SLLA576 June 2022 DRV10987 , MCF8316A , MCT8316A

2.2 Minimizing Acceleration and Deceleration Slew Rate

Below are the steps to tune the motor to achieve fast acceleration in closed loop:

- Enable Dynamic degauss [DYN_DEGAUSS_EN].

- Configure Closed loop acceleration rate to 1000V/s.

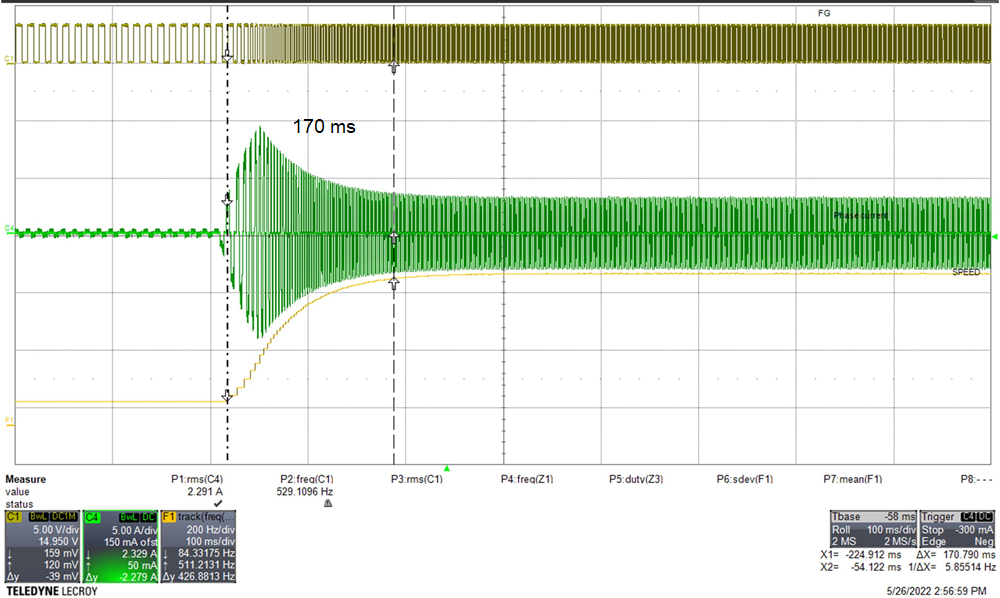

Figure 2-3 shows phase current, FG and speed curve when the motor accelerates from 10% duty cycle to 100% duty cycle. Time taken for the motor to accelerate from 10% duty cycle to 100% duty cycle is around 170 ms.

Figure 2-3 Fast Acceleration

Figure 2-3 Fast AccelerationBelow are the steps to tune the motor to achieve fast deceleration:

- Configure closed loop deceleration [CL_DEC] to a value that is same as closed loop acceleration [CL_ACC].

- Enable Fast deceleration [FAST_DECEL_EN].

- Configure Fast deceleration current limit [FAST_DECEL_CURR_LIM]. Fast deceleration current limit will be higher for motors with higher inertia.

- Enable AVS [AVS_EN] to protect the power supply from voltage overshoots during motor deceleration. If AVS is enabled, the time taken to decelerate the motor will increase. Disable AVS, if the power supply can withstand voltage overshoots.

- Configure Fast Decel Brake Threshold [FAST_BRK_DELTA] if the fast deceleration should be disabled before the actual motor speed reaches the target speed. For example, if the Fast Decel Brake Threshold [FAST_BRK_DELTA] is configured to 0.5% and target duty cycle is configured to 5%, device will stop decelerating the motor at 5.5%. This can be helpful in applications where the motor is decelerated to critically low speeds. While the motor decelerates quickly to critically low speeds, there are possibilities that the motor might stop. In such applications, it is required to stop decelerating the motor at slightly higher speeds to avoid the device from completely stopping the motor.

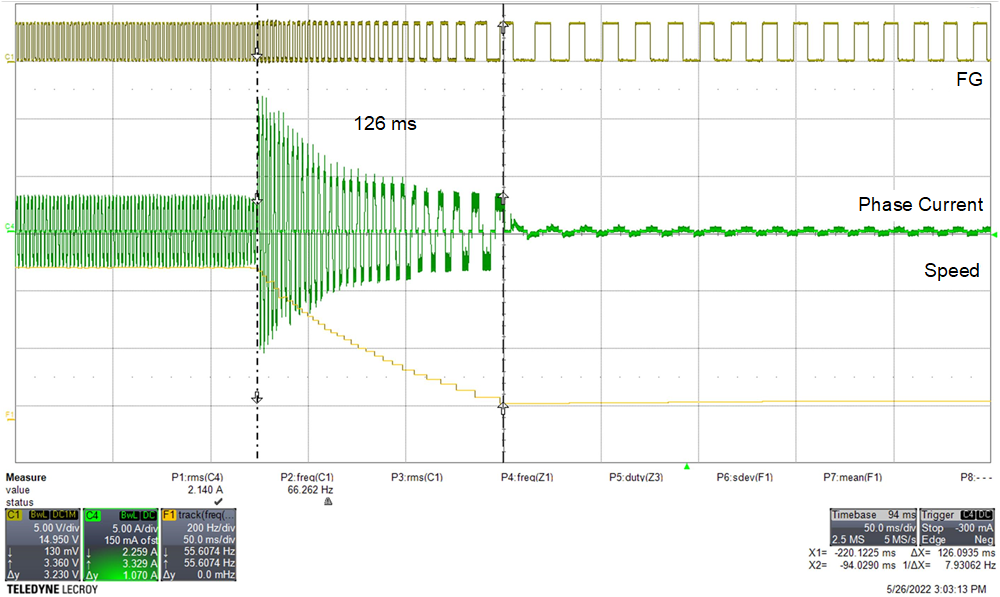

Figure 2-4 shows phase current, FG and speed curve when the motor decelerates from 100% duty cycle to 10% duty cycle. Time taken for the motor to decelerate from 100% duty cycle to 10% duty cycle when fast delegation is disabled is around 126 ms.

Figure 2-4 Fast Deceleration

Figure 2-4 Fast DecelerationMCT8316A provides a dynamic current limit option during fast deceleration to improve the stability of fast deceleration when braking to very low speeds. Using this feature, the current limit during fast deceleration can be reduced as the motor speed decreases.

If motor stalls at lower speeds, it is recommended to follow below steps:

- Enable dynamic decrease in current limit [DYNAMIC_BRK_CURR].

- Configure FAST_DEC_DUTY_THR. This sets the speed below which fast deceleration will be implemented. For example, if FAST_DEC_DUTY_THR is set to 70%, any deceleration from speeds above 70% will not use fast deceleration until the speed goes below 70%. If AVS is enabled, AVS will be active when motor decelerates from 100% to 70% duty cycle.

- Configure DYN_BRK_CURR_LOW_LIM. This sets the current limit at zero speed.

- Configure FAST_DEC_DUTY_WIN. This

is used to set the minimum deceleration window (initial speed - target speed)

below which fast deceleration will not be implemented. For example, if

FAST_DEC_DUTY_WIN is set to 7.5%, FAST_DEC_DUTY_THR is set to 75% and 75% to 50%

deceleration command is received, fast deceleration will be active below 67.5%.

If FAST_DEC_DUTY_WIN is set to 15% and 50%->40% deceleration command is

received, fast deceleration is not used to reduce the speed from 50% to 40%

since the deceleration window (10%) is smaller than FAST_DEC_DUTY_WIN.Note: Disable WCOMP_BLANK_EN if voltage spikes are seen on supply voltage.