SWRA495K December 2015 – April 2024 CC1310 , CC1350 , CC2620 , CC2630 , CC2640 , CC2640R2F , CC2640R2F-Q1 , CC2642R-Q1 , CC2650 , CC2662R-Q1

- 1

- Abstract

- Trademarks

- 1Oscillator and Crystal Basics

- 2Overview of Crystal Oscillators for CC devices

- 3Selecting Crystals for the CC devices

- 4PCB Layout of the Crystal

- 5Measuring the Amplitude of the Oscillations of Your Crystal

- 6Crystals for CC13xx, CC26xx and CC23xx

- 7High Performance BAW Oscillator

- 8References

- 9Revision History

3.3 Load Capacitance

The crystal oscillator frequency is dependent on the capacitive loading of the crystal. The crystal data sheet provides the required load capacitance for the crystal, CL, for the oscillation to be at the correct frequency. The total CL consists of the loading capacitors and the parasitic capacitance of the layout and packaging. CL1 and CL2 are in series with respect to the crystal. Therefore, the effective load capacitance they present is CL1/2, assuming CL1=CL2. Extra capacitance between board traces that connect to the crystal will increase the effective CL.

Using external capacitors to get the correct frequency means that the internal caps must be set to minimum. For example, an application could use near minimum on-chip capacitance of approximately 2 pF and an off chip capacitance of 7 pF to provide CL=9pF to the crystal. Table 3-1 shows using external caps this way gives slightly worse frequency stability with temperature than using internal capacitors. Certain sub-1GHz users may need to use external load capacitors to reduce spurs at an offset of twice the crystal frequency from the RF carrier frequency.

| 9-pF Internal CL | Minimum Internal CL /External CL | |

|---|---|---|

| Frequency variation –40°C to +90°C | Set by crystal | Set by crystal + 5 ppm |

| Voltage accuracy, ppm/V | 6.9 | 9 |

The following presents the relative advantages of crystals with different CL values.

The disadvantages of lower CL are as follows:

- Crystals with < 7-pF CL are more difficult to source with short lead times.

- Frequency becomes more sensitive to changes in board capacitance as CL decreases. It is possible to meet frequency stability specifications with a CL as low as 3 pF.

- Lowering CL results in degraded RF phase noise.

Advantages of lower CL are as follows:

- Lower CL causes a much faster start-up time. (Start-up time is proportional to CL2.)

- Lower CL causes a faster amplitude control loop response time.

- Lower CL makes it easier to use small size crystals (2.0 × 1.6 and so on) and maintain a start-up time at or less than 400 µs. Start-up time worsens with smaller crystals due to an increase in LM.

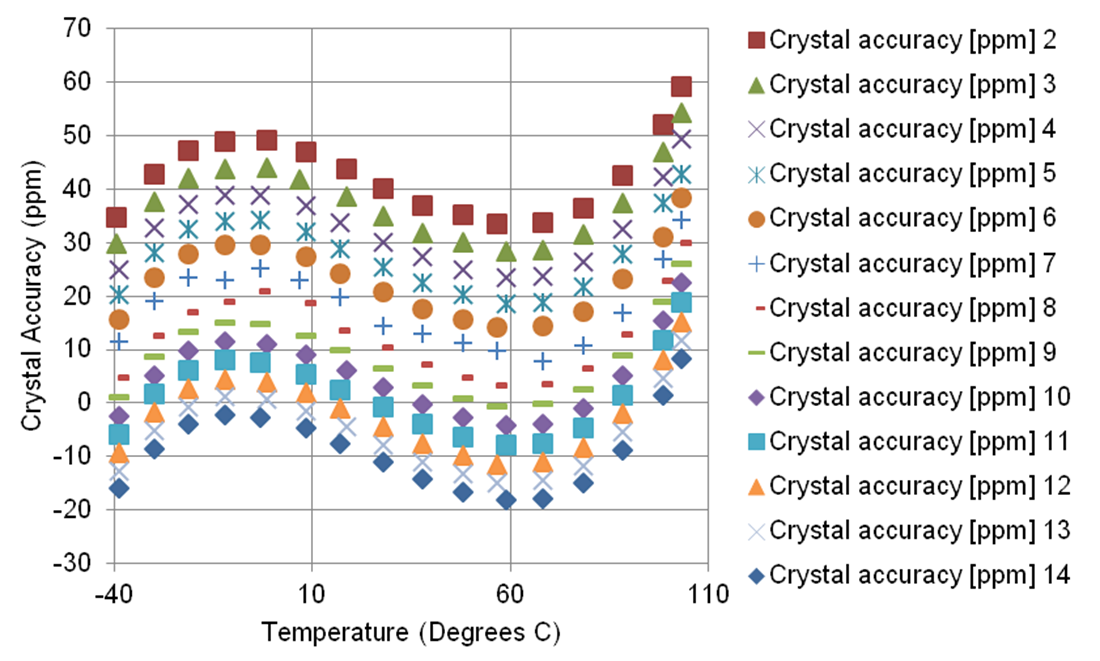

The internal load capacitance has no appreciable impact on the shape of the frequency vs temperature of the high frequency crystal. This can be seen by looking at the following two plots. Figure 3-2 shows the frequency versus temperature curve for the crystal using 13 different but closely spaced load capacitance. Each different load capacitance shifts the curve up or down, but does not change the overall shape of the curve. This can be seen by removing the offset of each curve, as shown in Figure 3-3.

Figure 3-2 The Frequency vs Temperature Curve for the High Frequency Crystal for 13 Closely Spaced Load Capacitance Values

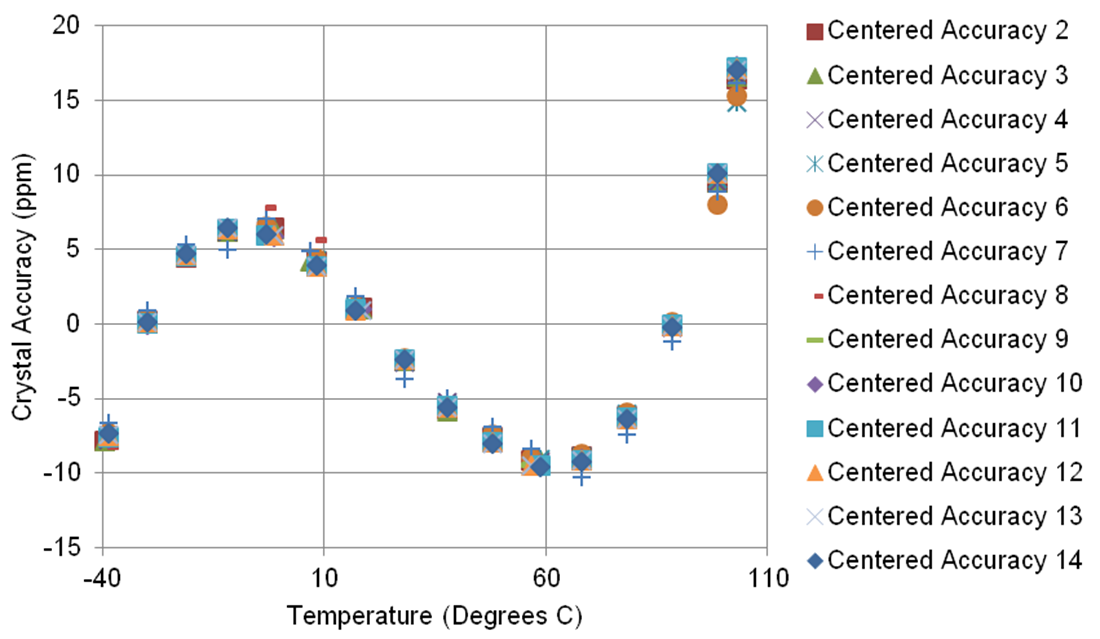

Figure 3-2 The Frequency vs Temperature Curve for the High Frequency Crystal for 13 Closely Spaced Load Capacitance Values Figure 3-3 Removing the Offset of the Frequency vs Temperature Curves

Figure 3-3 Removing the Offset of the Frequency vs Temperature CurvesFigure 3-3 shows that a change in the internal load capacitance does not influence the shape of the frequency vs temperature curve. This indicates that the internal load capacitors have minimal impact on this curve.

A method to change the on-chip load caps of the crystal is discussed in CC13xx/CC26xx Hardware Configuration and PCB Design Considerations.