JAJSKM1C october 2019 – september 2021 UCC5870-Q1

PRODUCTION DATA

- 1

- 1 特長

- 2 アプリケーション

- 3 概要

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Power Supplies

- 7.3.2 Driver Stage

- 7.3.3 Integrated ADC for Front-End Analog (FEA) Signal Processing

- 7.3.4 Fault and Warning Classification

- 7.3.5

Diagnostic Features

- 7.3.5.1 Undervoltage Lockout (UVLO) and Overvoltage Lockout (OVLO)

- 7.3.5.2 CLAMP, OUTH, and OUTL Clamping Circuits

- 7.3.5.3 Active Miller Clamp

- 7.3.5.4 DESAT based Short Circuit Protection (DESAT)

- 7.3.5.5 Shunt Resistor based Overcurrent Protection (OCP) and Short Circuit Protection (SCP)

- 7.3.5.6 Temperature Monitoring and Protection for the Power Transistors

- 7.3.5.7 Active High Voltage Clamping (VCECLP)

- 7.3.5.8 Two-Level Turn-Off

- 7.3.5.9 Soft Turn-Off (STO)

- 7.3.5.10 Thermal Shutdown (TSD) and Temperature Warning (TWN) of Driver IC

- 7.3.5.11 Active Short Circuit Support (ASC)

- 7.3.5.12 Shoot-Through Protection (STP)

- 7.3.5.13 Gate Voltage Monitoring and Status Feedback

- 7.3.5.14 VGTH Monitor

- 7.3.5.15 Cyclic Redundancy Check (CRC)

- 7.3.5.16 Configuration Data CRC

- 7.3.5.17 SPI Transfer Write/Read CRC

- 7.3.5.18 TRIM CRC Check

- 7.4 Device Functional Modes

- 7.5 Programming

- 7.6 Register Maps

- 8 Applications and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

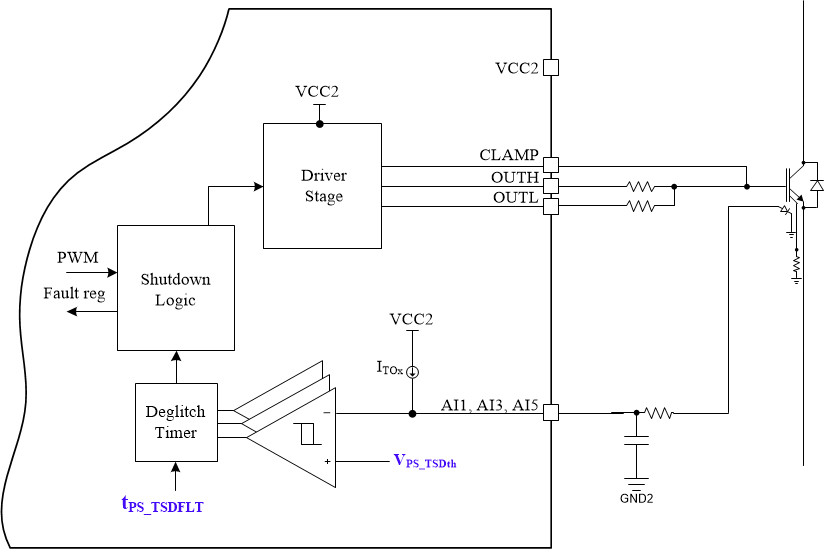

7.3.5.6 Temperature Monitoring and Protection for the Power Transistors