SNVS115E April 2000 – June 2019 LM2587

PRODUCTION DATA.

- 1 Features

- 2 Typical Applications

- 3 Description

- 4 Revision History

- 5 Pin Configurations

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESDRatings

- 6.3 Recommended Operating Ratings

- 6.4 Thermal Information

- 6.5 Electrical Characteristics: 3.3 V

- 6.6 Electrical Characteristics: 5 V

- 6.7 Electrical Characteristics: 12 V

- 6.8 Electrical Characteristics: Adjustable

- 6.9 Electrical Characteristics: All Output Voltage Versions

- 6.10 Typical Characteristics

- 7 Detailed Description

- 8 Application And Implementation

- 9 Layout

- 10Device and Documentation Support

- 11Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

- KTT|5

Orderable Information

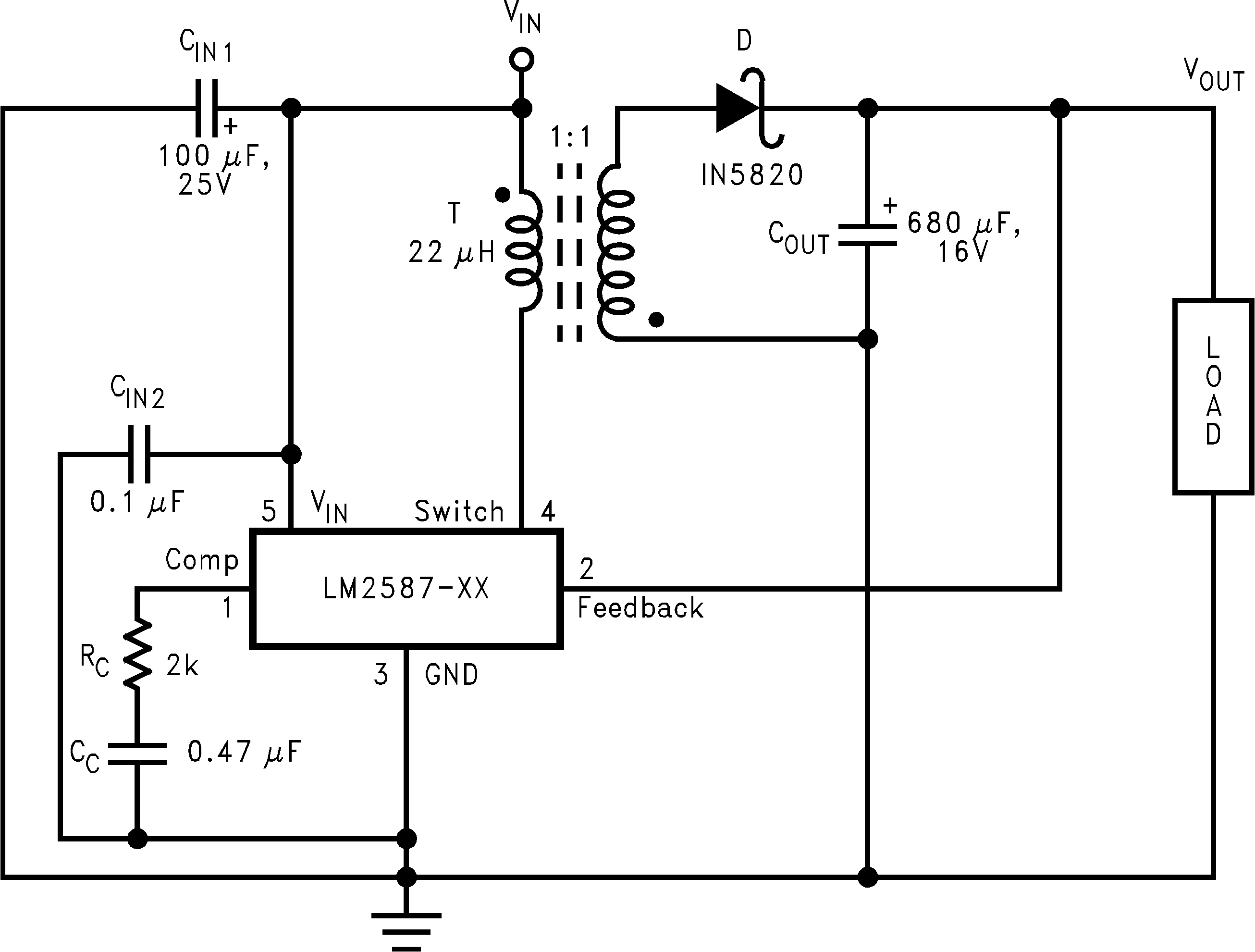

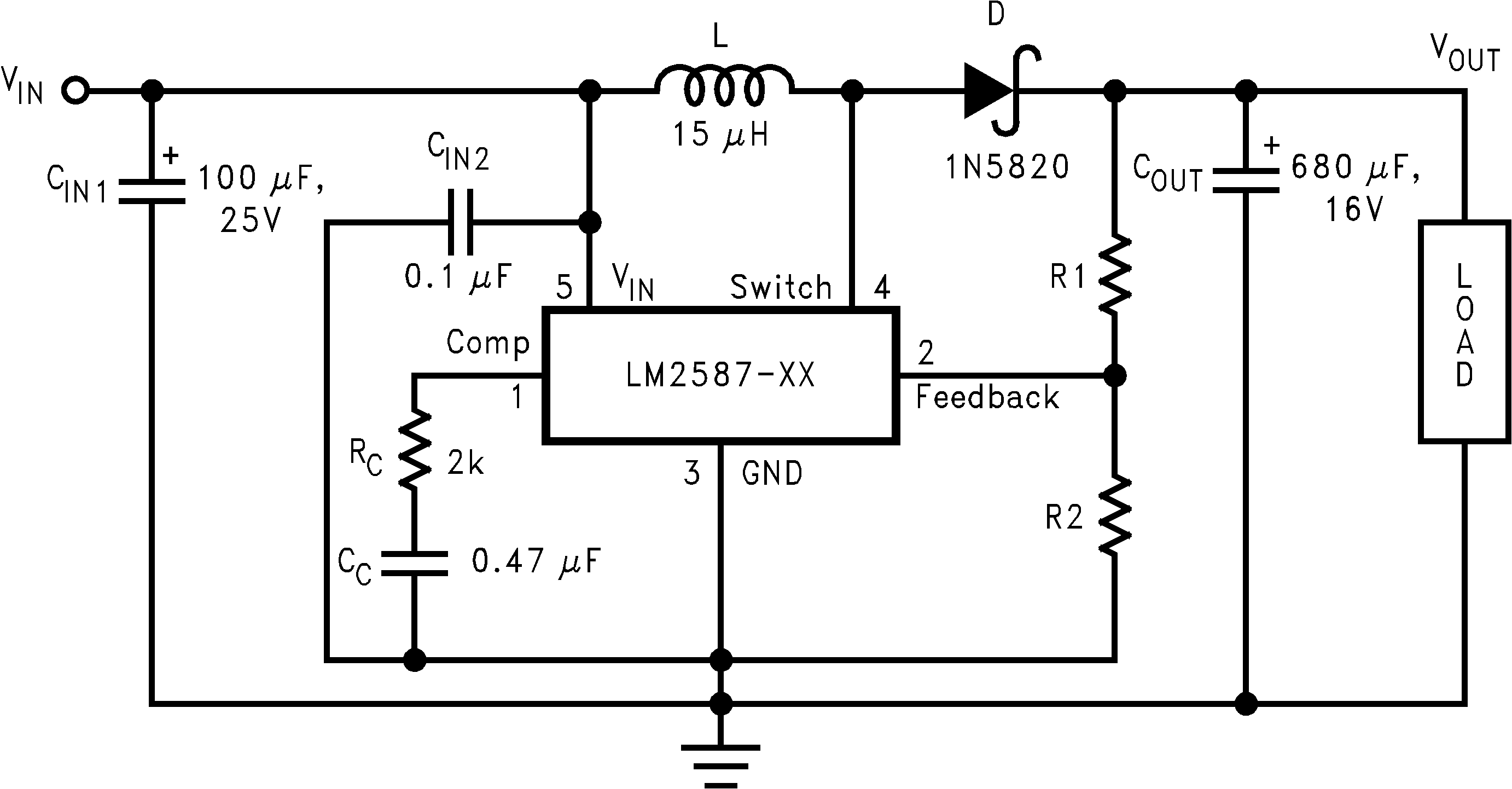

8.3.1 Test Circuits

CIN1—100 μF, 25V Aluminum Electrolytic CIN2—0.1 μF CeramicT—22 μH, 1:1 Schott #67141450D—1N5820COUT—680 μF, 16V Aluminum Electrolytic CC—0.47 μF Ceramic RC—2k

Figure 61. LM2587-3.3 and LM2587-5.0 Test Circuit

CIN1—100 μF, 25V Aluminum Electrolytic CIN2—0.1 μF CeramicL—15 μH, Renco #RL-5472-5D—1N5820COUT—680 μF, 16V Aluminum Electrolytic CC—0.47 μF Ceramic RC—2kFor 12V Devices: R1 = Short (0Ω) and R2 = Open For ADJ Devices: R1 = 48.75k, ±0.1% and R2 = 5.62k, ±1%

Figure 62. LM2587-12 and LM2587-ADJ Test Circuit