SLUUBH3A November 2016 – February 2022 TPS546C20A

- Trademarks

- 1 Description

- 2 Electrical Performance Specifications

- 3 Schematic

- 4 Test Setup

- 5 EVM Configuration Using the Fusion GUI

- 6 Test Procedure

- 7 Performance Data and Typical Characteristic Curves

- 8 EVM Assembly Drawing and PCB Layout

- 9 Bill of Materials

- 10Screenshots

- 11Revision History

10.1 Fusion GUI Screenshots

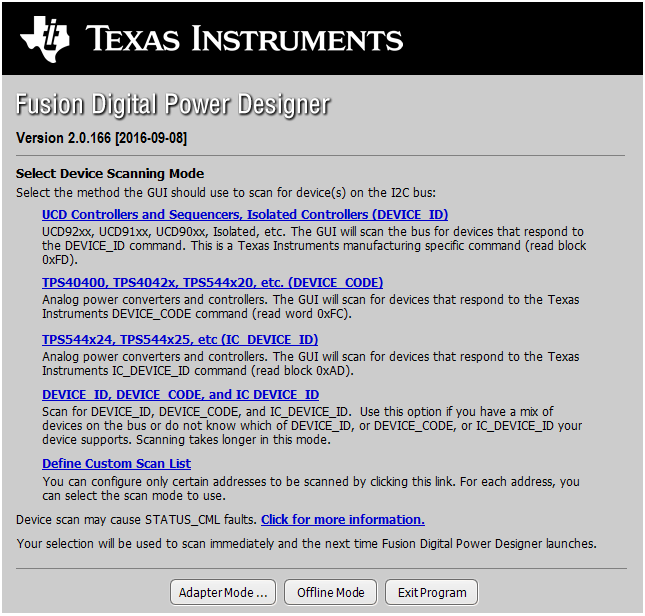

When launching the Fusion GUI, select IC_DEVICE_ID (Figure 10-1) as the scanning mode to find the TPS546C20A.

Figure 10-1 Select Device Scanning Mode

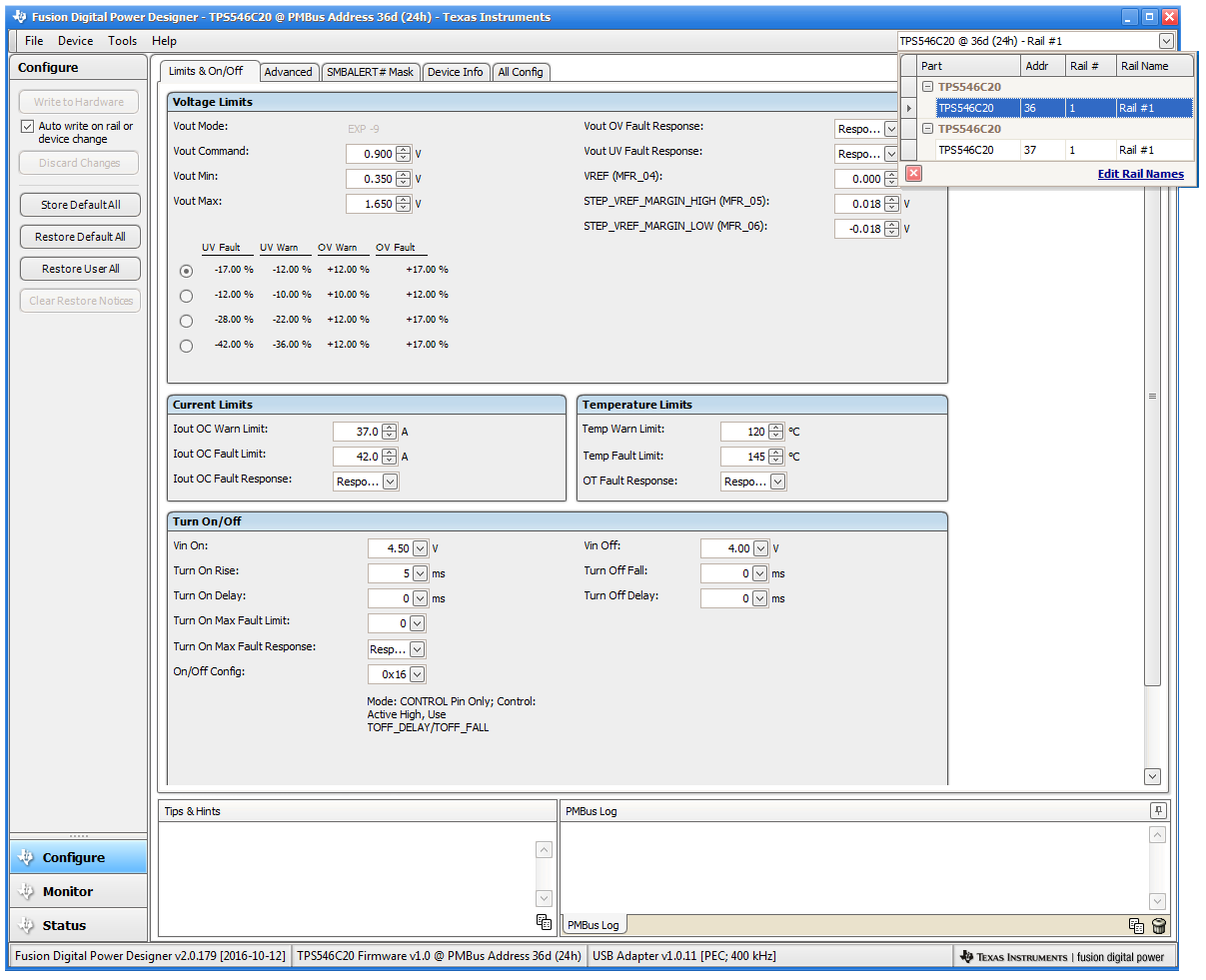

Figure 10-1 Select Device Scanning Mode- Use the Limits & On/Off tab (Figure 10-2) to configure the following:

- Vref (Vout_Command)

- OC fault and OC warn

- OT fault and OT warn (die temperature)

- Power-good limits

- Fault response

- UVLO

- On/Off config

- Soft-start time (turn-on rise)

- Margin voltage

After making changes to one or more configurable parameters, the changes can be committed to nonvolatile memory by clicking Store DefaultAll. This action prompts a confirm selection pop-up, and if confirmed, the changes are committed to nonvolatile memory to store all the modifications in non-volatile memory.

For modifications on Vref and soft-start time, to make the changes effective in next power up, DIS_VSEL in Advanced tab (Figure 10-4) should be checked and stored to nonvolatile memory as well.

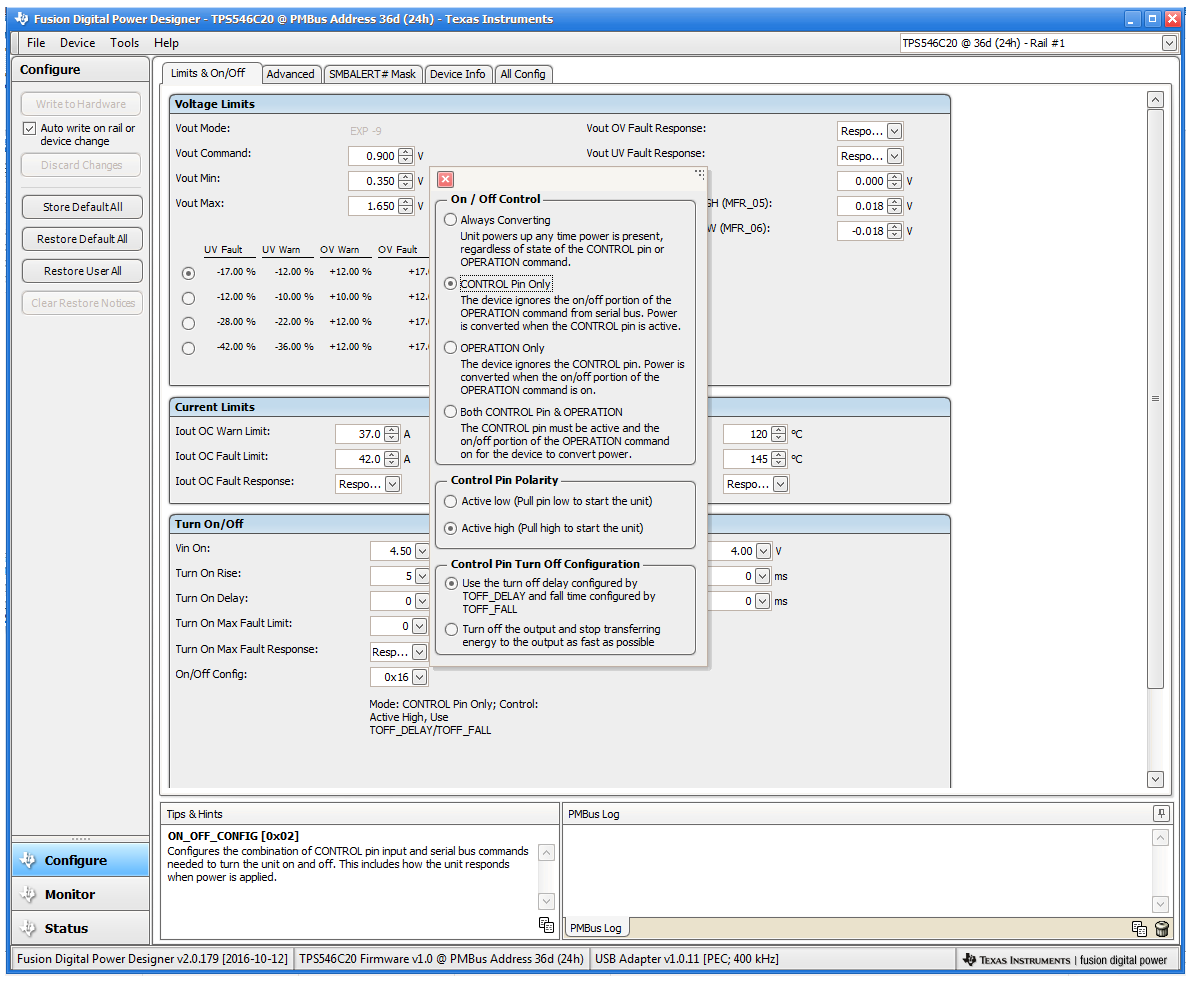

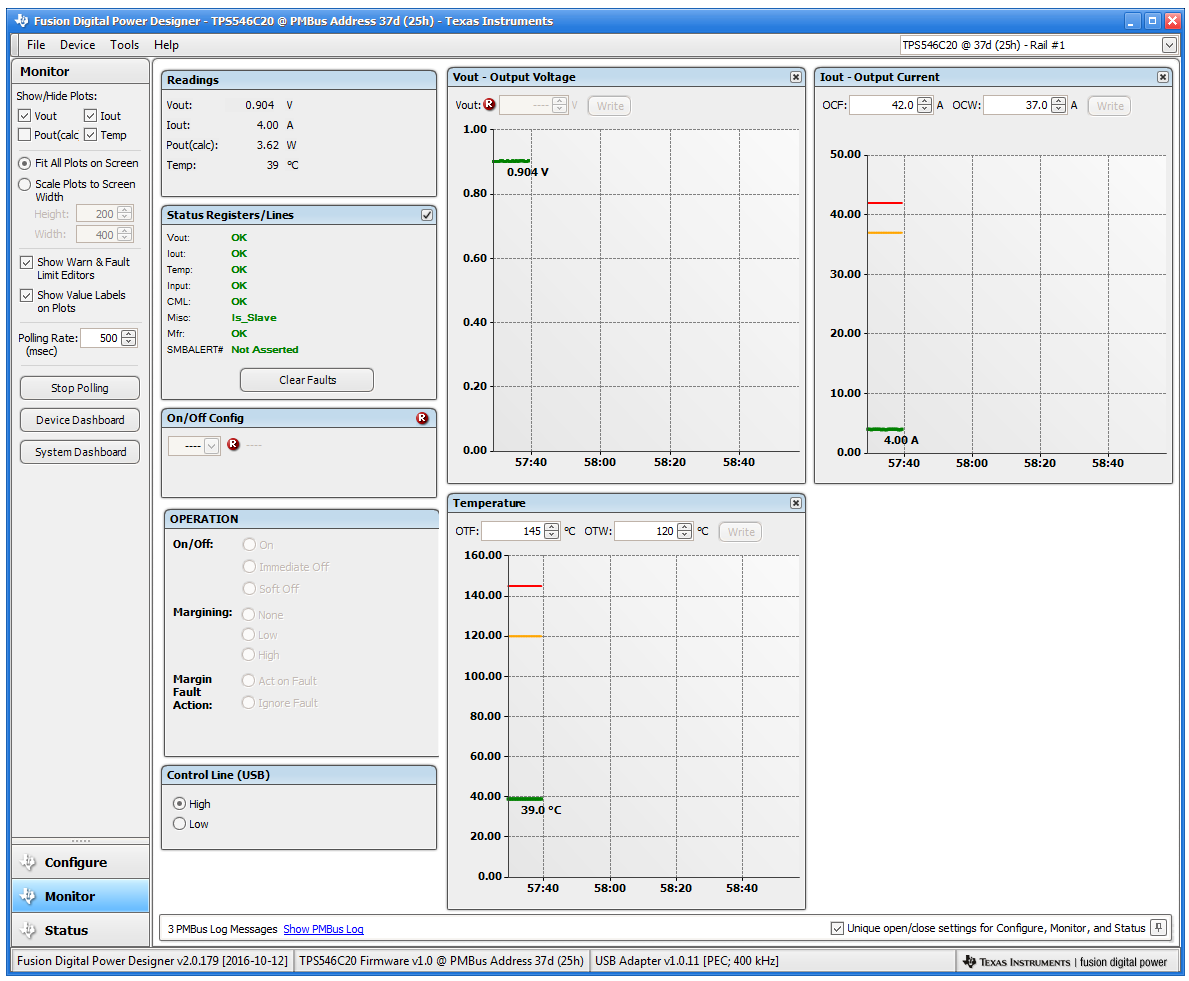

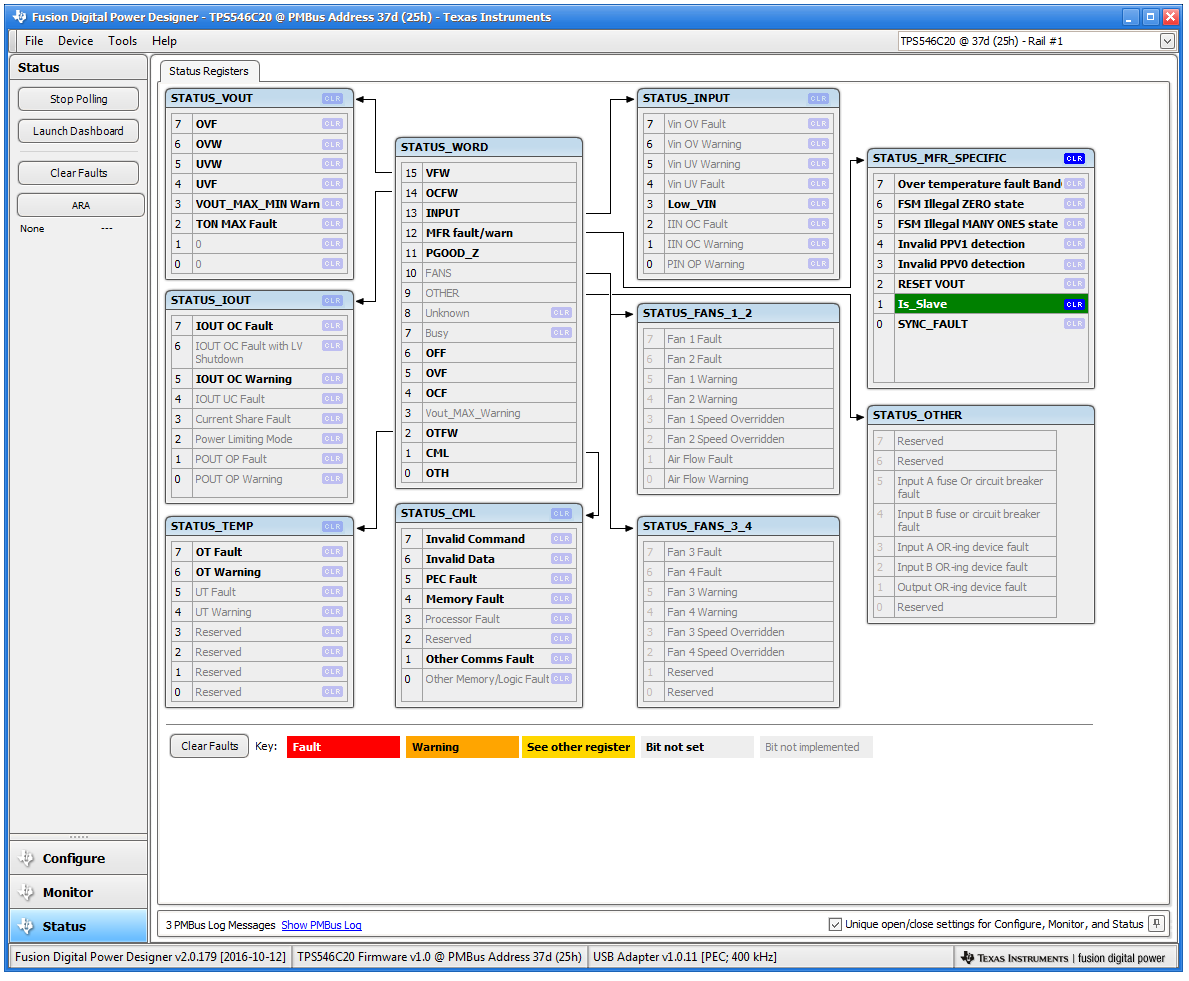

Both the loop controller device and the loop follower device are tied to same bus interface, a scroll-down menu in the upper right corner can be used to switch view screens from one to the other. In two-phase stacking system, most configurable parameters are disabled in GUI if the device is detected as loop follower (Figure 10-7).

Figure 10-2 Configure – Limits and

On/Off for U1 and U2

Figure 10-2 Configure – Limits and

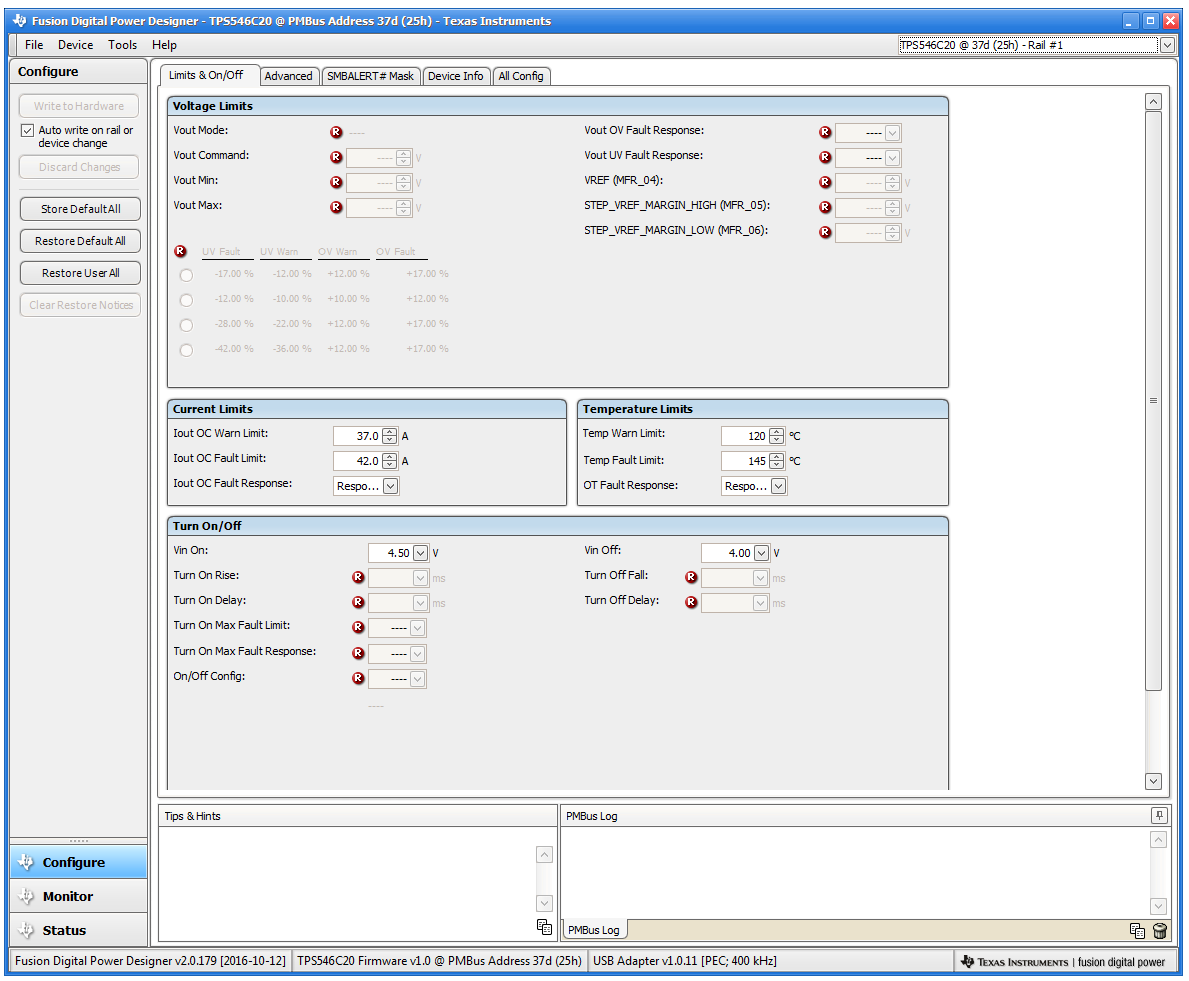

On/Off for U1 and U2Changing the on/off configuration prompts a pop-up window with details of the options (Figure 10-3).

Figure 10-3 ON/OFF Control Pop-Up

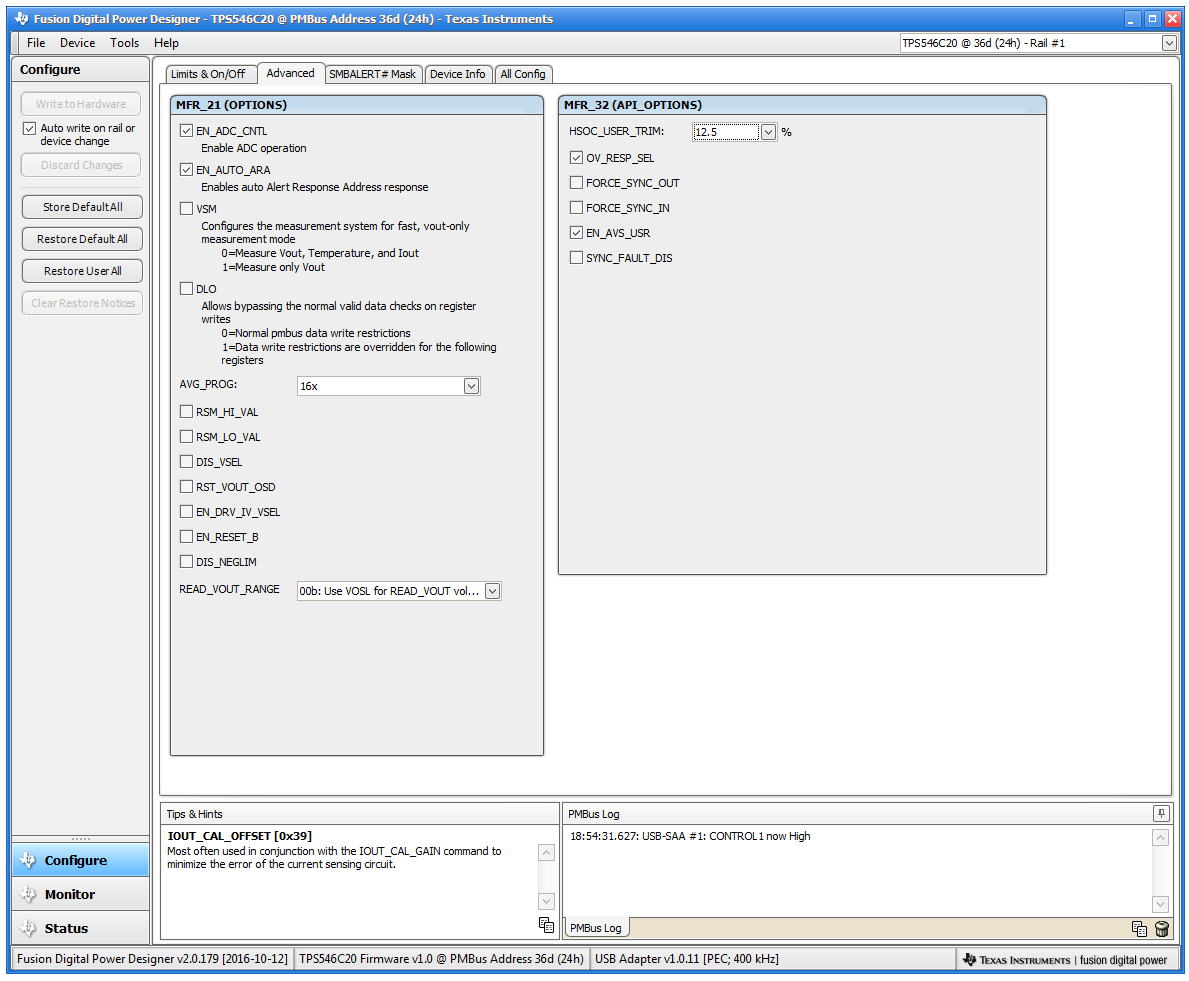

Figure 10-3 ON/OFF Control Pop-Up- Use the Advanced tab (Figure 10-4) to configure:

- OPTIONS: MFR_SPECIFIC_21 register

- API_OPTIONS: MFR_SPECIFIC_32 register

Figure 10-4 Configure –

Advanced

Figure 10-4 Configure –

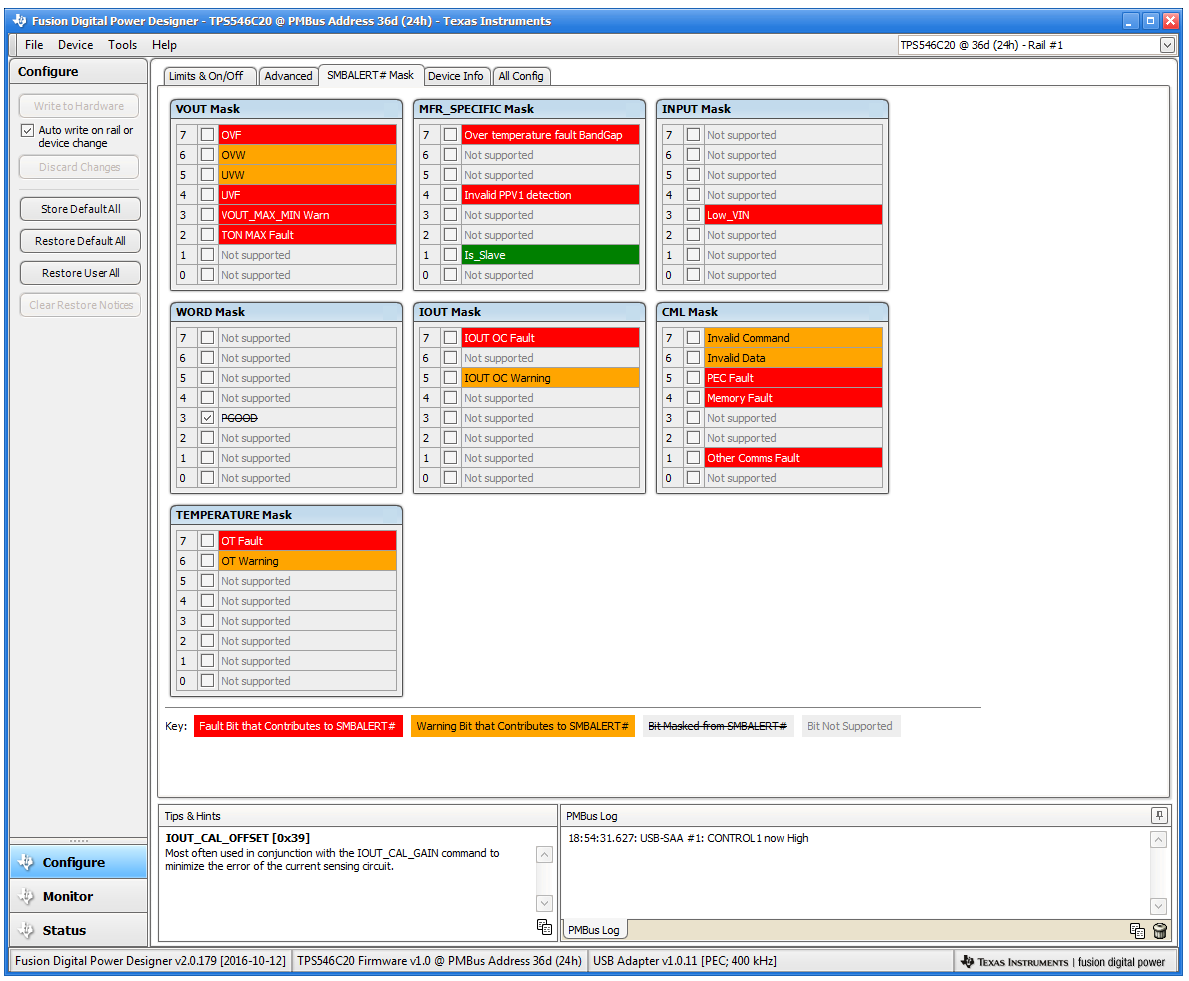

AdvancedThe sources of SMBALERT that can be masked can be found and configured on the SMBALERT # Mask tab (Figure 10-5).

Figure 10-5 Configure – SMBALERT # Mask

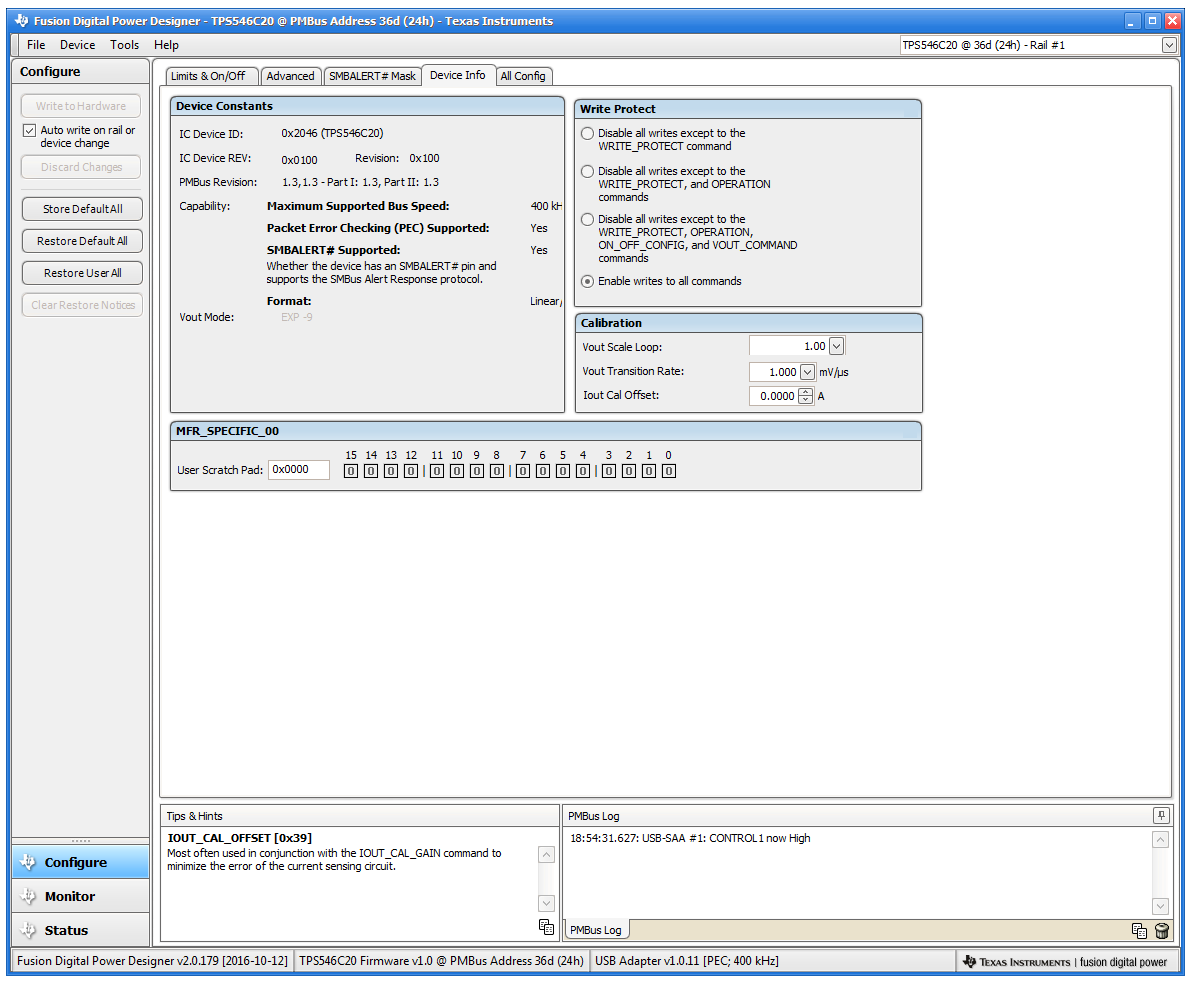

Figure 10-5 Configure – SMBALERT # MaskThe device information, User Scratch Pad, Write Protection options, and the configuration of Vout Scale Loop, Vout Transition Rate, and Iout Cal Offset can be found on Device Info tab (Figure 10-6).

Figure 10-6 Configure – Device Info

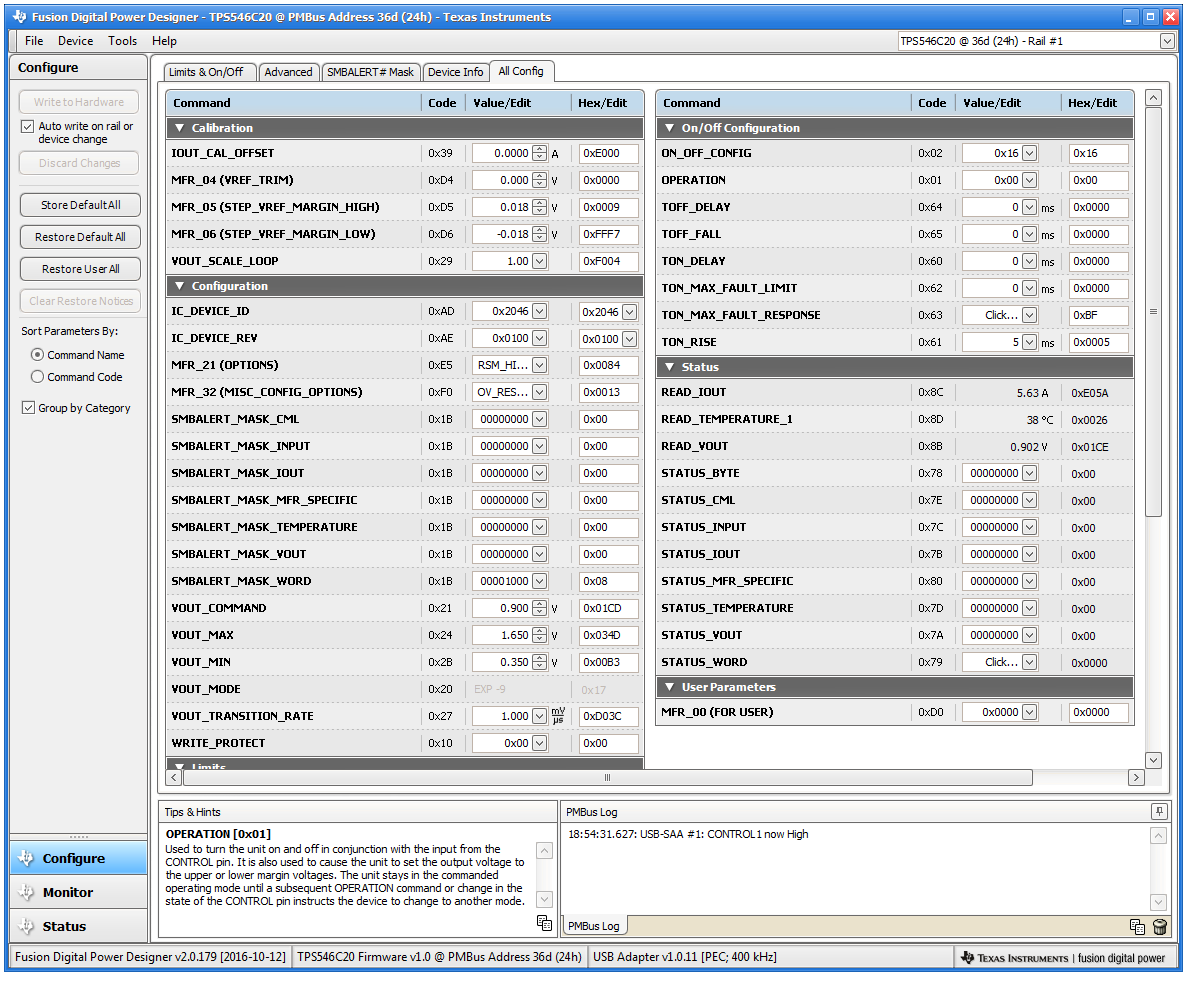

Figure 10-6 Configure – Device InfoUse the All Config tab (Figure 10-7) to configure all of the configurable parameters, which also shows other details like Hex encoding.

Figure 10-7 Configure – All

Config

Figure 10-7 Configure – All

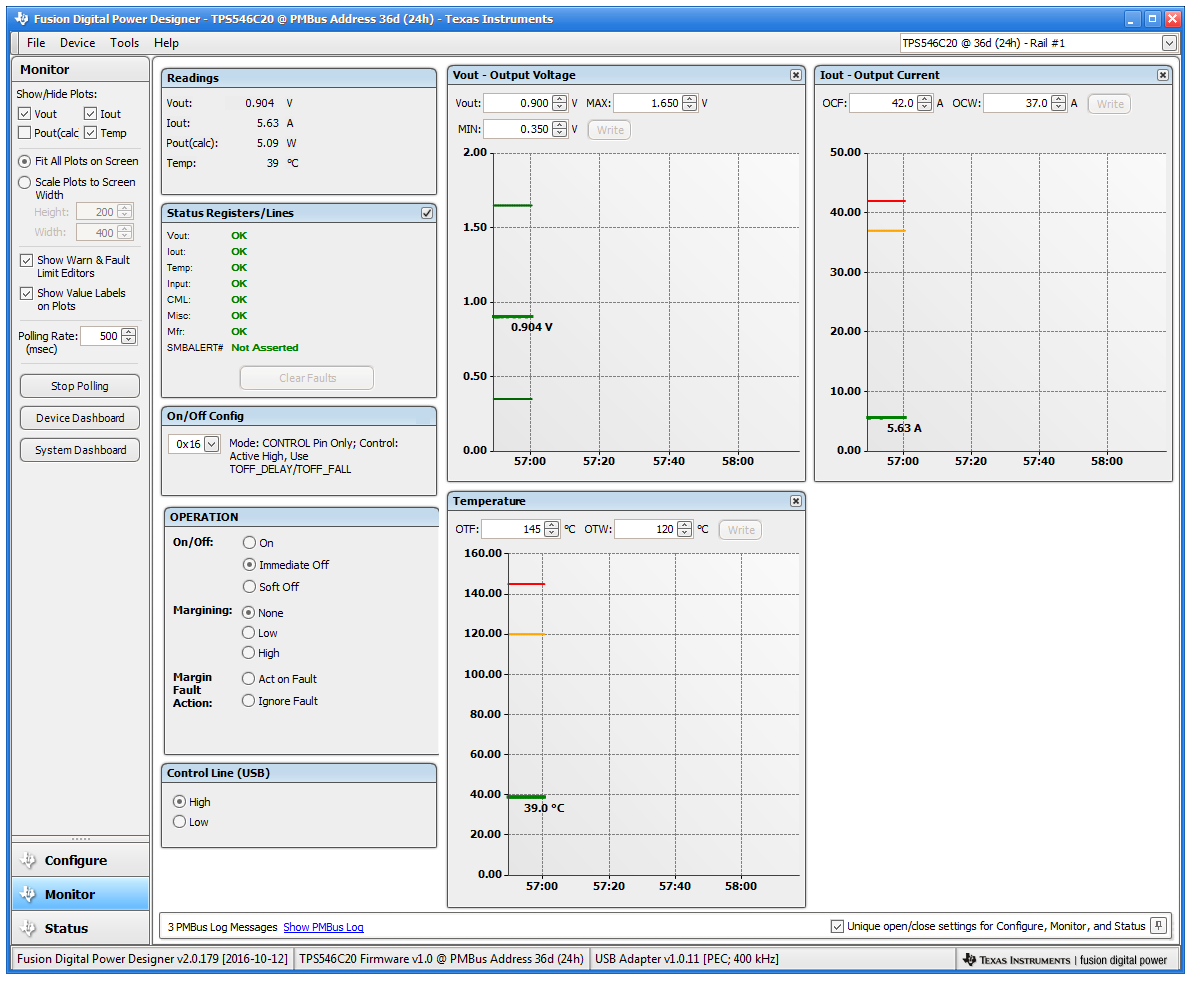

ConfigWhen the Monitor screen (Figure 10-8) is selected, the screen changes to display real-time data of the parameters that are measured by the device. This screen provides access to:

- Graphs of VOUT, Iout, Temperature, and Pout

- Start/Stop Polling, which turns ON or OFF the real-time display of data

- Quick access to On/Off config

- Control pin activation and OPERATION command

- Margin control

- Clear Fault. Selecting Clear Faults clears any prior fault flags.

With two devices stacked together, the IOUT reading from either the loop controller or the loop follower device is the load current supported by the device itself, thus the Iout reading is half of the total load.

Figure 10-8 Monitor Screen with 10-A

Total Load

Figure 10-8 Monitor Screen with 10-A

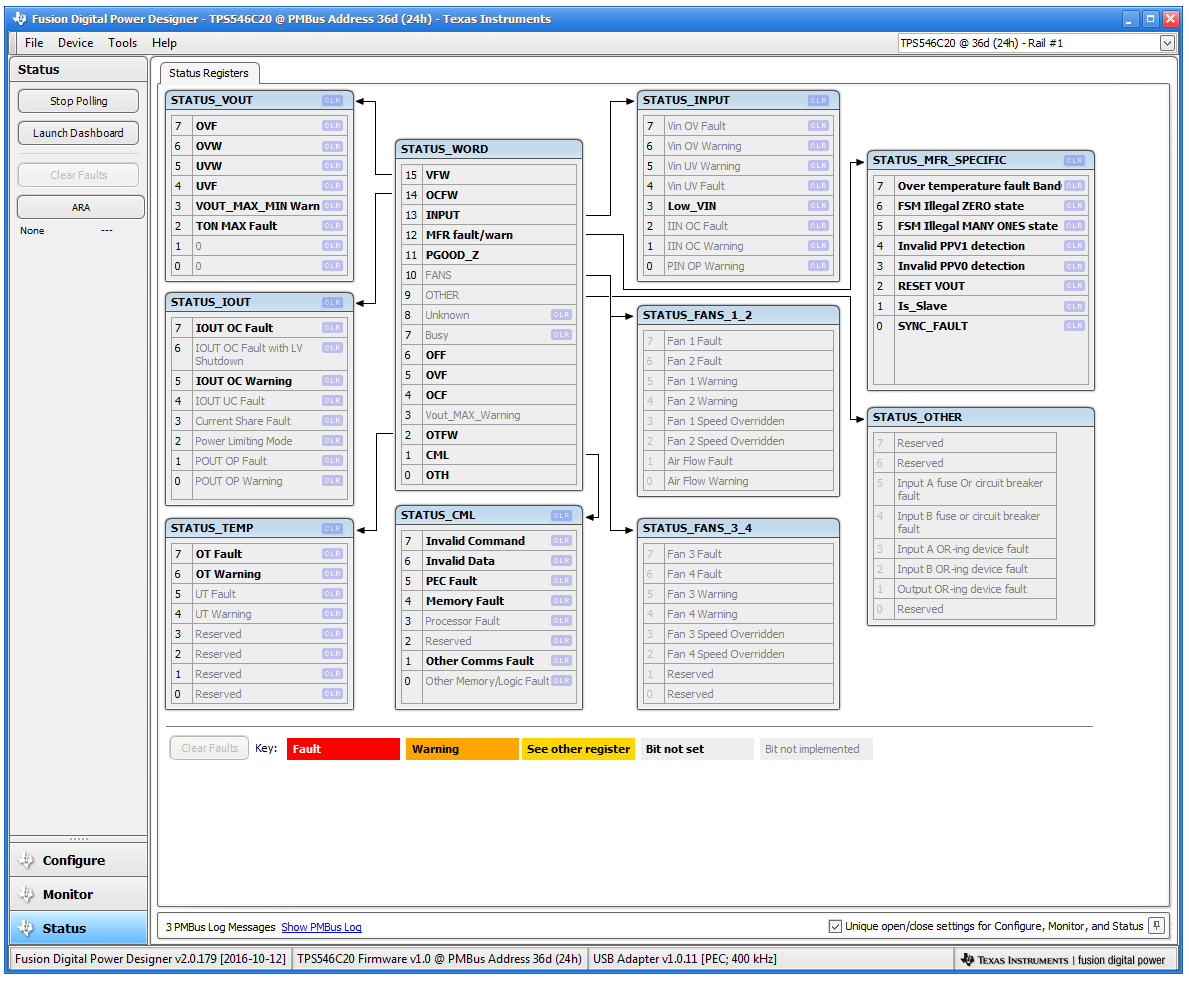

Total LoadSelecting Status screen (Figure 10-9) from lower left corner shows the status of the device.

Figure 10-9 Status Screen

Figure 10-9 Status Screen