SLUUCH4A October 2021 – October 2023 BQ27Z746 , BQ27Z758

- 1

- Abstract

- Trademarks

- 1 Software Setup

- 2 Troubleshooting Unexpected Dialog Boxes

- 3 Hardware Setup

- 4 Using bqStudio

- 5 Calibrating Gauge Measurements

- 6 Protections

- 7 Chemical ID

- 8 Learning Cycle and Golden Image

- 9 Gauge Communication

- 10BQ27Z746-Based Circuit Module

- 11Circuit Module Physical Layout, Bill of Materials, and Schematic

- Revision History

7.3 Logging Data in bqStudio

The recording of voltage, current, and temperature can be done with bqStudio. The logging functionality in bqStudio allows a constant capture and recording of the registers of a connected gauge. The default elapsed interval is 4000 milliseconds. To change this interval, go to Window, select Preferences, choose Registers, and change Scan/Log Interval from 4000 to a minimum of 1000 milliseconds. There is no need to log faster than 1 second as the gas gauge updates the registers once every second.

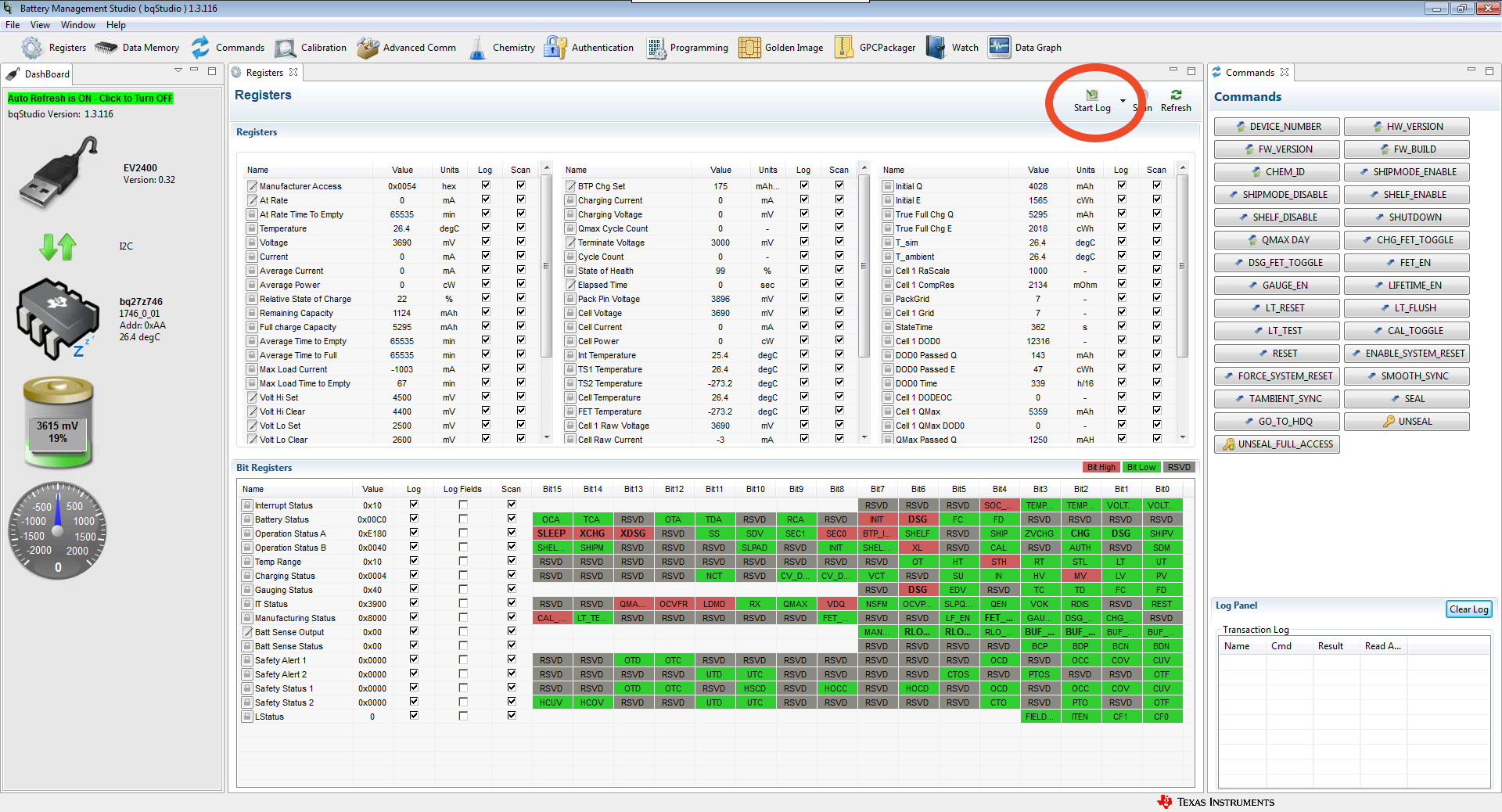

To begin recording the battery's IVT properties during charge and discharge, use the Start Log button on the Registers window in bqStudio as shown in Figure 7-3.

Figure 7-3 Start Log Button in bqStudio

Figure 7-3 Start Log Button in bqStudioUpon pressing the Start Log button, a prompt to select a location for the .log file to save will be shown. Select a location to save this file. The .log file type can be changed to the .csv format and viewed inside of Microsoft Excel™ or a similar application to facilitate debugging of the register states through the course of the logging period. At the end of the relaxation period after the gauge has been allowed to discharge, use the Stop Log button in bqStudio to end logging.