecond-level accuracy in sound measurements — without having to run at power-hungry and wallet-draining GHz speeds. Picoseconds may sound like overkill, but it makes the difference between being able to identify only the level and being able to identify the density of the liquid in question. These devices are also both AEC-Q100 certified, so application developers who have high temperature, high reliability requirements can really dig in with confidence.

TDC1000 ultrasonic analog front end + C2000 MCU block diagram: Fluid level / ID / concentration

To test out the combo, check out the evaluation kit here. And as always, please be sure to ask any questions in the comments section below!

For More Information

- Automotive Ultrasonic Fluid Level/Quality Measurement Reference Design