JAJS711X July 2000 – June 2017 LM3478

PRODUCTION DATA.

- 1 特長

- 2 アプリケーション

- 3 説明

- 4 改訂履歴

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Applications

- 8.2.1

Typical High Efficiency Step-Up (Boost) Converter

- 8.2.1.1 Design Requirements

- 8.2.1.2

Detailed Design Procedure

- 8.2.1.2.1 Custom Design with WEBENCH Tools

- 8.2.1.2.2 Power Inductor Selection

- 8.2.1.2.3 Programming the Output Voltage

- 8.2.1.2.4 Setting the Current Limit

- 8.2.1.2.5 Current Limit with External Slope Compensation

- 8.2.1.2.6 Power Diode Selection

- 8.2.1.2.7 Power MOSFET Selection

- 8.2.1.2.8 Input Capacitor Selection

- 8.2.1.2.9 Output Capacitor Selection

- 8.2.1.2.10 Compensation

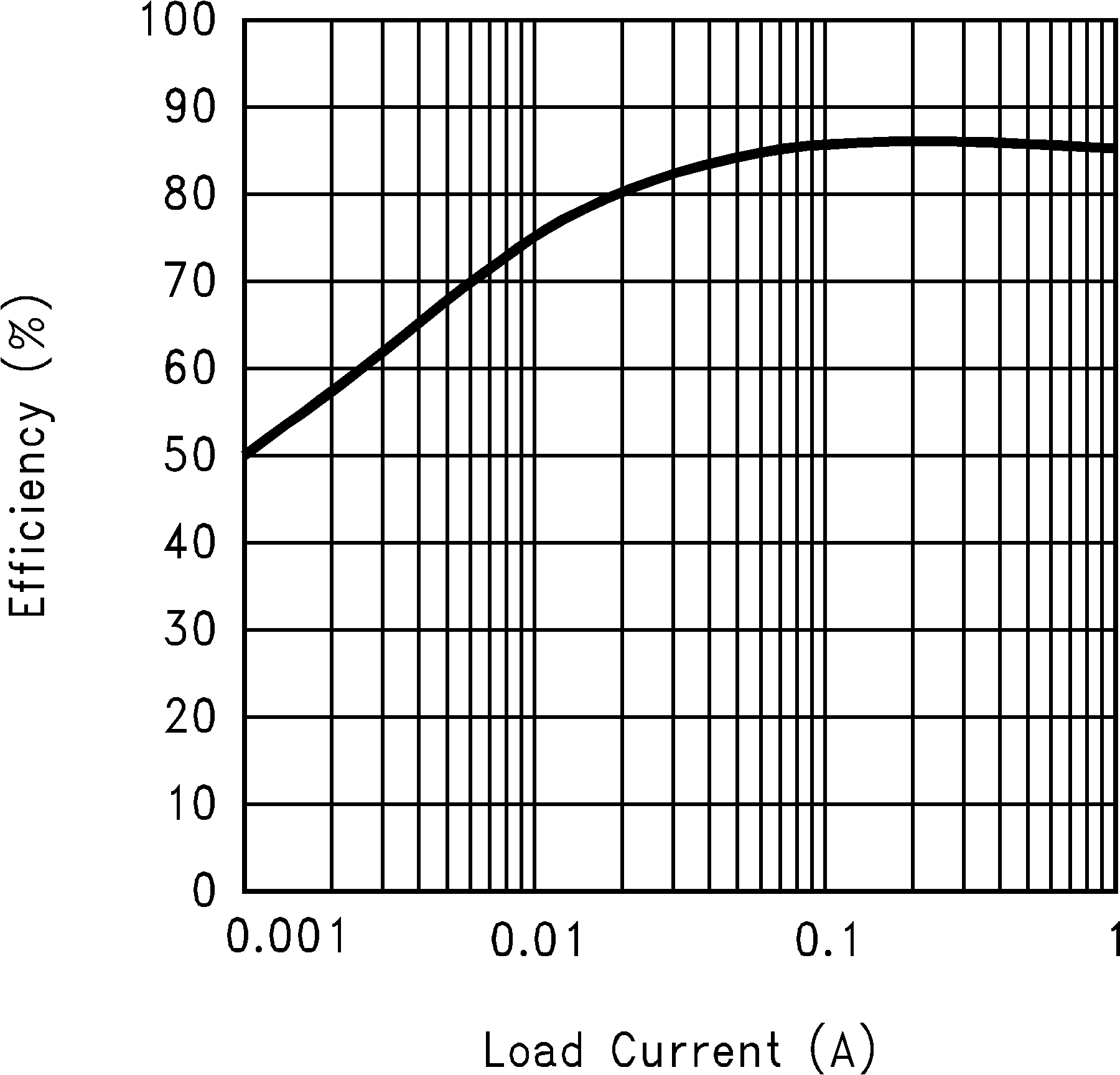

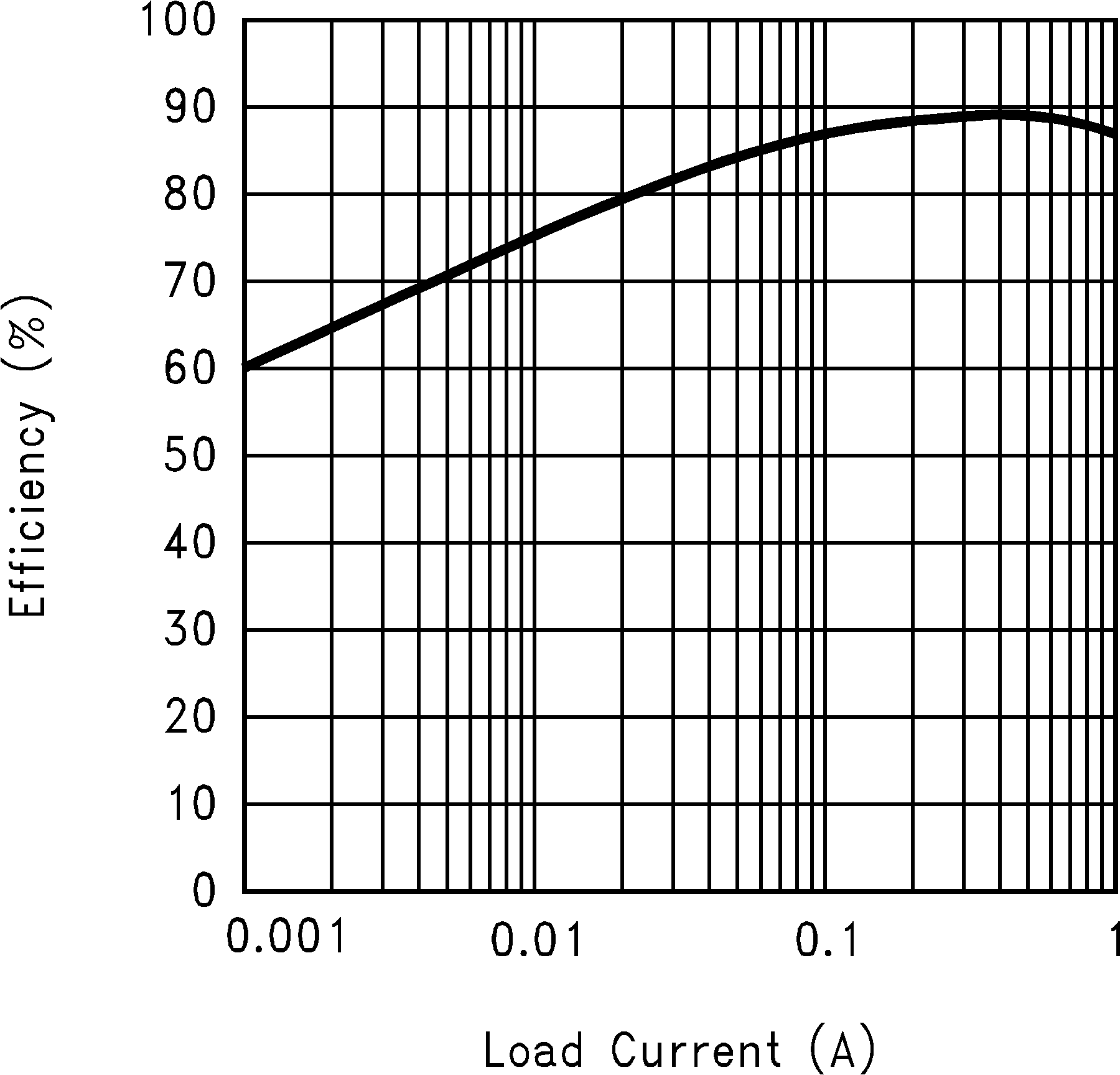

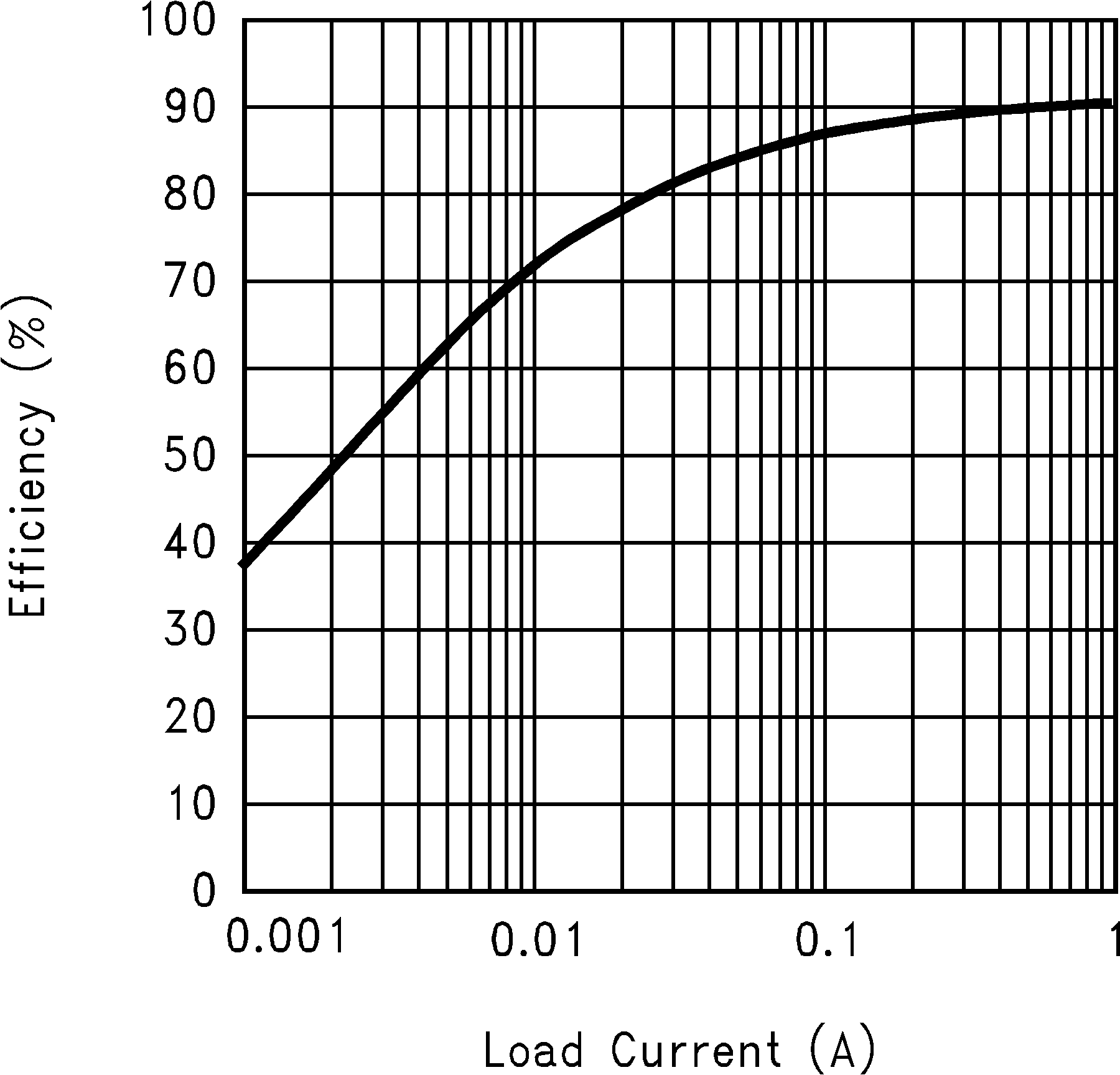

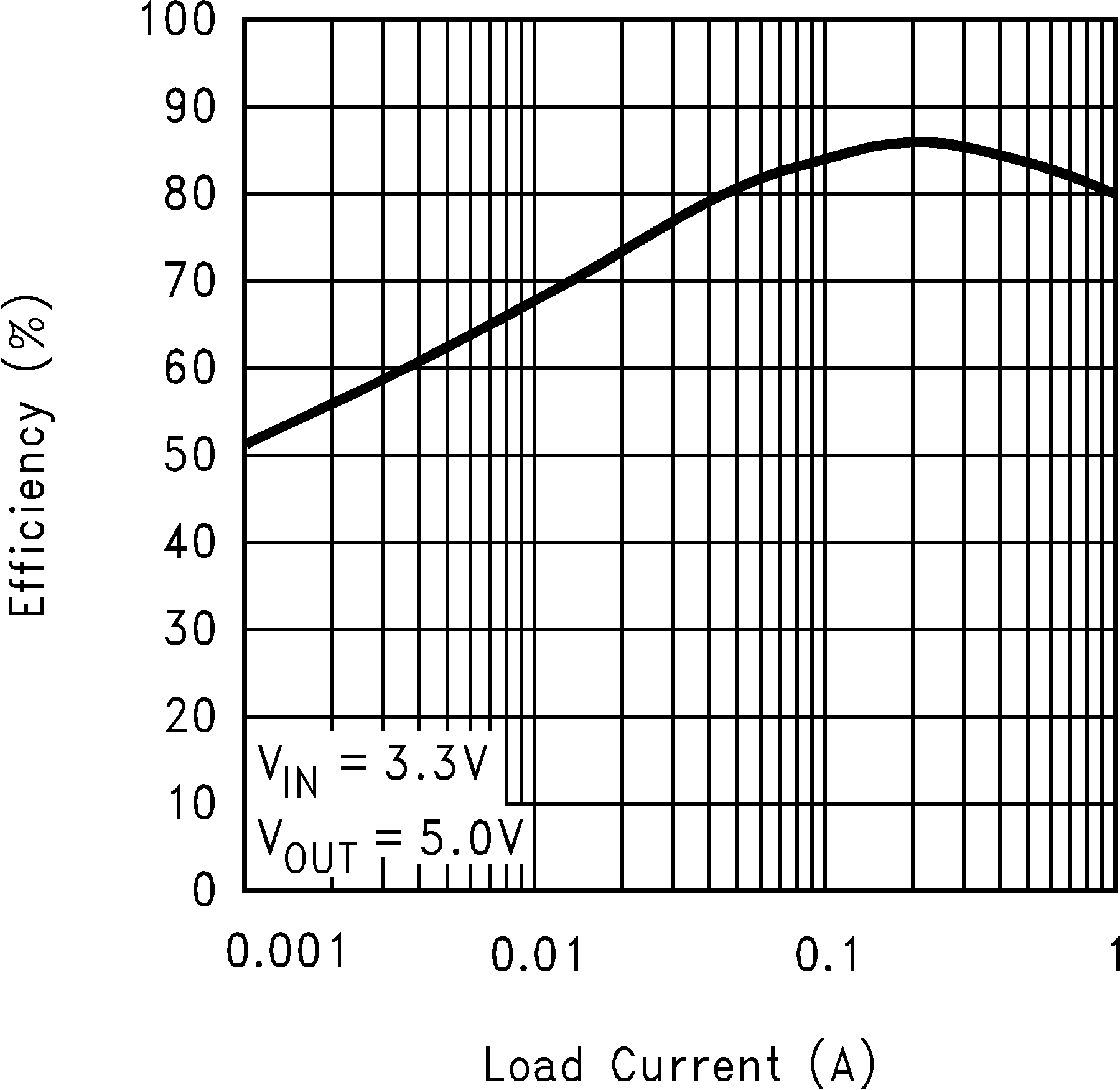

- 8.2.1.3 Application Curves

- 8.2.2 Typical SEPIC Converter

- 8.2.1

Typical High Efficiency Step-Up (Boost) Converter

- 9 Power Supply Recommendations

- 10Layout

- 11デバイスおよびドキュメントのサポート

- 12メカニカル、パッケージ、および注文情報

パッケージ・オプション

メカニカル・データ(パッケージ|ピン)

サーマルパッド・メカニカル・データ

発注情報

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LM3478 may be operated in either the continuous conduction mode (CCM) or the discontinuous current conduction mode (DCM). The following applications are designed for the CCM operation. This mode of operation has higher efficiency and usually lower EMI characteristics than the DCM.

8.2 Typical Applications

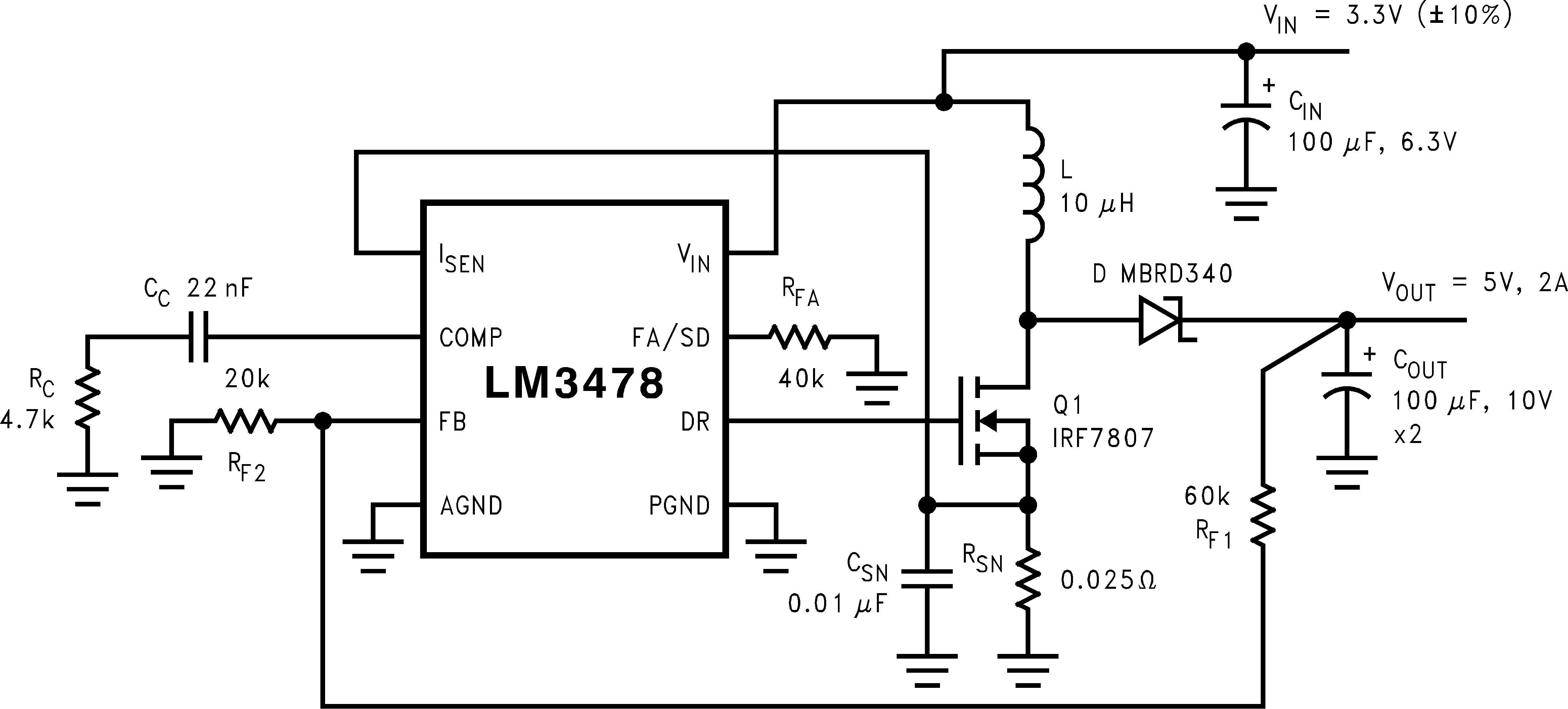

8.2.1 Typical High Efficiency Step-Up (Boost) Converter

Figure 27. Typical High Efficiency Step-Up (Boost) Converter Schematic

Figure 27. Typical High Efficiency Step-Up (Boost) Converter Schematic

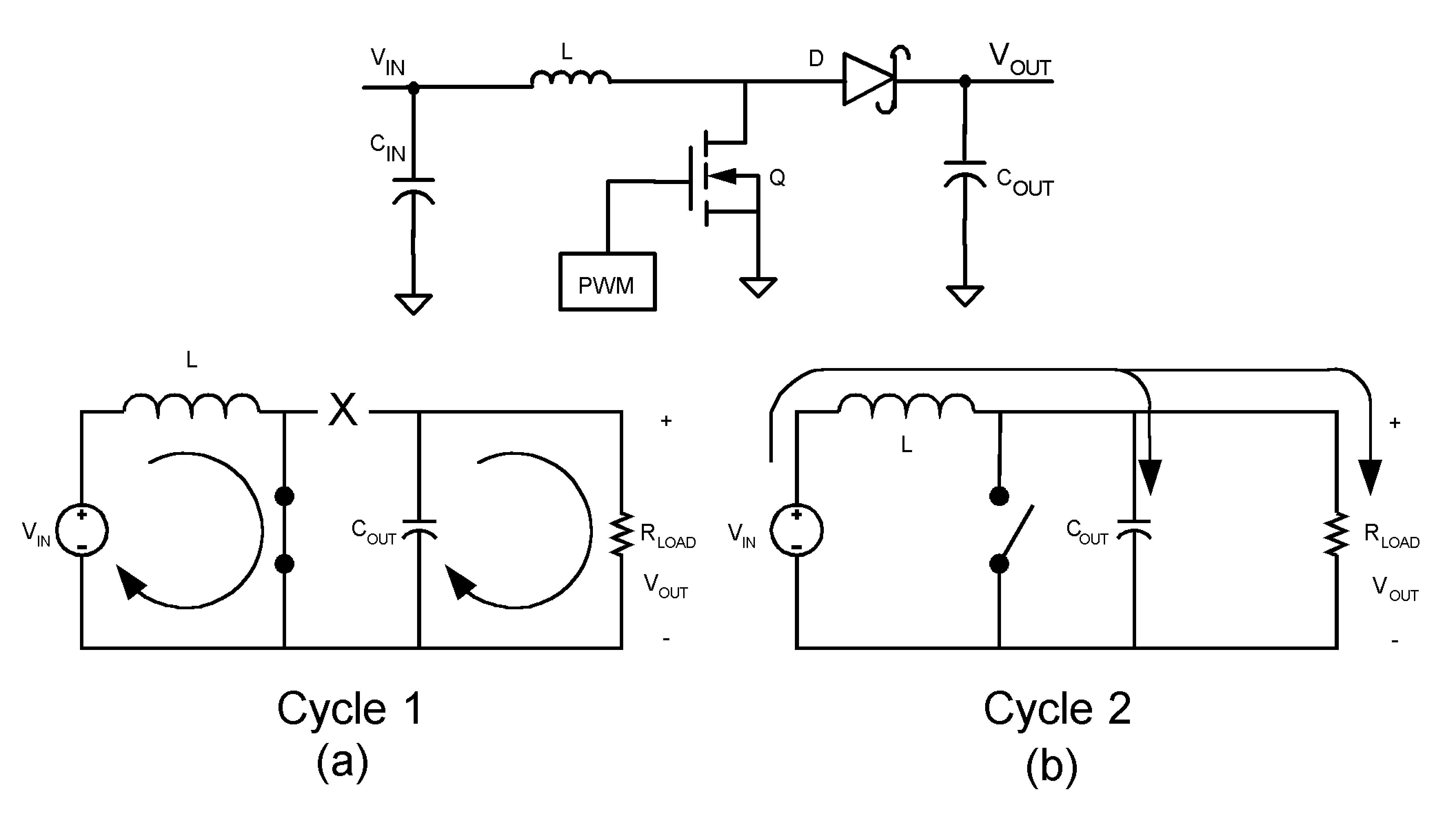

The boost converter converts a low input voltage into a higher output voltage. The basic configuration for a boost converter is shown in Figure 28. In the CCM (when the inductor current never reaches zero at steady state), the boost regulator operates in two states. In the first state of operation, MOSFET Q is turned on and energy is stored in the inductor. During this state, diode D is reverse biased and load current is supplied by the output capacitor, COUT.

In the second state, MOSFET Q is off and the diode is forward biased. The energy stored in the inductor is transferred to the load and the output capacitor. The ratio of the switch on time to the total period is the duty cycle D as shown in Equation 8.

Including the voltage drop across the MOSFET and the diode the definition for the duty cycle is shown in Equation 9.

Vd is the forward voltage drop of the diode and Vq is the voltage drop across the MOSFET when it is on.

8.2.1.1 Design Requirements

To properly size the components for the application, the designer needs the following parameters: input voltage range, output voltage, output current range, and required switching frequency. These four main parameters affect the choices of component available to achieve a proper system behavior.

For the power supply, the input impedance of the supply rail should be low enough that the input current transient does not drop below the UVLO value. The factors determining the choice of inductor used should be the average inductor current, and the inductor current ripple. If the switching frequency is set high, the converter can be operated with very small inductor values. The maximum current that can be delivered to the load is set by the sense resistor, RSEN. Current limit occurs when the voltage generated across the sense resistor equals the current sense threshold voltage, VSENSE. Also, a resistor RSL adds additional slope compensation, if required.

The following sections describe the design requirements for a typical LM3478 boost application.

8.2.1.2 Detailed Design Procedure

8.2.1.2.1 Custom Design with WEBENCH Tools

Click here to create a custom design using the LM3478 device with the WEBENCH® Power Designer.

- Start by entering your VIN, VOUT and IOUT requirements.

- Optimize your design for key parameters like efficiency, footprint and cost using the optimizer dial and compare this design with other possible solutions from Texas Instruments.

- WEBENCH Power Designer provides you with a customized schematic along with a list of materials with real time pricing and component availability.

- In most cases, you will also be able to:

- Run electrical simulations to see important waveforms and circuit performance,

- Run thermal simulations to understand the thermal performance of your board,

- Export your customized schematic and layout into popular CAD formats,

- Print PDF reports for the design, and share your design with colleagues.

- Get more information about WEBENCH tools at www.ti.com/webench.

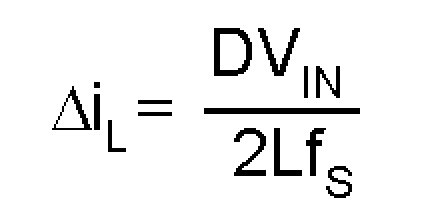

8.2.1.2.2 Power Inductor Selection

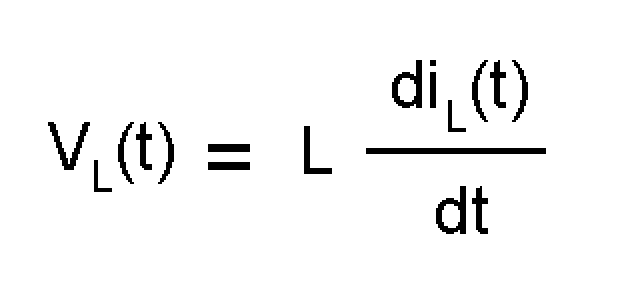

The inductor is one of the two energy storage elements in a boost converter. Figure 29 shows how the inductor current varies during a switching cycle. The current through an inductor is quantified using Equation 10, which shows the relationship of L, IL and VL.

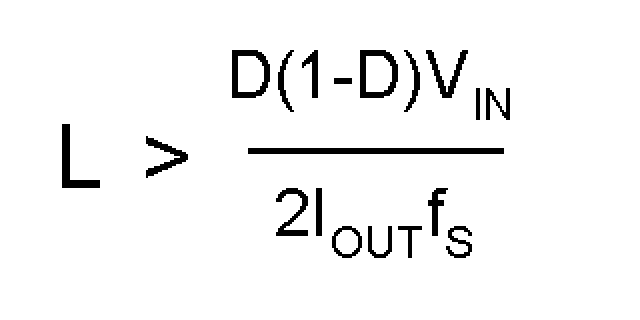

The important quantities in determining a proper inductance value are IL (the average inductor current) and ΔIL (the inductor current ripple). If ΔIL is larger than IL, the inductor current will drop to zero for a portion of the cycle and the converter will operate in the DCM. All the analysis in this datasheet assumes operation in the CCM. To operate in the CCM, the following condition must be met by using Equation 11.

Choose the minimum IOUT to determine the minimum inductance value. A common choice is to set ΔIL to 30% of IL. Choosing an appropriate core size for the inductor involves calculating the average and peak currents expected through the inductor. Use Equation 12, Equation 13, and Equation 14 to the peak inductor current in a boost converter.

An inductor size with ratings higher than these values has to be selected. If the inductor is not properly rated, saturation will occur and may cause the circuit to malfunction.

The LM3478 can be set to switch at very high frequencies. When the switching frequency is high, the converter can be operated with very small inductor values. The LM3478 senses the peak current through the switch which is the same as the peak inductor current as calculated in the previous equation.

Figure 29. Inductor Current and Diode Current

Figure 29. Inductor Current and Diode Current

8.2.1.2.3 Programming the Output Voltage

The output voltage can be programmed using a resistor divider between the output and the FB pin. The resistors are selected such that the voltage at the FB pin is 1.26 V. Pick RF1 (the resistor between the output voltage and the feedback pin) and RF2 (the resistor between the feedback pin and ground) can be selected using the following equation,

A 100-pF capacitor may be connected between the feedback and ground pins to reduce noise.

8.2.1.2.4 Setting the Current Limit

The maximum amount of current that can be delivered to the load is set by the sense resistor, RSEN. Current limit occurs when the voltage that is generated across the sense resistor equals the current sense threshold voltage, VSENSE. When this threshold is reached, the switch will be turned off until the next cycle. Limits for VSENSE are specified in the electrical characteristics section. VSENSE represents the maximum value of the internal control signal VCS as shown in Figure 30. This control signal, however, is not a constant value and changes over the course of a period as a result of the internal compensation ramp (VSL). Therefore the current limit threshold will also change. The actual current limit threshold is a function of the sense voltage (VSENSE) and the internal compensation ramp:

Where ISWLIMIT is the peak switch current limit, defined by Equation 17.

Figure 30. Current Sense Voltage vs Duty Cycle

Figure 30. Current Sense Voltage vs Duty Cycle

Figure 30 shows how VCS (and current limit threshold voltage) change with duty cycle. The curve is equivalent to the internal compensation ramp slope (Se) and is bounded at low duty cycle by VSENSE, shown as a dotted line. As duty cycle increases, the control voltage is reduced as VSL ramps up. The graph also shows the short circuit current limit threshold of 343 mV (typical) during the 325 ns (typical) blanking time. For higher frequencies this fixed blanking time obviously occupies more duty cycle, percentage wise. Since current limit threshold varies with duty cycle, the use Equation 17 to select RSEN and set the desired current limit threshold:

The numerator of Equation 17 is VCS, and ISWLIMIT using Equation 18.

To avoid false triggering, the current limit value should have some margin above the maximum operating value, typically 120%. Values for both VSENSE and VSL are specified in Electrical Characteristics. However, calculating with the limits of these two specs could result in an unrealistically wide current limit or RSEN range. Therefore, Equation 19 is recommended, using the VSL ratio value given in Electrical Characteristics.

RSEN is part of the current mode control loop and has some influence on control loop stability. Therefore, once the current limit threshold is set, loop stability must be verified. As described in the slope compensation section, Equation 20 must hold true for a current mode converter to be stable.

To verify that this equation holds true, use Equation 21.

If the selected RSEN is greater than this value, additional slope compensation must be added to ensure stability, as described in the section below.

8.2.1.2.5 Current Limit with External Slope Compensation

RSL is used to add additional slope compensation when required. It is not necessary in most designs and RSL should be no larger than necessary. Select RSL according to Equation 22.

Where RSEN is the selected value based on current limit. With RSL installed, the control signal includes additional external slope to stabilize the loop, which will also have an effect on the current limit threshold. Therefore, the current limit threshold must be re-verified, as illustrated in Equation 23, Equation 24, and Equation 25 below.

Where ΔVSL is the additional slope compensation generated as discussed in the slope compensation ramp section and calculated using Equation 24.

This changes the equation for current limit (or RSEN) as shown in Equation 25.

The RSEN and RSL values may have to be calculated iteratively in order to achieve both the desired current limit and stable operation. In some designs RSL can also help to filter noise on the ISEN pin.

If the inductor is selected such that ripple current is the recommended 30% value, and the current limit threshold is 120% of the maximum peak, a simpler method can be used to determine RSEN. Equation 26 below will provide optimum stability without RSL, provided that the above 2 conditions are met.

8.2.1.2.6 Power Diode Selection

Observation of the boost converter circuit shows that the average current through the diode is the average load current, and the peak current through the diode is the peak current through the inductor. The diode should be rated to handle more than its peak current. The peak diode current can be calculated using Equation 27.

Thermally the diode must be able to handle the maximum average current delivered to the output. The peak reverse voltage for boost converters is equal to the regulated output voltage. The diode must be capable of handling this voltage. To improve efficiency, a low forward drop schottky diode is recommended.

8.2.1.2.7 Power MOSFET Selection

The drive pin of the LM3478 must be connected to the gate of an external MOSFET. The drive pin (DR) voltage depends on the input voltage (see Typical Characteristics). In most applications, a logic level MOSFET can be used. For very low input voltages, a sub logic level MOSFET should be used. The selected MOSFET has a great influence on the system efficiency. The critical parameters for selecting a MOSFET are:

- Minimum threshold voltage, VTH(MIN)

- On-resistance, RDS(ON)

- Total gate charge, Qg

- Reverse transfer capacitance, CRSS

- Maximum drain to source voltage, VDS(MAX)

The off-state voltage of the MOSFET is approximately equal to the output voltage. Vds(max) must be greater than the output voltage. The power losses in the MOSFET can be categorized into conduction losses and switching losses. RDS(ON) is needed to estimate the conduction losses, Pcond:

The temperature effect on the RDS(ON) usually is quite significant. Assume 30% increase at hot.

For the current I in Equation 28 the average inductor current may be used.

Especially at high switching frequencies the switching losses may be the largest portion of the total losses.

The switching losses are very difficult to calculate due to changing parasitics of a given MOSFET in operation. Often the individual MOSFET's data sheet does not give enough information to yield a useful result. Equation 29 and Equation 30 give a rough idea how the switching losses are calculated:

8.2.1.2.8 Input Capacitor Selection

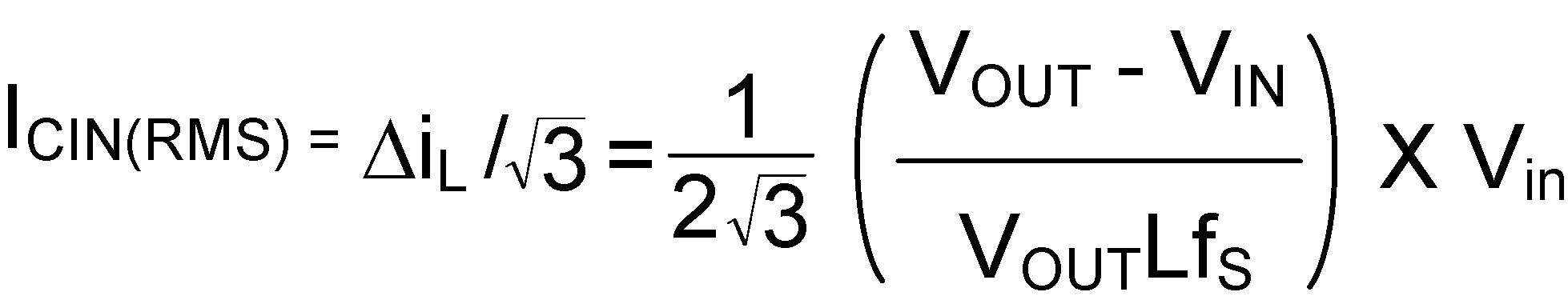

Due to the presence of an inductor at the input of a boost converter, the input current waveform is continuous and triangular as shown in Figure 29. The inductor ensures that the input capacitor sees fairly low ripple currents. However, as the input capacitor gets smaller, the input ripple goes up. The RMS current in the input capacitor is given using Equation 31.

The input capacitor should be capable of handling the RMS current. Although the input capacitor is not as critical in a boost application, low values can cause impedance interactions. Therefore a good quality capacitor should be chosen in the range of 10 µF to 20 µF. If a value lower than 10 µF is used, then problems with impedance interactions or switching noise can affect the LM3478. To improve performance, especially with Vin below 8 volts, it is recommended to use a 20 Ohm resistor at the input to provide an RC filter. The resistor is placed in series with the VIN pin with only a bypass capacitor attached to the VIN pin directly (see Figure 31). A 0.1-µF or 1-µF ceramic capacitor is necessary in this configuration. The bulk input capacitor and inductor will connect on the other side of the resistor at the input power supply.

Figure 31. Reducing IC Input Noise

Figure 31. Reducing IC Input Noise

8.2.1.2.9 Output Capacitor Selection

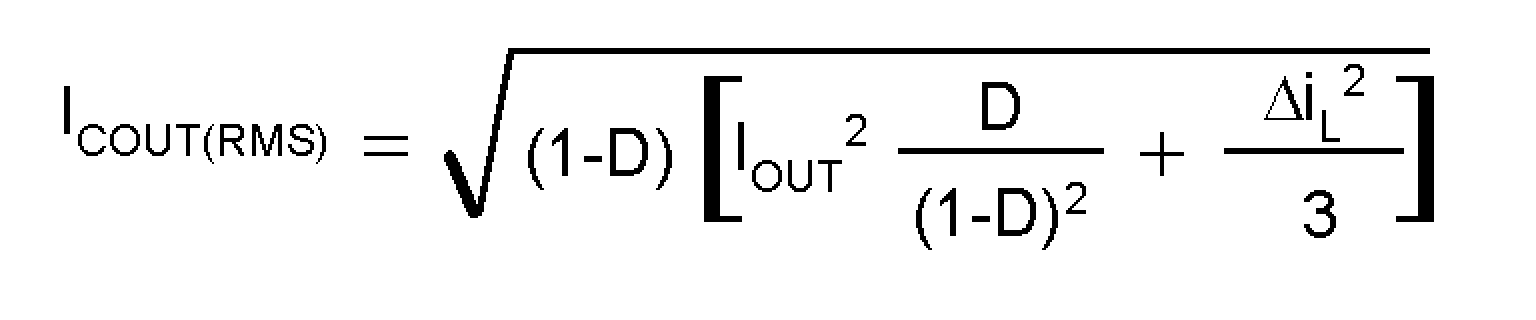

The output capacitor in a boost converter provides all the output current when the inductor is charging. As a result it sees very large ripple currents. The output capacitor should be capable of handling the maximum RMS current. Equation 32 shows the RMS current in the output capacitor.

Where

The ESR and ESL of the capacitor directly control the output ripple. Use capacitors with low ESR and ESL at the output for high efficiency and low ripple voltage. Surface mount tantalums, surface mount polymer electrolytic, polymer tantalum, or multi-layer ceramic capacitors are recommended at the output.

For applications that require very low output voltage ripple, a second stage LC filter often is a good solution. Most of the time it is lower cost to use a small second Inductor in the power path and an additional final output capacitor than to reduce the output voltage ripple by purely increasing the output capacitor without an additional LC filter.

8.2.1.2.10 Compensation

For detailed explanation on how to select the right compensation components to attach to the compensation pin for a boost topology, please see AN-1286 Compensation For The LM3748 Boost Controller SNVA067.

8.2.1.3 Application Curves

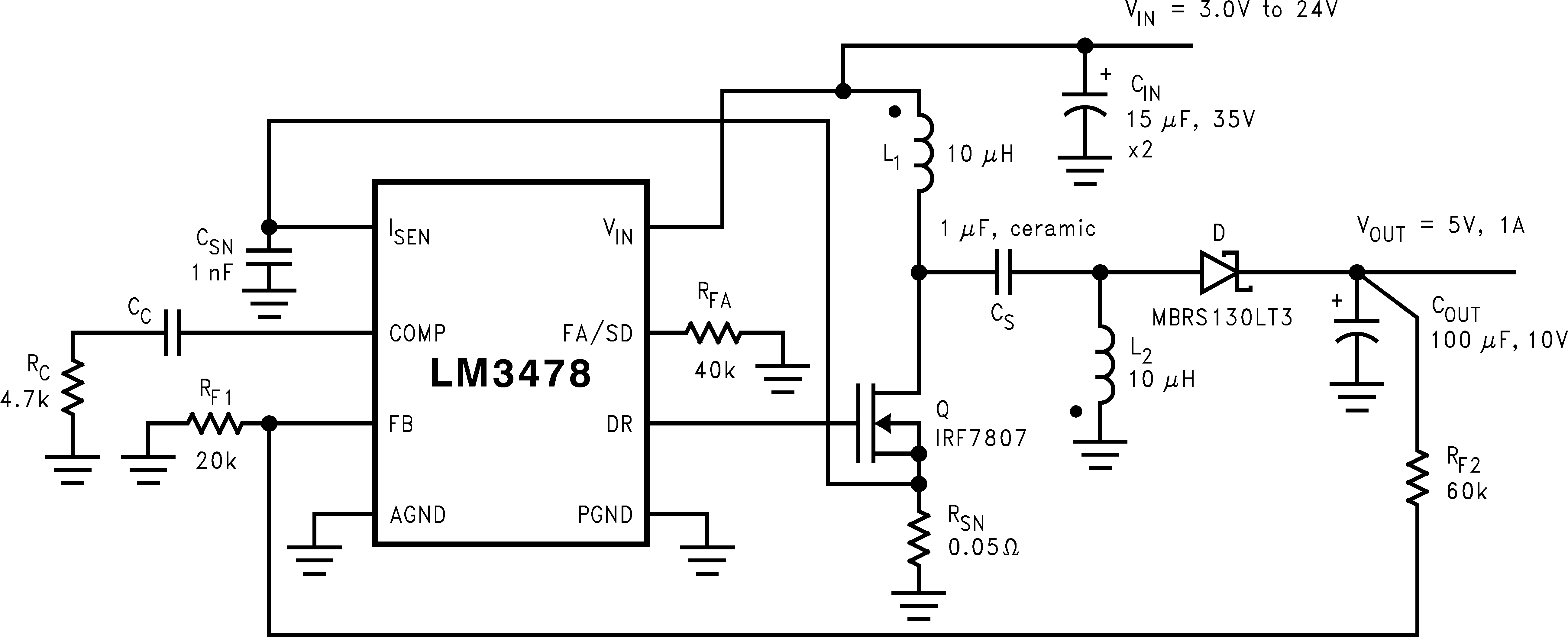

8.2.2 Typical SEPIC Converter

Figure 34. Typical SEPIC Converter

Figure 34. Typical SEPIC Converter

Since the LM3478 controls a low-side N-Channel MOSFET, it can also be used in SEPIC (Single Ended Primary Inductance Converter) applications. An example of a SEPIC using the LM3478 is shown in Figure 34. Note that the output voltage can be higher or lower than the input voltage. The SEPIC uses two inductors to step-up or step-down the input voltage. The inductors L1 and L2 can be two discrete inductors or two windings of a coupled inductor since equal voltages are applied across the inductor throughout the switching cycle. Using two discrete inductors allows use of catalog magnetics, as opposed to a custom inductor. The input ripple can be reduced along with size by using the coupled windings for L1 and L2.

Due to the presence of the inductor L1 at the input, the SEPIC inherits all the benefits of a boost converter. One main advantage of a SEPIC over a boost converter is the inherent input to output isolation. The capacitor CS isolates the input from the output and provides protection against a shorted or malfunctioning load. Hence, the SEPIC is useful for replacing boost circuits when true shutdown is required. This means that the output voltage falls to 0V when the switch is turned off. In a boost converter, the output can only fall to the input voltage minus a diode drop.

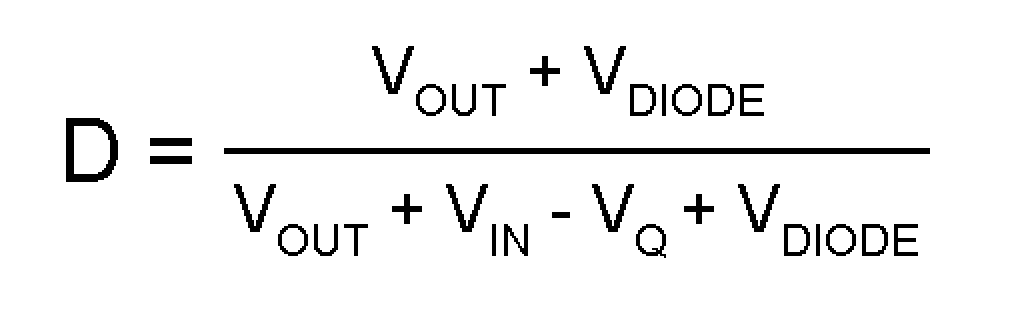

The duty cycle of a SEPIC is given using Equation 34.

In Equation 34, VQ is the on-state voltage of the MOSFET, Q, and VDIODE is the forward voltage drop of the diode.

8.2.2.1 Design Requirements

To properly size the components for the application, the designer needs the following parameters: input voltage range, output voltage, output current range, and required switching frequency. These four main parameters affect the choices of component available to achieve a proper system behavior.

For the power supply, the input impedance of the supply rail should be low enough that the input current transient does not drop below the UVLO value. The factors determining the choice of inductor used should be the average inductor current, and the inductor current ripple. If the switching frequency is set high, the converter can be operated with very small inductor values. The maximum current that can be delivered to the load is set by the sense resistor, RSEN. Current limit occurs when the voltage generated across the sense resistor equals the current sense threshold voltage, VSENSE. Also, a resistor RSL adds additional slope compensation, if required.

The following sections describe the design requirements for a typical LM3478 boost application.

8.2.2.2 Detailed Design Procedure

8.2.2.2.1 Power MOSFET Selection

As in a boost converter, parameters governing the selection of the MOSFET are the minimum threshold voltage, VTH(MIN), the on-resistance, RDS(ON), the total gate charge, Qg, the reverse transfer capacitance, CRSS, and the maximum drain to source voltage, VDS(MAX). The peak switch voltage in a SEPIC is given using Equation 35.

The selected MOSFET should satisfy the condition:

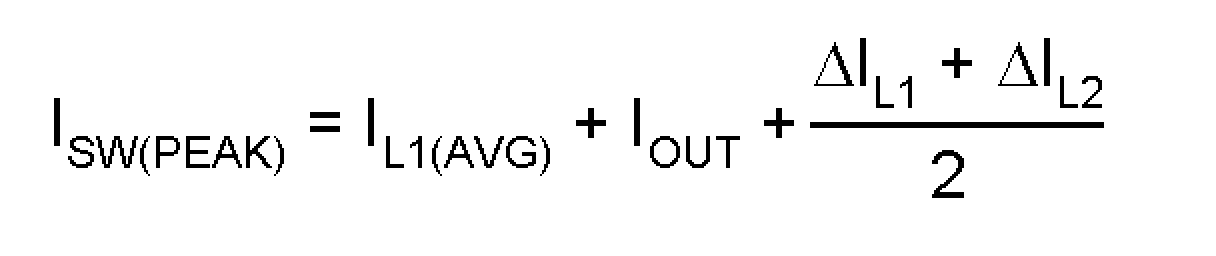

The peak switch current is given using Equation 37.

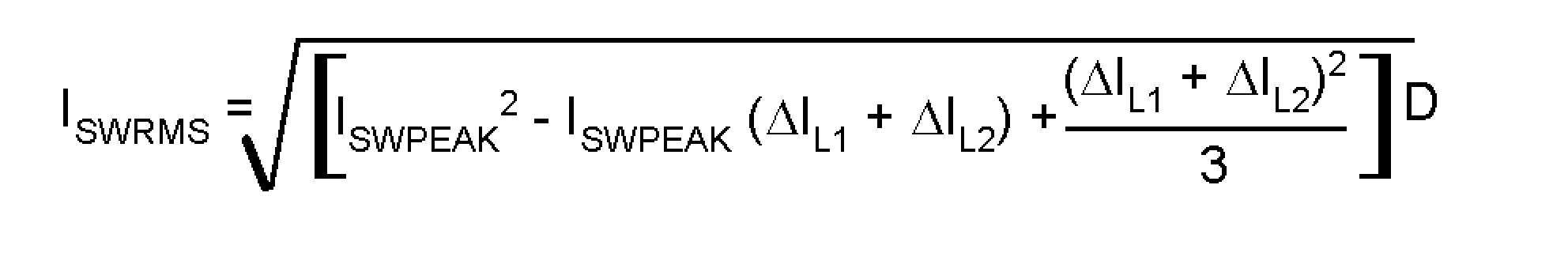

The RMS current through the switch is given using Equation 38.

8.2.2.2.2 Power Diode Selection

The Power diode must be selected to handle the peak current and the peak reverse voltage. In a SEPIC, the diode peak current is the same as the switch peak current. The off-state voltage or peak reverse voltage of the diode is VIN + VOUT. Similar to the boost converter, the average diode current is equal to the output current. Schottky diodes are recommended.

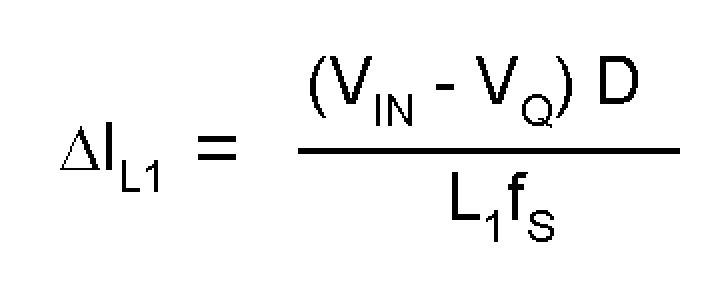

8.2.2.2.3 Selection of Inductors L1 and L2

Proper selection of inductors L1 and L2 to maintain continuous current conduction mode requires calculations of the following parameters.

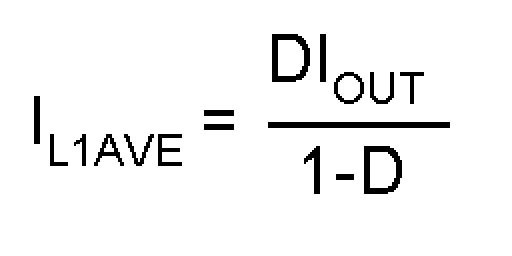

Average current in the inductors can be calculated using Equation 39.

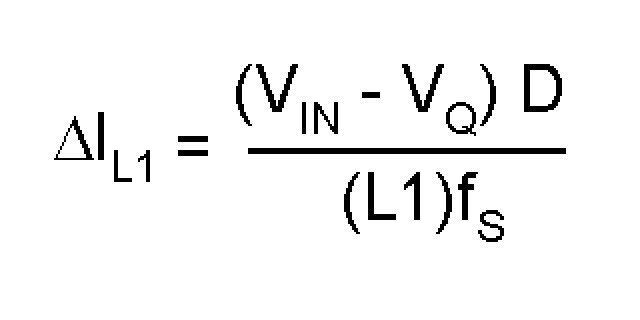

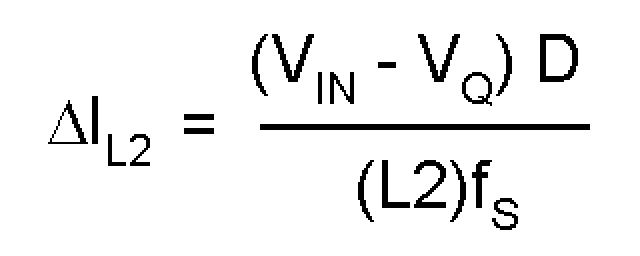

Peak to peak ripple current, to calculate core loss if necessary using Equation 41 and Equation 42.

Maintaining the condition IL > ΔiL/2 to ensure continuous current conduction yields Equation 43 and Equation 44.

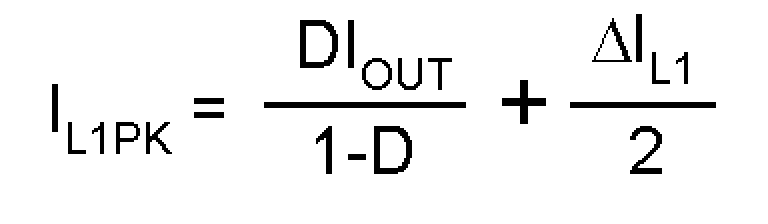

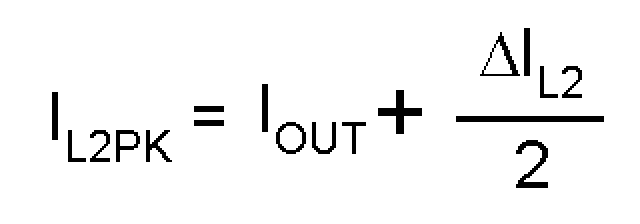

Peak current in the inductor, use Equation 45 and Equation 46 to ensure the inductor does not saturate.

IL1PK must be lower than the maximum current rating set by the current sense resistor.

The value of L1 can be increased above the minimum recommended to reduce input ripple and output ripple. However, once DIL1 is less than 20% of IL1AVE, the benefit to output ripple is minimal.

By increasing the value of L2 above the minimum recommended, ΔIL2 can be reduced, which in turn will reduce the output ripple voltage:

where ESR is the effective series resistance of the output capacitor.

If L1 and L2 are wound on the same core, then L1 = L2 = L. All of the previous equations will hold true if the inductance is replaced by 2L.

8.2.2.2.4 Sense Resistor Selection

The peak current through the switch, ISW(PEAK) can be adjusted using the current sense resistor, RSEN, to provide a certain output current. Resistor RSEN can be selected using Equation 48

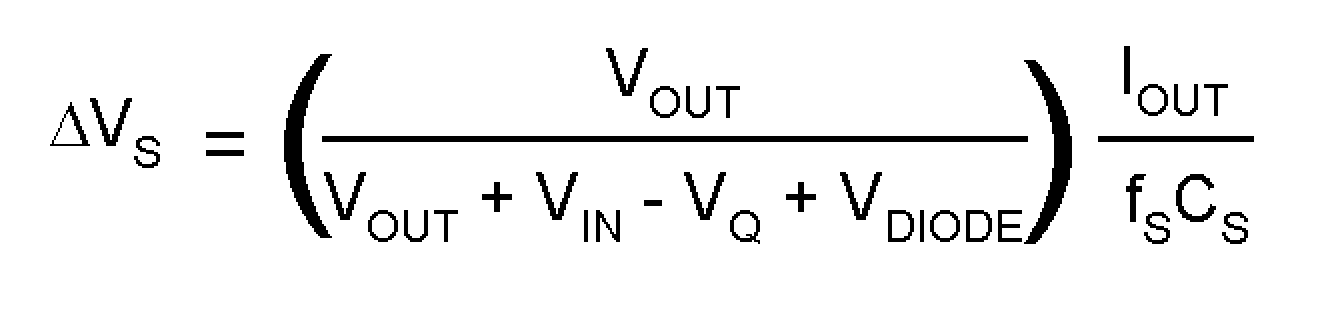

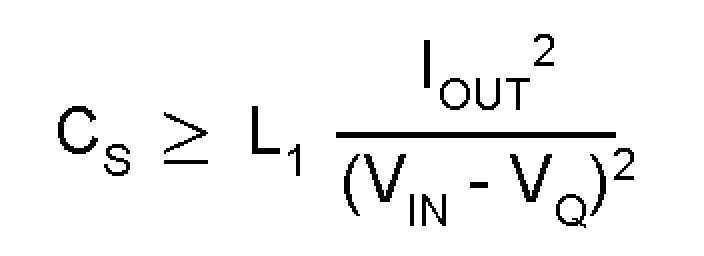

8.2.2.2.5 Sepic Capacitor Selection

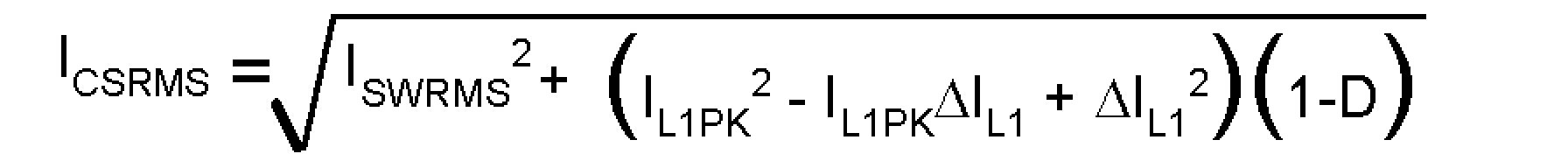

The selection of the SEPIC capacitor, CS, depends on the RMS current. The RMS current of the SEPIC capacitor is given by Equation 49.

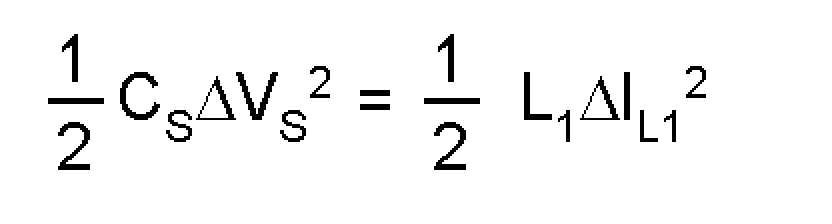

The SEPIC capacitor must be rated for a large ACrms current relative to the output power. This property makes the SEPIC much better suited to lower power applications where the RMS current through the capacitor is relatively small (relative to capacitor technology). The voltage rating of the SEPIC capacitor must be greater than the maximum input voltage. There is an energy balance between CS and L1, which can be used to determine the value of the capacitor. Equation 50 shows the basic energy balance.

where

is the ripple voltage across the SEPIC capacitor, and

is the ripple current through the inductor L1. The energy balance equation can be solved using Equation 53 to provide a minimum value for CS.

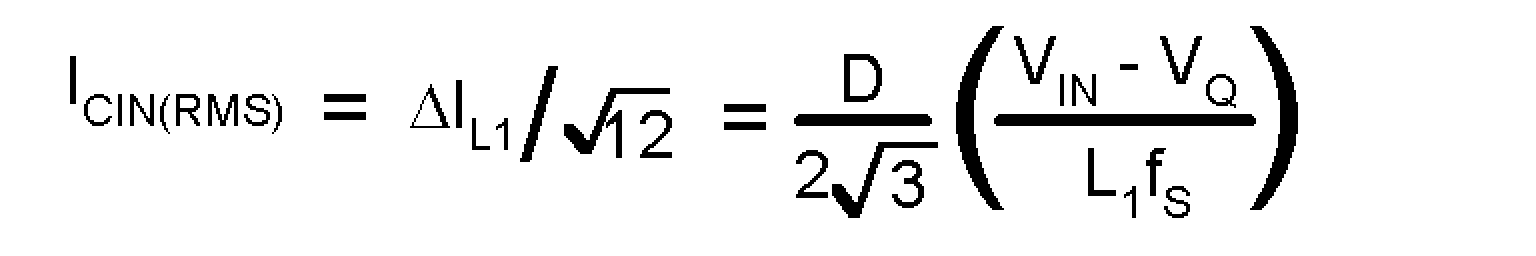

8.2.2.2.6 Input Capacitor Selection

Similar to a boost converter, the SEPIC has an inductor at the input. Hence, the input current waveform is continuous and triangular. The inductor ensures that the input capacitor sees fairly low ripple currents. However, as the input capacitor gets smaller, the input ripple goes up. The RMS current in the input capacitor is given using Equation 54.

The input capacitor should be capable of handling the RMS current. Although the input capacitor is not as critical in a boost application, low values can cause impedance interactions. Therefore a good quality capacitor should be chosen in the range of 10µF to 20µF. If a value lower than 10 µF is used, then problems with impedance interactions or switching noise can affect the LM3478. To improve performance, especially with VIN below 8 volts, TI recommends that the user uses a 20Ω resistor at the input to provide a RC filter. The resistor is placed in series with the VIN pin with only a bypass capacitor attached to the VIN pin directly (see Figure 31). A 0.1-µF or 1-µF ceramic capacitor is necessary in this configuration. The bulk input capacitor and inductor will connect on the other side of the resistor with the input power supply.

8.2.2.2.7 Output Capacitor Selection

The output capacitor of the SEPIC sees very large ripple currents (similar to the output capacitor of a boost converter). The RMS current through the output capacitor is given using Equation 55.

The ESR and ESL of the output capacitor directly control the output ripple. Use low capacitors with low ESR and ESL at the output for high efficiency and low ripple voltage. Surface mount tantalums, surface mount polymer electrolytic and polymer tantalum, Sanyo-OSCON, or multi-layer ceramic capacitors are recommended at the output for low ripple.

8.2.2.3 Application Curves