SLVK086A january 2022 – may 2023 TPS7H4003-SEP

PRODUCTION DATA

- 1

- Single-Event Effects Test Report of the TPS7H4003-SEP Synchronous Step-Down Converter

- Trademarks

- 1 Introduction

- 2 Single-Event Effects (SEE)

- 3 Device and Test Board Information

- 4 Irradiation Facility and Setup

- 5 Depth, Range, and LETEFF Calculation

- 6 Test Setup and Procedures

- 7 Destructive Single-Event Effects (DSEE)

- 8 Single-Event Transients (SET)

- 9 Event Rate Calculations

- 10Summary

- A Appendix: Total Ionizing Dose From SEE Experiments

- B Appendix: References

- C Revision History

6 Test Setup and Procedures

SEE testing was performed on a TPS7H4003-SEP device mounted on a TPS7H4003 evaluation module. The device power was provided using the J19 (PVIN) and (GND) inputs with the N6766A PS Module mounted on a N6705 precision power supply in a 4-wire configuration. The Constant Current mode on a E3600 Chroma Load was used to load the device to 18 A for the SEE testing campaign.

For SEL, SEB, and SEGR testing, the device was powered up to the maximum recommended operating voltage of 7 V and loaded with the maximum load of 18 A. 1 V was used at the output voltage for the SEE testing campaign. For the SEB/SEGR characterization, the device was tested under enabled and disabled modes. The device was enabled/disabled by using the TP2 and forcing EN to either 5 V or 0 V using a E36311A power supply. The Chroma Load was connected even when the device was disabled to help differentiate if an SET momentarily activated the device under the heavy-ion irradiation. During the SEB/SEGR testing with the device in disabled mode, not a single VOUT transient or input current event was observed.

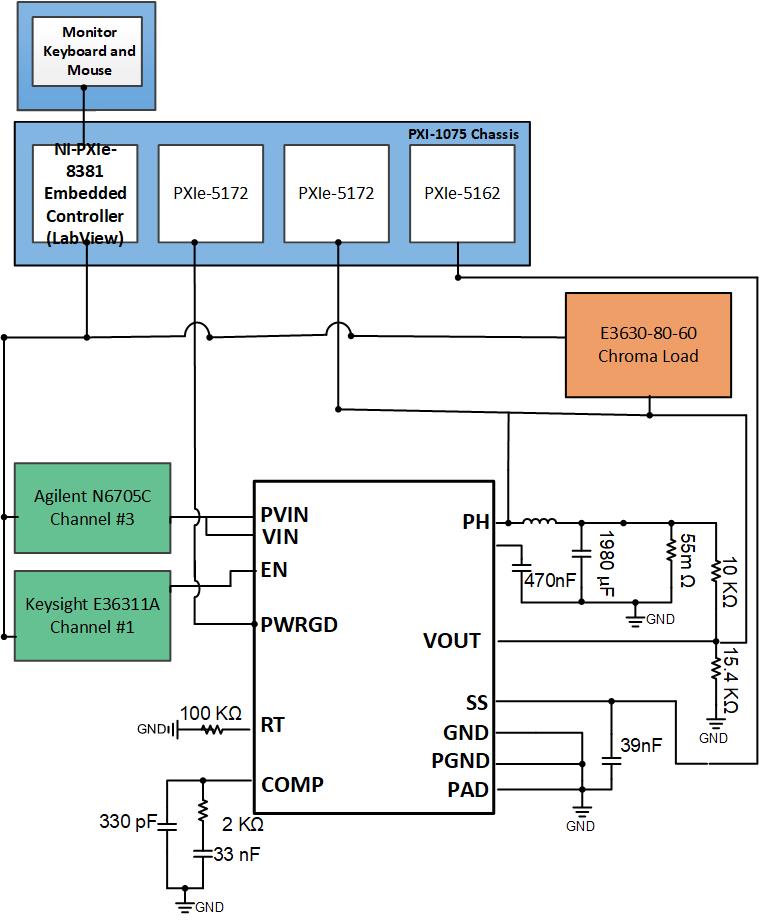

For the SET characterization, the device was powered up to 5, 6, and 6.5 V with a VOUT of 1 V. The SET events were monitored using two National Instruments™ (NI) PXIe-5172 scope cards and one NI PXIe-5162 scope card. One 5172 scope was used to monitor VOUT and Phase while triggering from VOUT, using a window trigger around ±3% from the nominal output voltage. The second 5172 scope was used to monitor PGOOD and VOUT while triggering from PGOOD at VIN – 0.5 V using an edge/negative trigger. The PXIe-5162 scope was used to monitor and trigger from SS at 0.5 V using an edge/negative trigger. All three scopes were mounted on a NI PXIe-1095 chassis.

All equipment was controlled and monitored using a custom-developed LabVIEW™ program (PXI-RadTest) running on a HP-Z4® desktop computer. The computer communicates with the PXI chassis via a MXI controller and NI PXIe-8381 remote control module.

Figure 6-1 shows a block diagram of the setup used for SEE testing of the TPS7H4003-SEP. Table 6-1 shows the connections, limits, and compliance values used during the testing. A die temperature of 125°C used for SEL was achieved with the use of a convection heat gun aimed at the die. For SET and SEB/SEGR testing, the device was tested at room temperature (no cooling or heating was applied to the DUT). The die temperature was monitored throughout testing by a T-Type thermocouple attached to the thermal pad vias (on the bottom side of the EVM) with thermal paste. The thermocouple was held in place by using high temperature tape (kapton-tape). Die-to-thermocouple temperature was verified using a IR-camera prior to the SEE testing campaign.

| PIN NAME | EQUIPMENT USED | CAPABILITY | COMPLIANCE | RANGE OF VALUES USED |

|---|---|---|---|---|

| VIN | Agilent N6700 PS (Channel #3) | 15 A | 10 A | 5, 6, 6.5, and 7 V |

| EN | Keysight E36311A PS (Channel #1) | 5 A | 100 mA | 0 V (disabled) and 5 V (enabled) |

| Oscilloscope card on VOUT | NI-PXIe 5172 | 100 MS/s | — | 10 MS/s |

| Oscilloscope card on PGOOD | NI-PXIe 5172 | 100 MS/s | — | 50 MS/s |

| Oscilloscope card on SS | NI-PXIe 5162 | 100 MS/s | — | 50 MS/s |

| Load | Chroma-E3630-80-60 (Channel #1) | 60 A | Range: High | 18 A |

| Digital I/O | NI-PXIe 6589 | — | — | Interrupt Based |

All boards used for SEE testing were fully checked for functionality. Dry runs were also performed to ensure that the test system was stable under all bias and load conditions prior to being taken to the TAMU facility. During the heavy-ion testing, the LabVIEW control program powered up the TPS7H4003-SEP device and set the external sourcing and monitoring functions of the external equipment. After functionality and stability were confirmed, the beam shutter was opened to expose the device to the heavy-ion beam. The shutter remained open until the target fluence was achieved (determined by external detectors and counters). During irradiation, the NI scope cards continuously monitored the signals. When output voltage exceeded the pre-defined ±3% window trigger, or when the PG signal changed from High to Low (using a negative edge trigger), a data capture was initiated. In addition to monitoring the voltage levels of the two scopes, VIN current and the +5-V signal from TAMU were monitored at all times. No sudden increases in current were observed (outside of normal fluctuations) on any of the test runs and indicated that no SEL or SEB/SEGR events occurred during any of the tests.

Figure 6-1 Block Diagram of SEE Test

Setup With the TPS7H4003-SEP

Figure 6-1 Block Diagram of SEE Test

Setup With the TPS7H4003-SEP