SLLA576 June 2022 DRV10987 , MCF8316A , MCT8316A

2.1.1 Align

Below are the steps to tune the motor to achieve faster startup time using Align as the motor startup method:

- Select align as the motor startup method in [MTR_STARTUP].

- Configure align time [ALIGN_TIME]

to 5 ms.Note: Ensure the rotor settles to a position and does not oscillate. If the rotor oscillates before spinning in open loop, increase the align time [ALIGN_TIME].

- Select Open loop current limit

[OL_ILIMIT] to be the same as cycle by cycle current limit [ILIMIT].Note: If the device triggers cycle by cycle current limit [CBC_ILIMIT], it is recommended to increase [ILIMIT] up to the stall current of the motor. Configuring this to a value higher than motor stall current might overheat or damage the motor.

- Increase Open loop acceleration

coefficient A1 [OL_ACC_A1] and Open loop acceleration coefficient A2

[OL_ACC_A2].Note: A1 and A2 can be increased until open loop current reaches Lock detection current threshold [LOCK_ILIMIT]. Open loop current can be measured using oscilloscope.

Increasing Open loop acceleration coefficient A1 [OL_ACC_A1] and Open loop acceleration coefficient A2 [OL_ACC_A2] might trigger LOCK_LIMIT or CBC_ILIMIT. If this happens, reduce A1 and A2 until LOCK_LIMIT no longer triggers.

For ultra-fast startup time (less than 100 ms) it is recommended to follow below steps:

- Disable auto-handoff [AUTO_HANDOFF].

- Configure Open loop handoff cycles [OL_HANDOFF_CYCLES] to 3.

- Configure INTEG_ZC_METHOD to Integration.

- Enable Dynamic degauss [DYN_DEGAUSS_EN].

- Configure open to closed loop handoff threshold [OPN_CL_HANDOFF_THR] to a value lesser than or equal to 20 Hz.

For startup times above 100 ms, it is recommended to follow below steps:

- Enable auto-handoff [AUTO_HANDOFF].

- Configure Open loop handoff cycles [OL_HANDOFF_CYCLES] to 6.

- Enable Dynamic degauss

[DYN_DEGAUSS_EN].Note: If Abnormal speed fault [ABN_SPEED] gets triggered, it is recommended to decrease open loop acceleration constants [OL_ACC_A1] and [OL_ACC_A2] and also retune IPD by increasing the IPD current threshold [IPD_CURR_THR] and IPD repeat times [IPD_REPEAT].

- Increase Closed loop acceleration rate [CL_ACC]

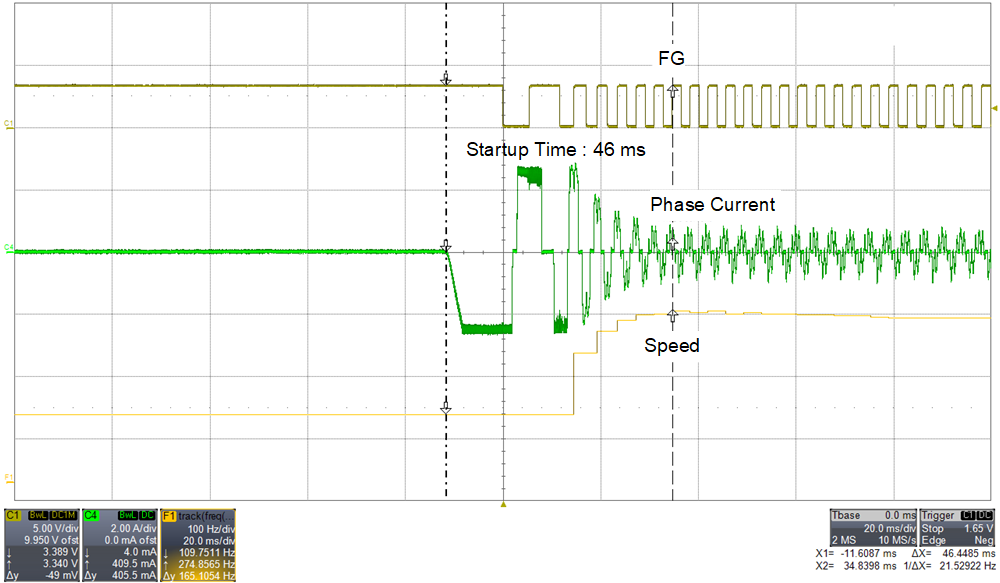

Figure 2-1 shows the phase current, FG and Speed curve when the motor is started using Align as the startup method. Time taken for the motor to accelerate to 100% duty cycle is around 46 ms.

Figure 2-1 Startup Time Using Align as

Motor Startup Method

Figure 2-1 Startup Time Using Align as

Motor Startup Method