JAJU837 March 2022

2.3.1 Magnet Selection

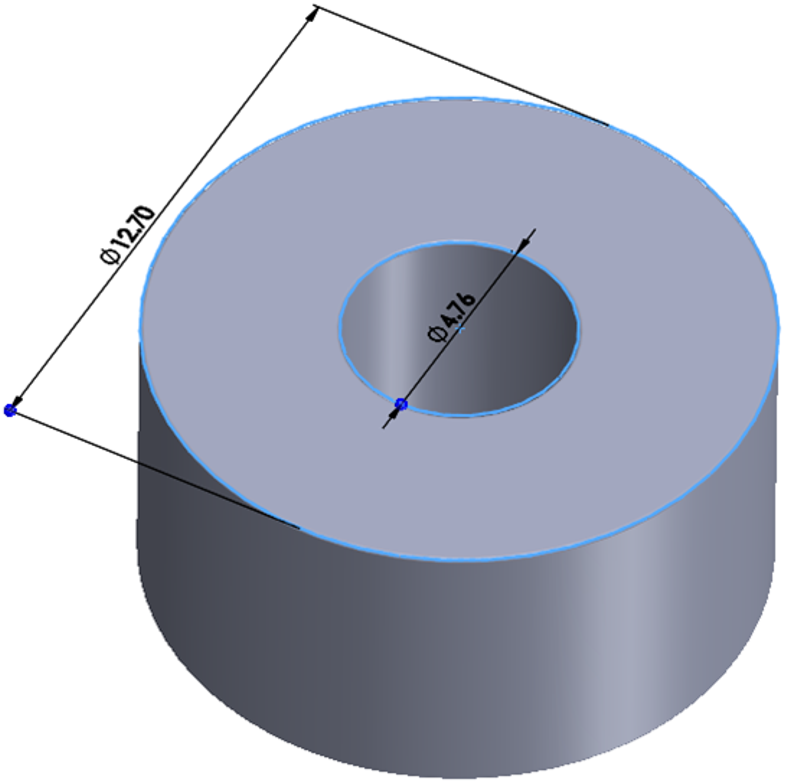

The magnet selected for testing was R834DIA, an N42 Grade diametric ring magnet. The magnet is specified with an inner diameter of 4.75 mm (0.1875 in) and an outer diameter of 12.7 mm (0.5 in). The magnet thickness is 6.35 mm (0.25 in).

Figure 2-2 Diametric Ring Magnet

Figure 2-2 Diametric Ring Magnet