SNVS114G May 1999 – February 2015 LM3940

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

Orderable Information

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

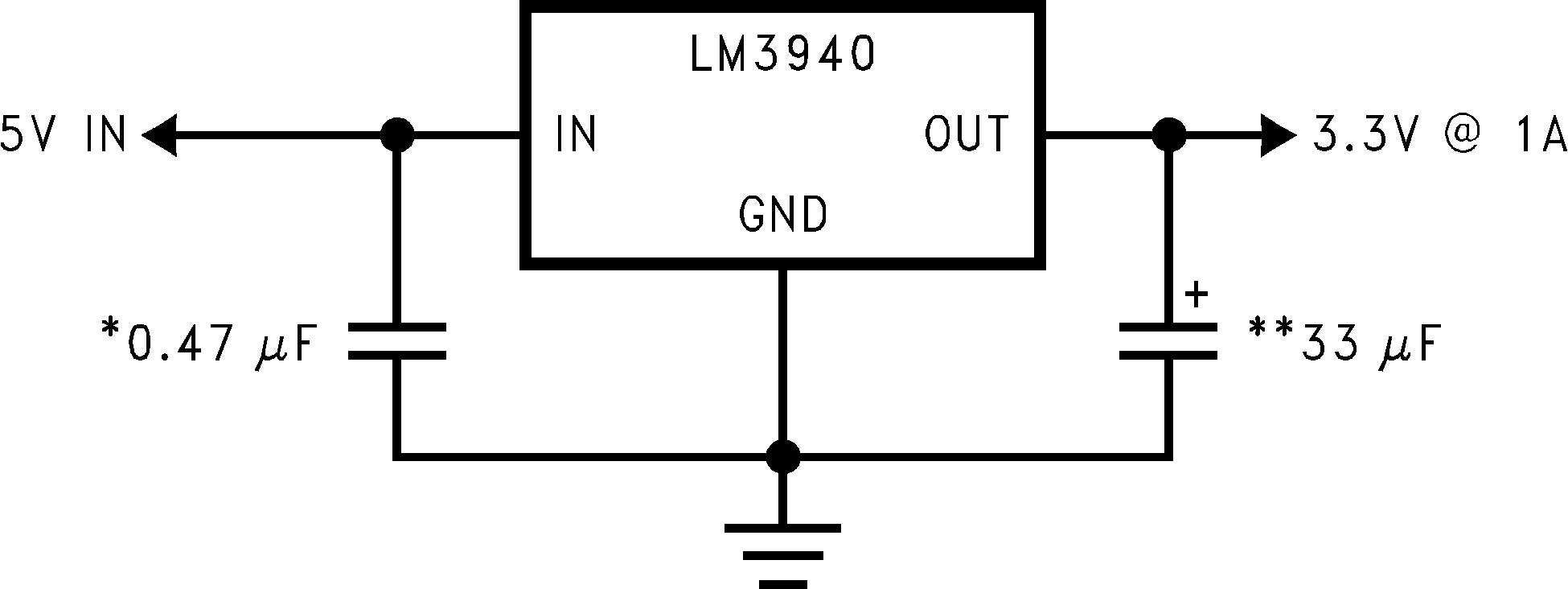

The LM3940 is a linear voltage regulator operating from 5 V on the input and regulates voltage to 3.3V with 1-A maximum output current. This device is suited for system which contain both 5-V and 3.3-V logic, with prime power provided from a 5-V bus.

8.2 Typical Application

**See Detailed Design Procedure.

8.2.1 Design Requirements

| DESIGN PARAMETER | EXAMPLE VALUE |

|---|---|

| Input voltage | 5 V, ± 10% |

| Output voltage | 3.3 V, ±3% |

| Output current | 1 A |

8.2.2 Detailed Design Procedure

8.2.2.1 External Capacitors

The output capacitor is critical to maintaining regulator stability, and must meet the required conditions for both equivalent series resistance (ESR) and minimum amount of capacitance.

8.2.2.1.1 Minimum Capacitance

The minimum output capacitance required to maintain stability is 33 μF (this value may be increased without limit). Larger values of output capacitance will give improved transient response.

8.2.2.1.2 ESR Limits

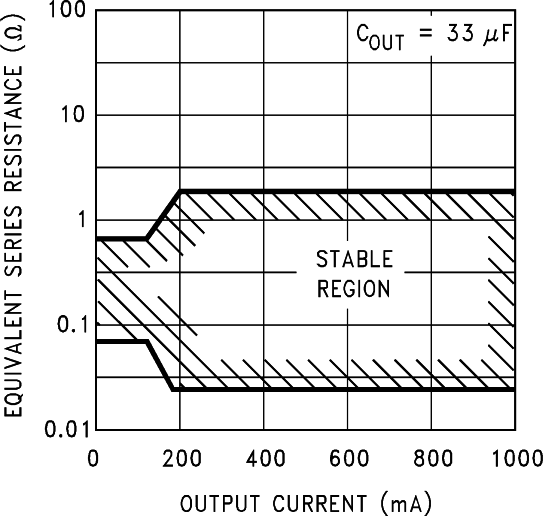

The ESR of the output capacitor will cause loop instability if it is too high or too low. The acceptable range of ESR plotted versus load current is shown in Figure 12. It is essential that the output capacitor meet these requirements, or oscillations can result.

Figure 12. ESR Limits

Figure 12. ESR Limits

It is important to note that for most capacitors, ESR is specified only at room temperature. However, the designer must ensure that the ESR will stay inside the limits shown over the entire operating temperature range for the design.

For aluminum electrolytic capacitors, ESR will increase by about 30X as the temperature is reduced from 25°C to −40°C. This type of capacitor is not well-suited for low temperature operation.

Solid tantalum capacitors have a more stable ESR over temperature, but are more expensive than aluminum electrolytics. A cost-effective approach sometimes used is to parallel an aluminum electrolytic with a solid tantalum, with the total capacitance split about 75/25% with the aluminum being the larger value.

If two capacitors are paralleled, the effective ESR is the parallel of the two individual values. The “flatter” ESR of the Tantalum will keep the effective ESR from rising as quickly at low temperatures.

8.2.3 Application Curves

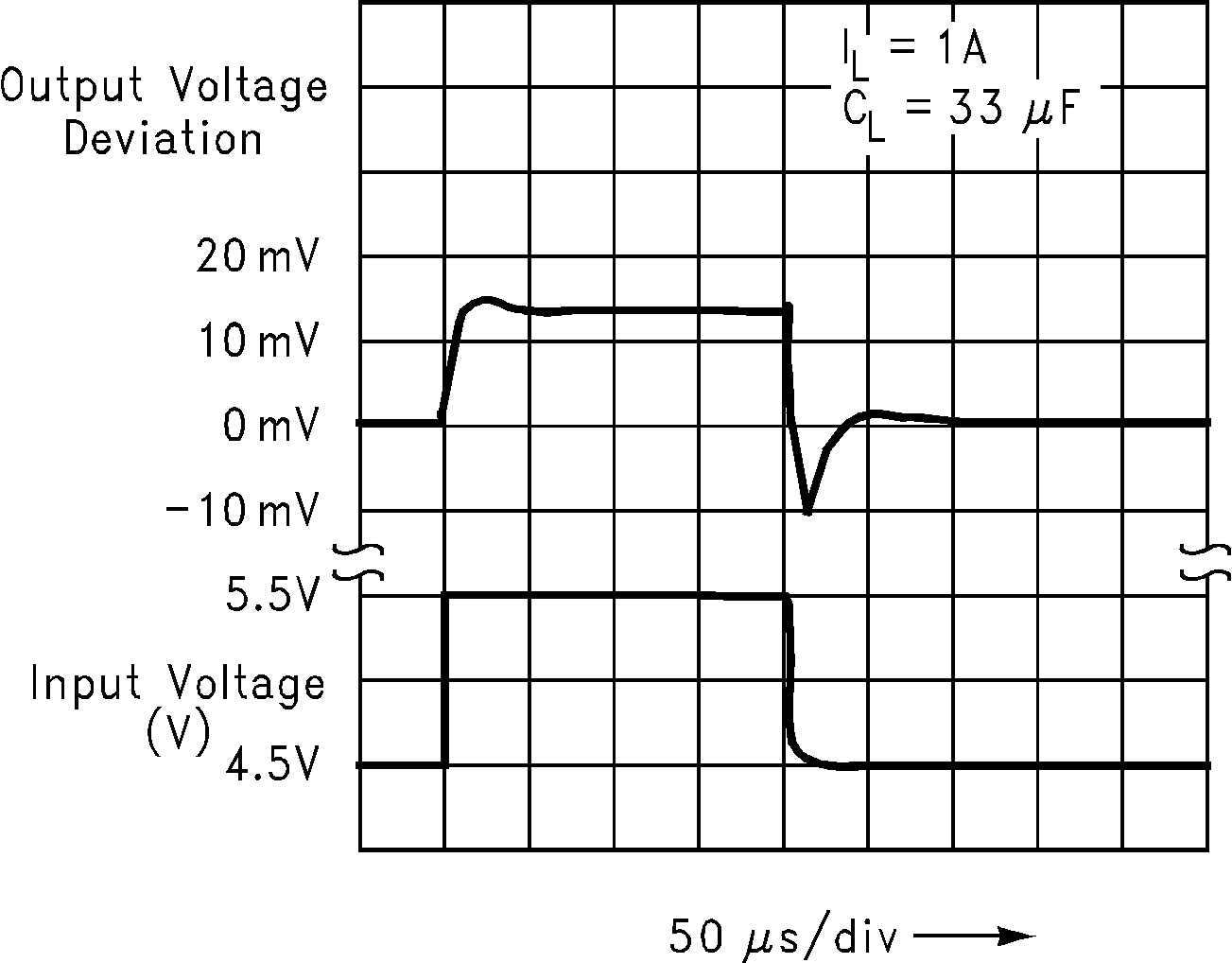

Figure 13. Line Transient Response

Figure 13. Line Transient Response

Figure 14. Load Transient Response

Figure 14. Load Transient Response