SLVS427D JUNE 2002 – May 2015 TPS61120 , TPS61121 , TPS61122

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Options

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Parameter Measurement Information

- 9 Detailed Description

-

10Application and Implementation

- 10.1 Application Information

- 10.2

Typical Applications

- 10.2.1 Solution for Maximum Output Power

- 10.2.2 Low Profile Solution, Maximum Height 1.8 mm

- 10.2.3 Dual Power Supply With Auxiliary Positive Output Voltage

- 10.2.4 Dual Power Supply With Auxiliary Negative Output Voltage

- 10.2.5 Single Output Using LDO as Filter

- 10.2.6 Dual Input Power Supply Solution

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- PW|16

Thermal pad, mechanical data (Package|Pins)

Orderable Information

10 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

10.1 Application Information

The TPS6112x DC-DC converters are intended for systems powered by a dual or triple cell NiCd or NiMH battery with a typical terminal voltage between 1.8 V and 5.5 V. They can also be used in systems powered by one-cell Li-Ion with a typical stack voltage between 2.5 V and 4.2 V. Additionally, two or three primary and secondary alkaline battery cells can be the power source in systems where the TPS6112x is used.

The built-in LDO can be used to generate a second output voltage derived from the DC-DC converter output, from the battery, or from another power source like an ac adapter or a USB power rail. The maximum programmable output voltage at the LDO is 5.5 V.

10.2 Typical Applications

10.2.1 Solution for Maximum Output Power

Figure 17. Solution for Maximum Output Power

Figure 17. Solution for Maximum Output Power

10.2.1.1 Design Requirements

For this design example, use the parameters listed in Table 3.

Table 3. TPS6112x 5 V Output Design Parameters

| DESIGN PARAMETERS | EXAMPLE VALUES |

|---|---|

| Input voltage range | 1.8 V to 3.3 V |

| Output voltage boost | 3.3 V |

| Output voltage LDO | 1.5 V |

| Output voltage ripple | ±3% VO |

| Transient response | ±10% VO |

| Input voltage ripple | ±200 mV |

10.2.1.2 Detailed Design Procedure

The TPS6112x DC-DC converters are intended for systems powered by a dual or triple cell NiCd or NiMH battery with a typical terminal voltage between 1.8 V and 5.5 V. They can also be used in systems powered by one-cell Li-Ion with a typical stack voltage between 2.5 V and 4.2 V. Additionally, two or three primary and secondary alkaline battery cells can be the power source in systems where the TPS6112x is used.

10.2.1.2.1 Programming the Output Voltage

10.2.1.2.1.1 DC-DC Converter

The output voltage of the TPS61120 DC-DC converter section can be adjusted with an external resistor divider. The typical value of the voltage on the FB pin is 500 mV. The maximum allowed value for the output voltage is 5.5 V. The current through the resistive divider should be about 100 times greater than the current into the FB pin. The typical current into the FB pin is 0.01 µA and the voltage across R6 is typically 500 mV. Based on those two values, the recommended value for R6 should be lower than 500 kΩ, in order to set the divider current at 1 µA or higher. Because of internal compensation circuitry the value for this resistor should be in the range of 200 kΩ. From that, the value of resistor R3, depending on the needed output voltage (VO), can be calculated using Equation 1:

If as an example, an output voltage of 3.3 V is needed, a 1-MΩ resistor should be chosen for R3. If for any reason the value for R6 is chosen significantly lower than 200 kΩ additional capacitance in parallel to R3 is recommended. The required capacitance value can be easily calculated using Equation 2.

Figure 18. Typical Application Circuit for Adjustable Output Voltage Option

Figure 18. Typical Application Circuit for Adjustable Output Voltage Option

10.2.1.2.1.2 LDO

Programming the output voltage at the LDO follows almost the same rules as in the DC-DC converter section. The maximum programmable output voltage at the LDO is 5.5 V. Since reference and internal feedback circuitry are similar, as they are at the boost converter section, R4 also should be in the 200-kΩ range. The calculation of the value of R5 can be done using the following Equation 3:

If as an example, an output voltage of 1.5 V is needed, a 360 kΩ-resistor should be chosen for R5.

10.2.1.2.2 Programming the LBI/LBO Threshold Voltage

The current through the resistive divider should be about 100 times greater than the current into the LBI pin. The typical current into the LBI pin is 0.01 µA, and the voltage across R2 is equal to the LBI voltage threshold that is generated on-chip, which has a value of 500 mV. The recommended value for R2is therefore in the range of 500 kΩ. From that, the value of resistor R1, depending on the desired minimum battery voltage VBAT, can be calculated using Equation 4.

The output of the low battery supervisor is a simple open-drain output that goes active low if the dedicated battery voltage drops below the programmed threshold voltage on LBI. The output requires a pullup resistor with a recommended value of 1 MΩ. The maximum voltage which is used to pull up the LBO outputs should not exceed the output voltage of the DC-DC converter. If not used, the LBO pin can be left floating or tied to GND.

10.2.1.2.3 Inductor Selection

A boost converter normally requires two main passive components for storing energy during the conversion. A boost inductor and a storage capacitor at the output are required. To select the boost inductor, it is recommended to keep the possible peak inductor current below the current limit threshold of the power switch in the chosen configuration. For example, the current limit threshold of the TPS6112x's switch is 1600 mA at an output voltage of 3.3 V. The highest peak current through the inductor and the switch depends on the output load, the input (VBAT), and the output voltage (VOUT). Estimation of the maximum average inductor current can be done using Equation 5:

For example, for an output current of 250 mA at 3.3 V, at least 575 mA of current flows through the inductor at a minimum input voltage of 1.8 V.

The second parameter for choosing the inductor is the desired current ripple in the inductor. Normally, it is advisable to work with a ripple in the range of 20% of the average inductor current. A smaller ripple reduces the magnetic hysteresis losses in the inductor, as well as output voltage ripple and EMI. But in the same way, regulation time at load changes rises. In addition, a larger inductor increases the total system costs. With those parameters, it is possible to calculate the value for the inductor by using Equation 6:

Parameter f is the switching frequency and Δ IL is the ripple current in the inductor, that is, 20% × IL. In this example, the desired inductor value is in the range of 14 µH. In typical applications a 10 µH inductor is recommended. The minimum possible inductor value is 4.7 µH. With the calculated inductance value and current, it is possible to choose a suitable inductor. Care must be taken that load transients and losses in the circuit can lead to higher currents as estimated in Equation 5. Also, the losses in the inductor caused by magnetic hysteresis losses and copper losses are a major parameter for total circuit efficiency.

The following inductor series from different suppliers have been used with the TPS6112x converters:

Table 4. List of Inductors

| VENDOR | RECOMMENDED INDUCTOR SERIES |

|---|---|

| Sumida | CDRH5D18 |

| CDRH6D28 | |

| Wurth Electronik | 7447789___ |

| 7447779___ | |

| Coiltronics | DR73 |

| DR74 | |

| TDK | SLF 7032 |

| EPCOS | B82462G |

10.2.1.2.4 Capacitor Selection

10.2.1.2.4.1 Input Capacitor

An input capacitor with a value of at least a 10 µF is recommended to improve transient behavior of the regulator and EMI behavior of the total power supply circuit. A ceramic capacitor or a tantalum capacitor with a 100-nF ceramic capacitor in parallel, placed close to the IC, is recommended.

10.2.1.2.4.2 Output Capacitor DC-DC Converter

The major parameter necessary to define the output capacitor is the maximum allowed output voltage ripple of the converter. This ripple is determined by two parameters of the capacitor, the capacitance and the ESR. Calclating the minimum capacitance required to define the ripple is possible, supposing that the ESR is zero, by using Equation 7:

Parameter ƒ is the switching frequency and ΔV is the maximum allowed ripple.

With a chosen ripple voltage of 10 mV, a minimum capacitance of 22 µF is needed. The total ripple is larger due to the ESR of the output capacitor. This additional component of the ripple can be calculated using Equation 8:

An additional ripple of 20 mV is the result of using a tantalum capacitor with a low ESR of 80 mΩ. The total ripple is the sum of the ripple caused by the capacitance and the ripple caused by the ESR of the capacitor. In this example, the total ripple is 30 mV. Additional ripple is caused by load transients. This means that the output capacitance needs to be larger than calculated above to meet the total ripple requirements. The output capacitor has to completely supply the load during the charging phase of the inductor. A reasonable value of the output capacitance depends on the speed of the load transients and the load current during the load change. In typical applications a 100 µF capacitance is recommended. For economical reasons this usually is a tantalum capacitor. Because of this the control loop has been optimized for using output capacitors with an ESR of above 30 mΩ. The minimum value for the output capacitor is 22 µF.

10.2.1.2.4.2.1 Small Signal Stability

When using output capacitors with lower ESR, like ceramics, it is recommended to use the adjustable voltage version. The missing ESR can be easily compensated there in the feedback divider. Typically a capacitor in the range of 10 pF in parallel with R3 helps to obtain small signal stability, with the lowest ESR output capacitors. For more detailed analysis the small signal transfer function of the error amplifier and regulator, which is given in Equation 9, can be used.

10.2.1.2.4.3 Output Capacitor LDO

To ensure stable output regulation, it is required to use an output capacitor at the LDO output. Ceramic capacitors in the range from 1 µF up to 4.7 µF is recommended. Using the standard ESR tantalum is recommended at capacitance of 4.7 µF and above. There is no maximum capacitance value.

10.2.1.3 Application Curves

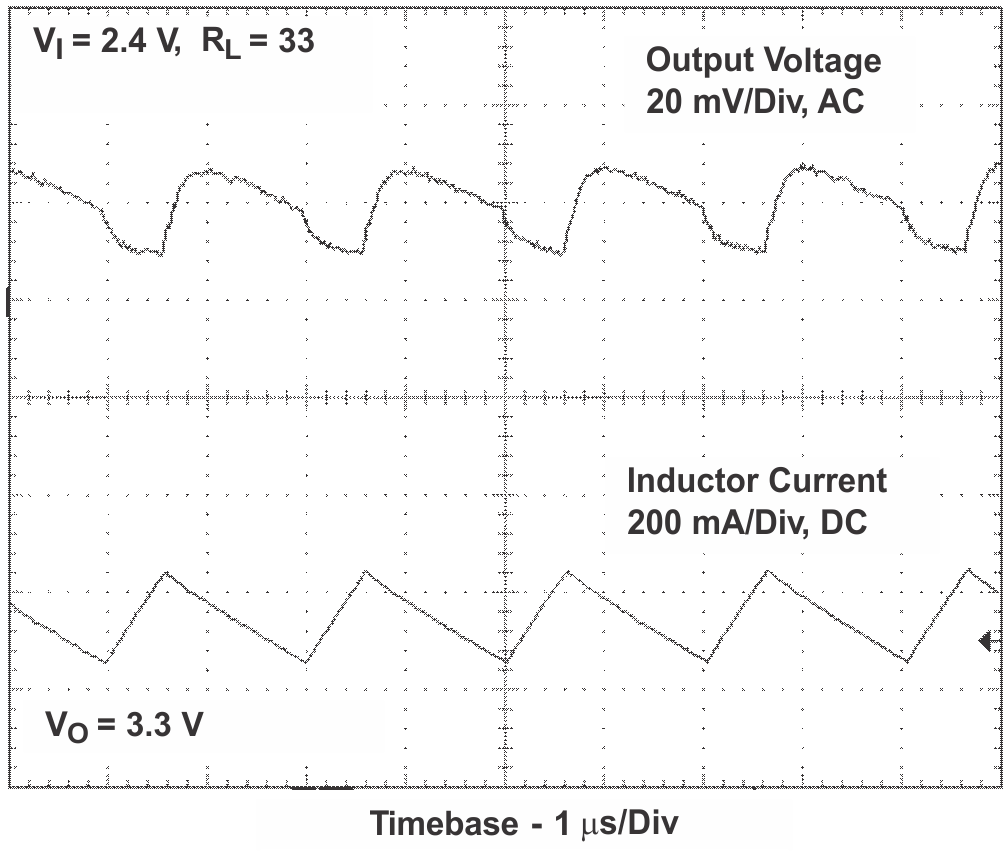

Figure 19. TPS61121 Boost Converter Output Voltage in Continuous Mode

Figure 19. TPS61121 Boost Converter Output Voltage in Continuous Mode

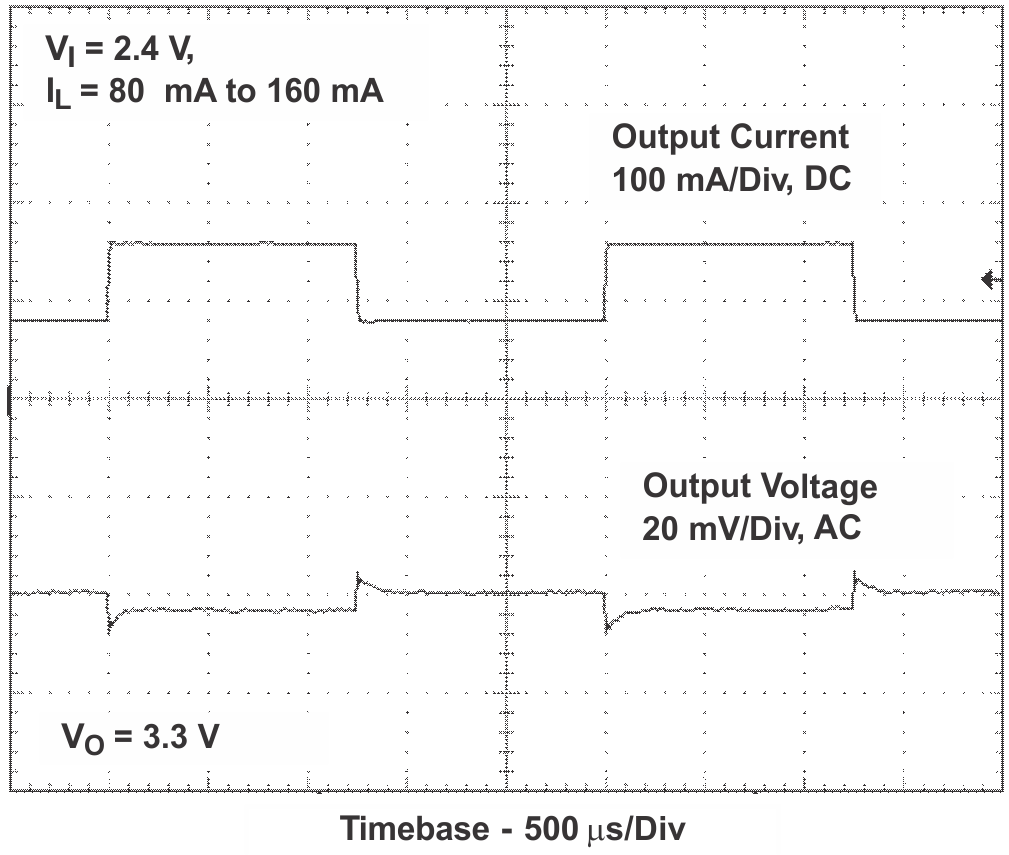

Figure 21. TPS61121 Boost Converter Load Transient Response

Figure 21. TPS61121 Boost Converter Load Transient Response

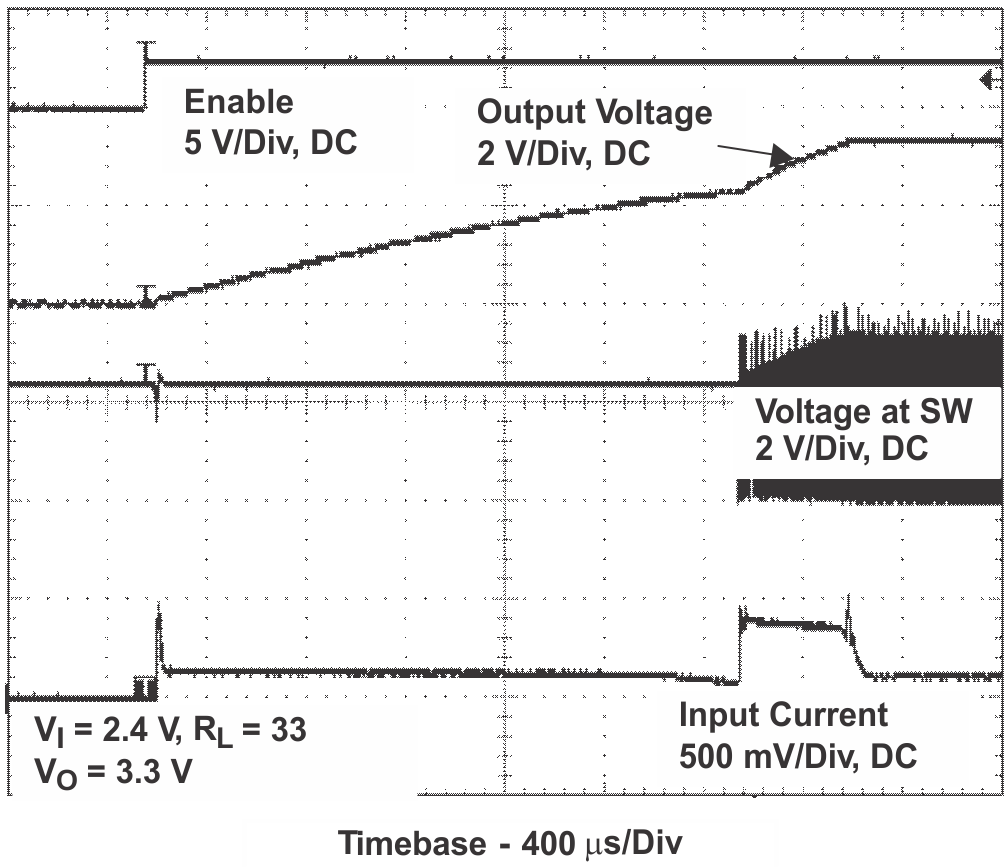

Figure 23. TPS61121 Boost Converter Start-up After Enable

Figure 23. TPS61121 Boost Converter Start-up After Enable

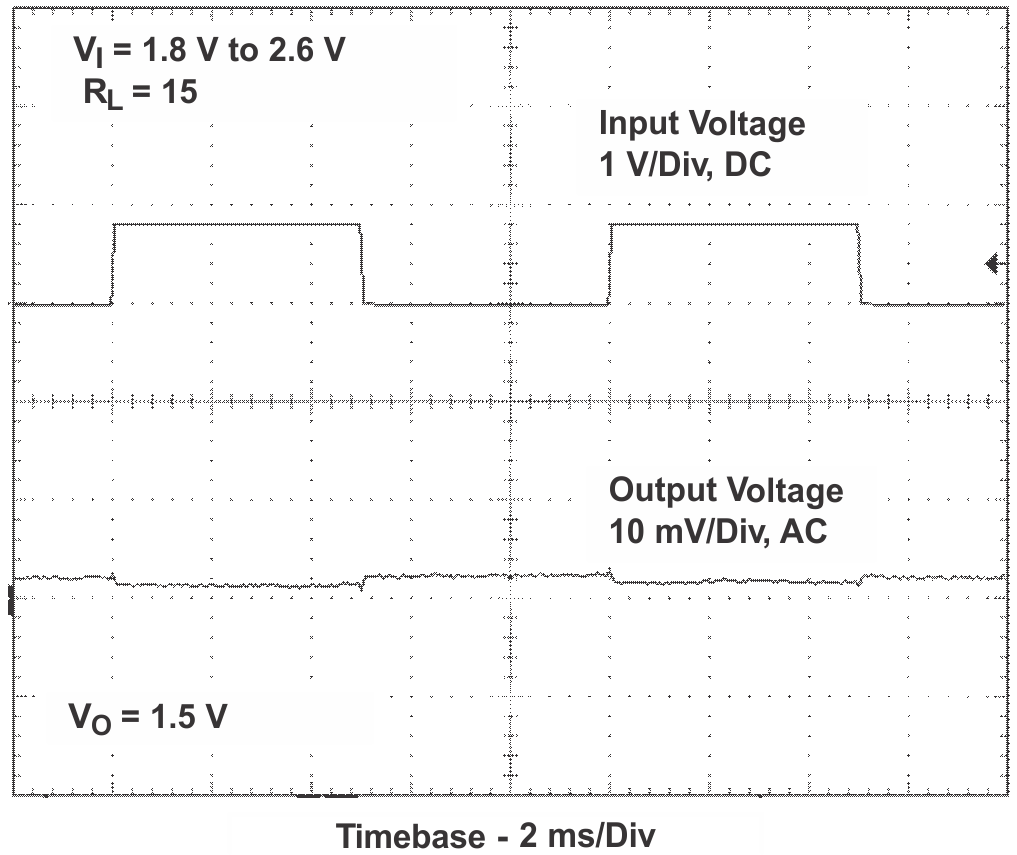

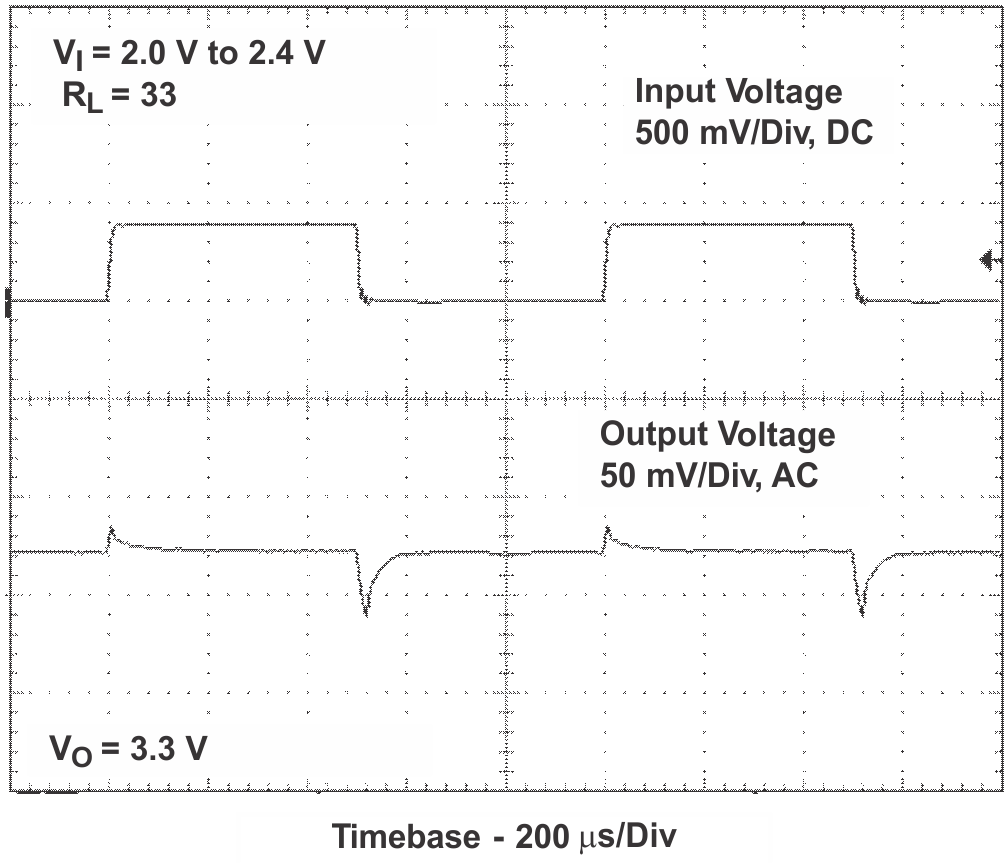

Figure 25. TPS61121 LDO Line Transient Response

Figure 25. TPS61121 LDO Line Transient Response

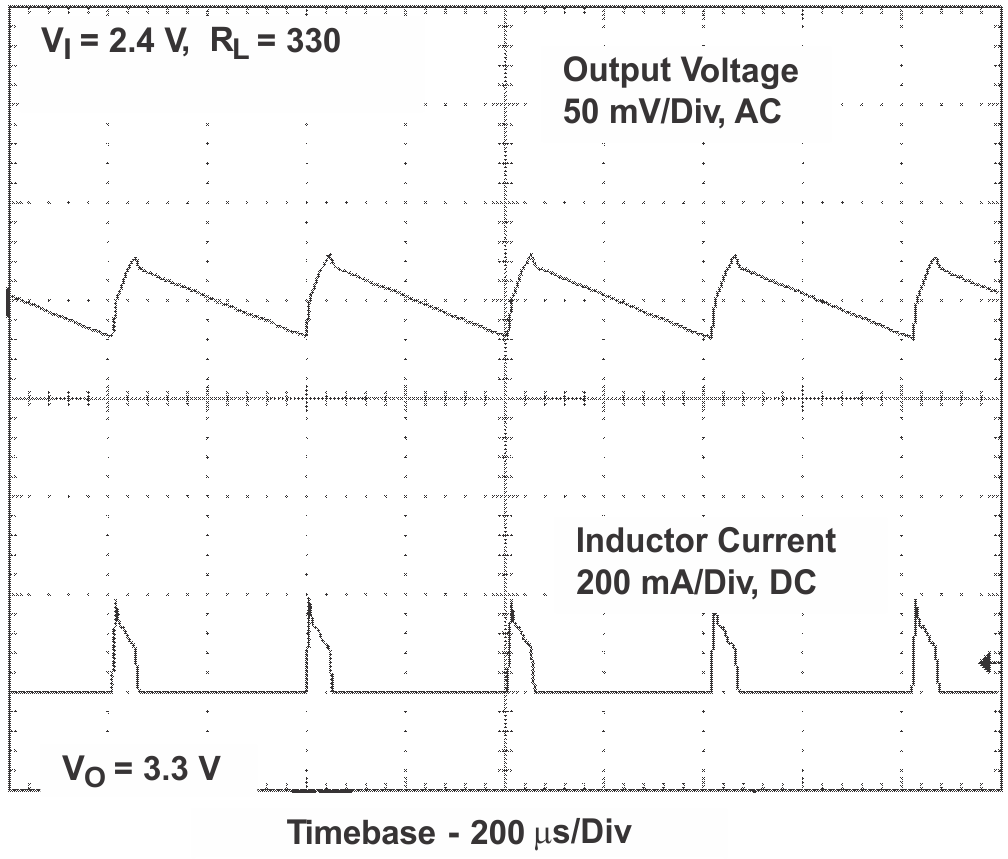

Figure 20. TPS61121 Boost Converter Output Voltage in Power Save Mode

Figure 20. TPS61121 Boost Converter Output Voltage in Power Save Mode

Figure 22. TPS61121 Boost Converter Line Transient Response

Figure 22. TPS61121 Boost Converter Line Transient Response

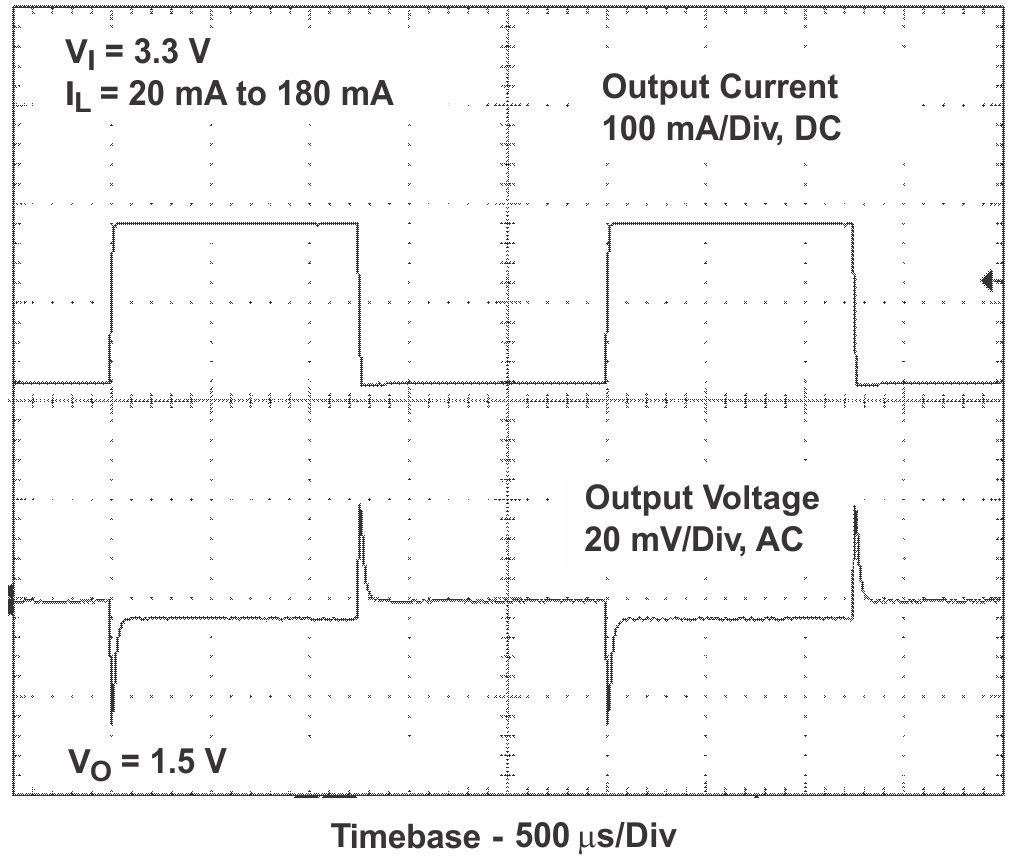

Figure 24. TPS61121 LDO Load Transient Response

Figure 24. TPS61121 LDO Load Transient Response

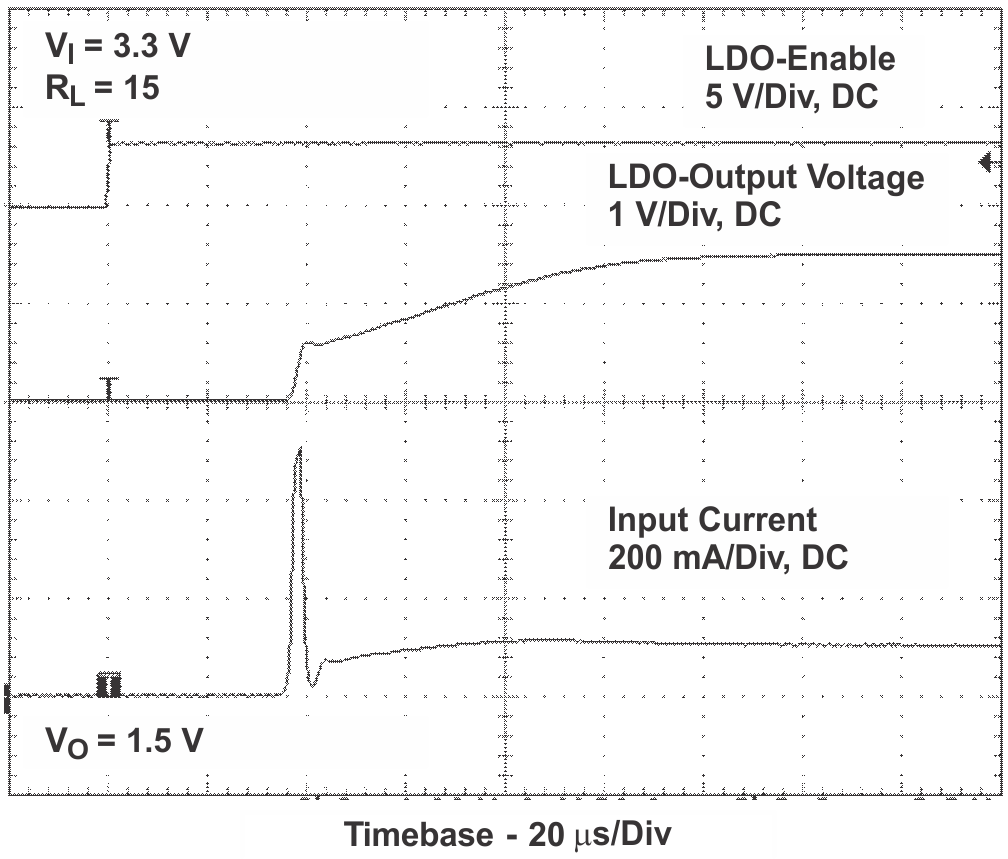

Figure 26. TPS61121 LDO Start-up After Enable

Figure 26. TPS61121 LDO Start-up After Enable

10.2.2 Low Profile Solution, Maximum Height 1.8 mm

The TPS6112x boost converter with LDO features two independent output voltages. An efficient synchronous boost converter provides a 3.3-V VOUT1 with output currents up to 500 mA. A 200-mA LDO regulator generates a 1.5-V VOUT2. The two outputs can be used independently from each other. TPS6112x supports the lower profile of inductor with maximum height 1.8 mm.

Figure 27. Low Profile Solution, Maximum Height 1.8 mm

Figure 27. Low Profile Solution, Maximum Height 1.8 mm

10.2.3 Dual Power Supply With Auxiliary Positive Output Voltage

The TPS6112x boost converter with LDO features multiple output voltages. An efficient synchronous boost converter provides Vout1 3.3 V with output currents up to 500mA. A 200-mA LDO regulator generates Vout2 1.5 V. Another rail provides 6 V with discrete charge pump added.

Figure 28. Dual Power Supply With Auxiliary Positive Output Voltage

Figure 28. Dual Power Supply With Auxiliary Positive Output Voltage

10.2.4 Dual Power Supply With Auxiliary Negative Output Voltage

The TPS6112x boost converter with LDO features multiple output voltages. An efficient synchronous boost converter provides Vout1 3.3 V with output currents up to 500 mA. A 200-mA LDO regulator generates Vout2 1.5 V. Another rail provides –3 V with discrete charge pump added.

Figure 29. Dual Power Supply With Auxiliary Negative Output Voltage

Figure 29. Dual Power Supply With Auxiliary Negative Output Voltage

10.2.5 Single Output Using LDO as Filter

The TPS6112x could provide a linear output of 3.3 V with the input from the output of the boost converter, and deliver 200-mA output current.

Figure 30. Single Output Using LDO as Filter

Figure 30. Single Output Using LDO as Filter

10.2.6 Dual Input Power Supply Solution

The TPS6112x boost converter can support dual input power supply, one input for boost converter to generate a 3.3 Vout with 500-mA output current, while the other input for LDO to generate the second 3.3 Vout with 200-mA output current.

Figure 31. Dual Input Power Supply Solution

Figure 31. Dual Input Power Supply Solution