SSZTC91 August 2015 TMS320F28379D

Motor position encoders are widely used in industrial motor control applications such as servo drives, robotics, machine tools, printing machines, textile machines and elevators. Interfacing these encoders to the rest of your system can raise some tricky electromagnetic compatibility (EMC) issues. To help you meet these challenges, I’ll begin this series with an overview of the various types of motor position encoders and their interface, and the rest of the series will dive into designing an industrial EMC-compliant interface to each of the various motor position encoder types.

Depending on the industrial drive’s application, the required position/angle resolution can vary from a few bits to 25 bits and beyond. Some drive applications even require the number of angular turns. The mounting distance from the frequency inverter to the position encoder can vary from very short – a few meters in multi-axis drives – to 100m and beyond. Due to that long distance the electrical interface needs to be designed for robust data transmission with high immunity against electromagnetic fields, common mode voltage, impulse noise, etc.

Figure 1 shows several types of linear or angle position feedback encoders for industrial applications.

Figure 1 Position Feedback Encoders and

Their Corresponding Interfaces

Figure 1 Position Feedback Encoders and

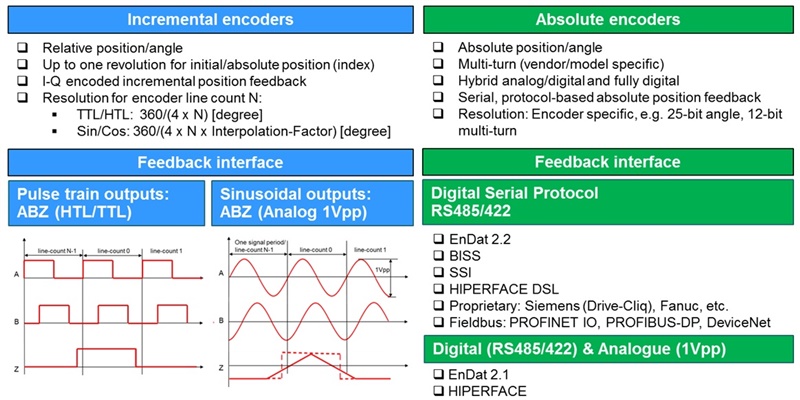

Their Corresponding InterfacesThere are two types of position encoders: incremental and absolute. Incremental encoders provide information on the incremental position or angle change. After power-up they do not provide the absolute position, although it is still possible to obtain through the index signal after one mechanical revolution. Absolute encoders always provide the absolute mechanical position.

Incremental encoders exhibit three differential signals: A, B and Z. A and B encode the incremental position change. The position resolution depends on the line count of the incremental encoder. A typical range is 50 to 10,000 line counts per revolution. Z typically occurs once per revolution and is a “home index” used to derive the absolute position.

Incremental encoder interfaces are either digital pulse train with transistor-transistor logic (TTL)- or high-threshold logic (HTL)-compatible digital output levels or analog sine/cosine outputs with 1Vpp or 11µApp amplitude. Encoders with analog outputs are often referred to as sin/cos encoders and allow for much higher resolution than encoders with TTL/HTL output because you can interpolate its position within one line count by using the inverse tangent function with the measured sine and cosine signals. This interpolation can increase the resolution by as much as 16 bits, with a possible total resolution of 25 bits or more. The frequency of the output signals is proportional to the line count of the selected encoder times the rotation speed.

Absolute position feedback encoders provide the absolute position with up to 25-bit resolution and more. Their electrical interface has evolved from a hybrid analog and digital protocol-based serial interface to a pure digital protocol-based serial interface. The standards for serial communication are typically vendor-specific and leverage RS-485 or RS-422 differential signaling with bidirectional data transfer. For example, EnDat 2.2 not only transmits the absolute position, but also allows readout from and writing to the encoder’s internal memory. You can select the type of data transmitted – absolute position, turns, temperature, further parameters, diagnostics – through mode commands that the subsequent electronics, often referred to as the EnDat 2.2 master, send to the EnDat2.2 encoder.

Pure digital serial protocol-based standards like EnDat2.2, BiSS® and HIPERFACE DSL® are capable of compensating for the propagation delay and supporting communication over a cable length of up to 100m. Pure digital protocols have a constant clock frequency, which does not change with rotation speed. For most protocols, you can select the clock frequency/baud rate to adapt to external factors, like cable length.

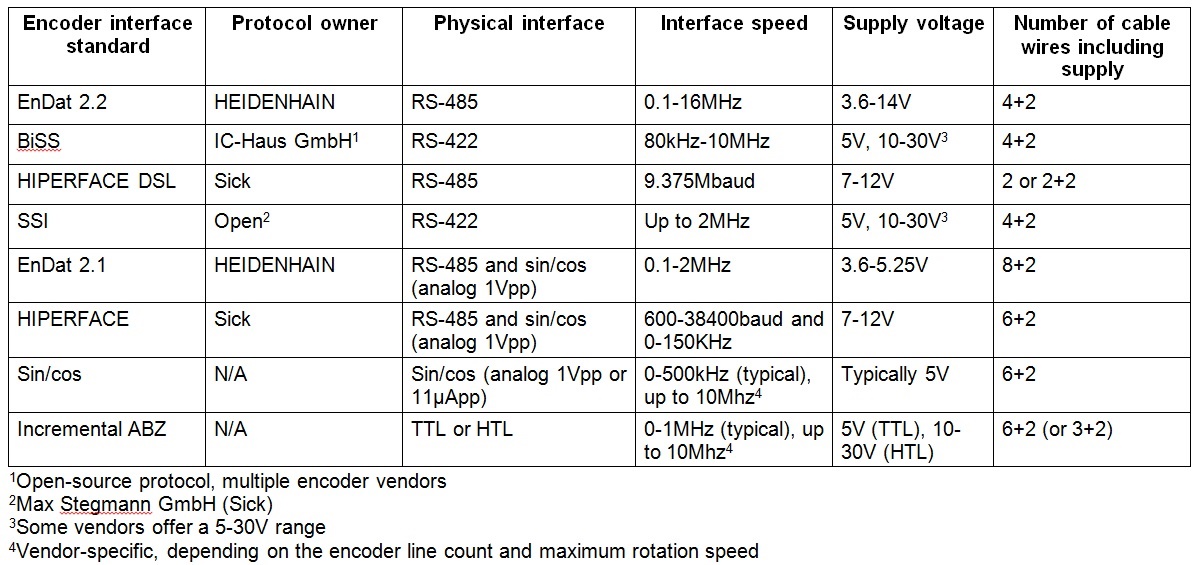

Encoders with a mixed analog and digital communication interface or a pure digital communication interface typically have a vendor-specific supply-voltage range. Table 1 is an overview of widely used encoder standards.

|

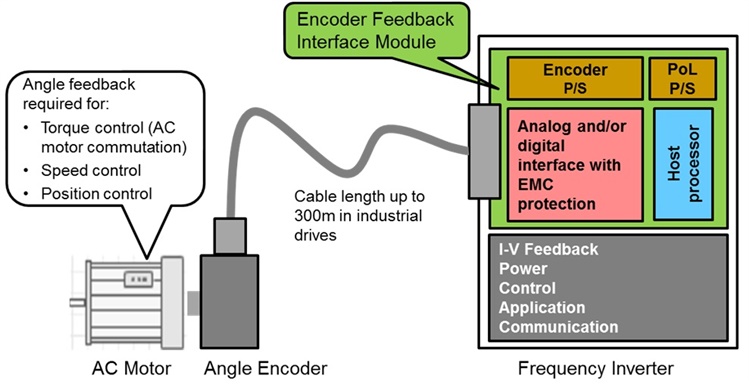

When interfacing any of these encoders to a frequency inverter for closed-loop control, the position interface module incorporates the following functional blocks, as shown in Figure 2:

- A physical analog or digital interface.

- Electromagnetic compatibility (EMC) according to IEC 61800-3.

- A power supply.

- Signal processing for position decoding and/or a digital protocol master.

Figure 2 Simplified Block Diagram

of a Position Feedback Interface Module on an Industrial Drive/frequency

Inverter

Figure 2 Simplified Block Diagram

of a Position Feedback Interface Module on an Industrial Drive/frequency

InverterIncremental digital HTL/TTL encoders and absolute digital encoders with the RS-485 or 422 interface require a lower hardware interface effort, while analog sin/cos encoders require an analog signal chain with a dual analog-to-digital converter. You need to design the physical interface to meet EMC immunity requirements like electrostatic discharge (ESD), electrical fast transient (EFT) bursts and surge with levels defined in IEC61800-3:

- ESD: ±4kV, direct-contact discharge or ±8kV air discharge.

- EFT: ±2kV, 5kHz, through a capacitive coupling clamp.

- Surge: ±1kV, 2-Ω source impedance, coupling through the cable shield.

TTL/HTL encoders require the lowest signal-processing effort, requiring only a directional quadrature pulse counter. Incremental sin/cos encoders require signal processing to calculate the inverse tangent for interpolation in addition to the quadrature counter. Digital serial interface protocol-based standards require high signal-processing effort and are typically implemented on FPGAs, or more recently on innovative processors like the Sitara™ AM437x, which leverages the programmable real-time unit subsystem and industrial communication subsystem (PRU-ICSS) peripheral.

In the next installment of this series, my colleagues and I will take a closer look at each encoder interface and provide details on how to implement an industrial, EMC-compliant interface to a BiSS-C position encoder/BiSS-C master interface.

If you’re ready to start designing, check out these TI Designs reference designs for interfaces to EnDat2.2, BiSS, HIPERFACE DSL and sin/cos encoders. Please go to ti.com/tidesigns and search for the corresponding encoder standard.

If you would like to see this series touch on specific topics related to position encoder interface design, please log in to post a comment below.

Additional Resources

- Read Ian Williams’ blog series explaining industrial EMC testing on Precision Hub.

- For more information on interfacing with position sensors, check out the DesignDRIVE development platform.

- Also, the industrial servo and AC inverter drive reference design can be adapted to interface with a host port interface as well as the universal digital interface reference design.