SLYT791A may 2020 – may 2020 LM25180 , LM25180-Q1 , LM25183 , LM25183-Q1 , LM25184 , LM25184-Q1 , LM5170-Q1 , LM5180 , LM5180-Q1 , LM5181 , LM5181-Q1 , UCC20225A-Q1

3 PSR Flyback Implementation

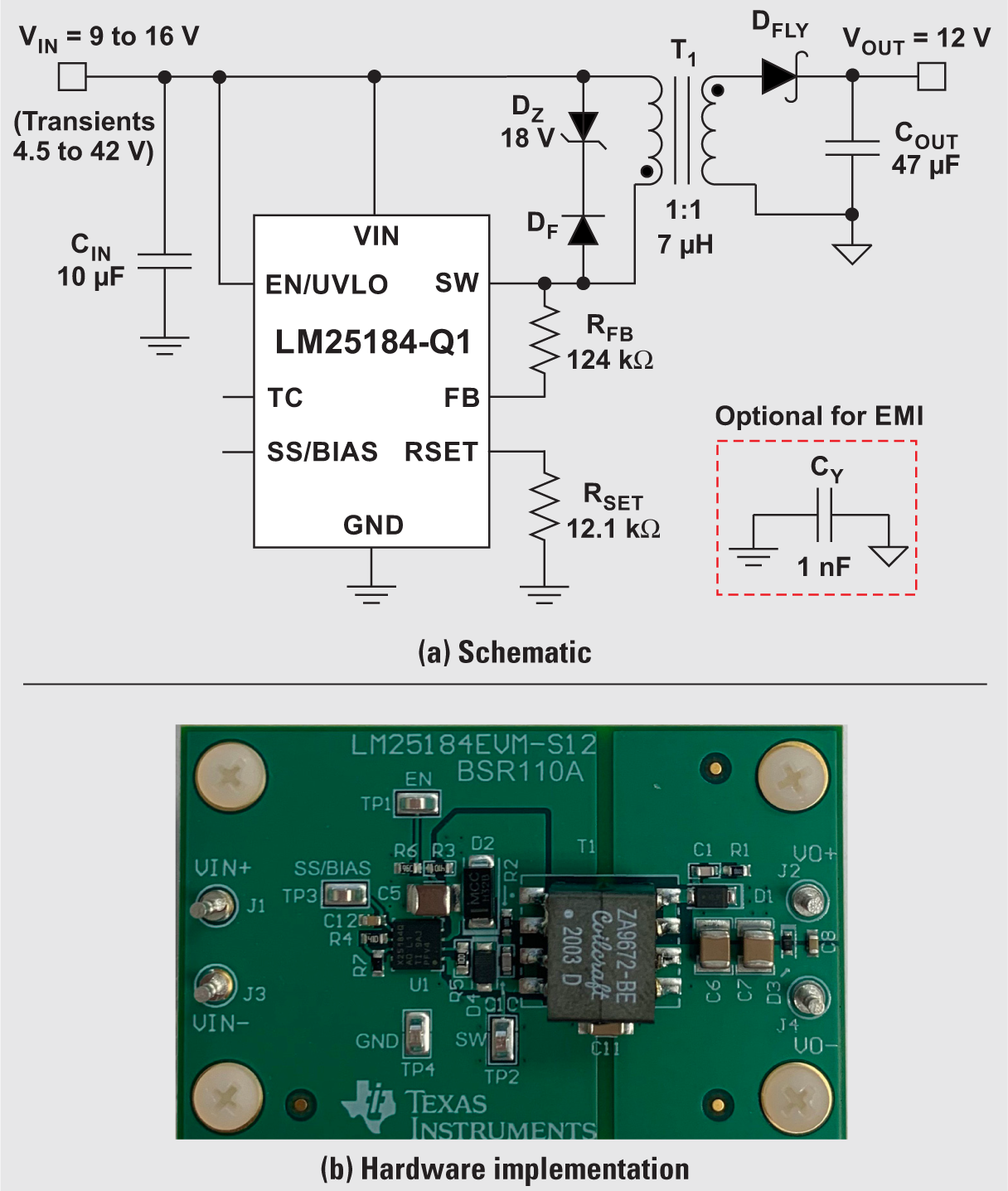

Suitable for low-power isolated rails in mHEVs, Figure 3a shows a schematic using the LM25184-Q1, a flyback converter with an integrated power switch and loop compensation that uses PSR for output voltage control. Depending on the load current, the PSR flyback converter operates in boundary conduction mode (BCM) or discontinuous conduction mode. A Zener diode circuit across the primary winding supports a clamped reset of the transformer leakage inductance. Figure 3b shows an implementation[8,9] that uses a flyback transformer with a 1-to-1 turns ratio, a magnetizing inductance of 7 µH and an 11- by 13-mm footprint.

The PSR architecture is an observer-based approach to estimate the output voltage of a flyback converter using a primary-referenced winding. Appropriately timed sensing of the switch voltage at its knee position provides a suitable proxy of the output voltage that enables the output to have very tight regulation accuracy across line, load and temperature ranges. Not using an optocoupler for feedback eliminates the need for a component to cross the isolation barrier and provides a more cost-effective solution. Moreover, an auxiliary winding for output sensing is not required, thus enabling a simpler magnetic structure with lower leakage inductance[10] and opening up more choices in terms of off-the-shelf components that include Q-grade compliance.

Figure 3 Auxless PSR Flyback Converter

with a 12-V Output

Figure 3 Auxless PSR Flyback Converter

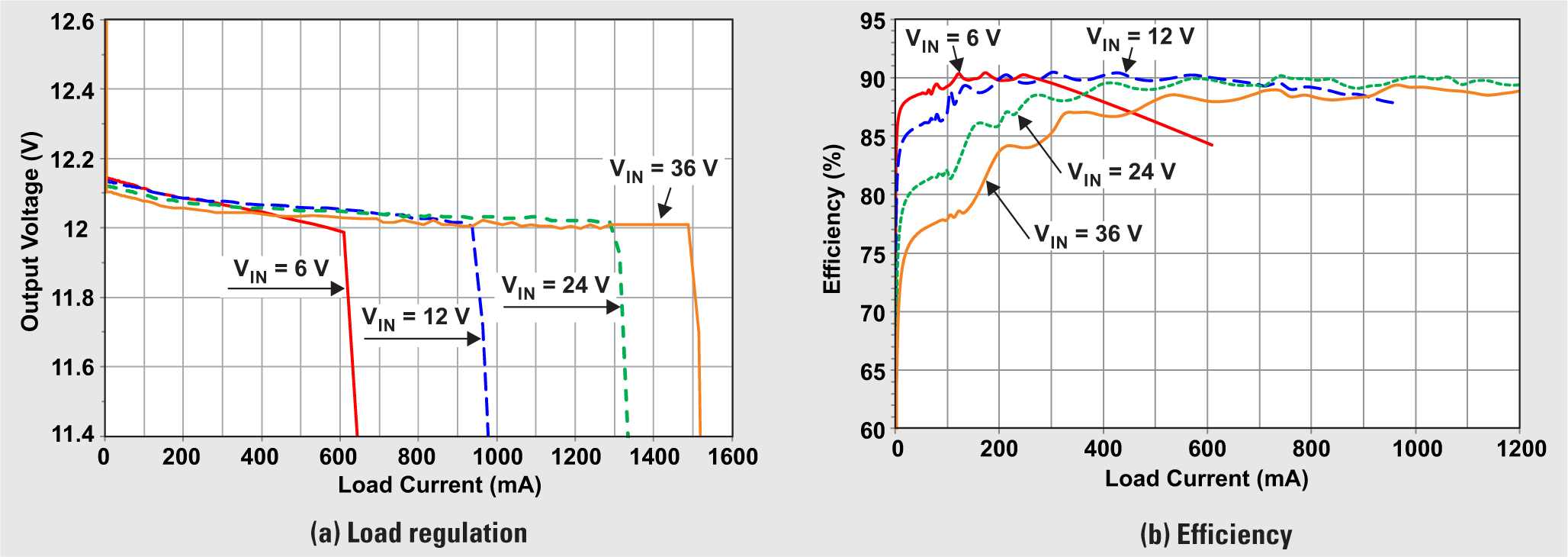

with a 12-V OutputWith nominal design effort, the regulation performance can rival that of conventional opto-isolated solutions without the added solution size, cost and reliability concerns. As a result, this PSR technique supports improved converter performance, higher temperature operation, greater manufacturability and robust protection against fault conditions—important attributes for mHEV applications. Figure 4 presents the load regulation and efficiency curves for several input voltages and a 12-V nominal output.

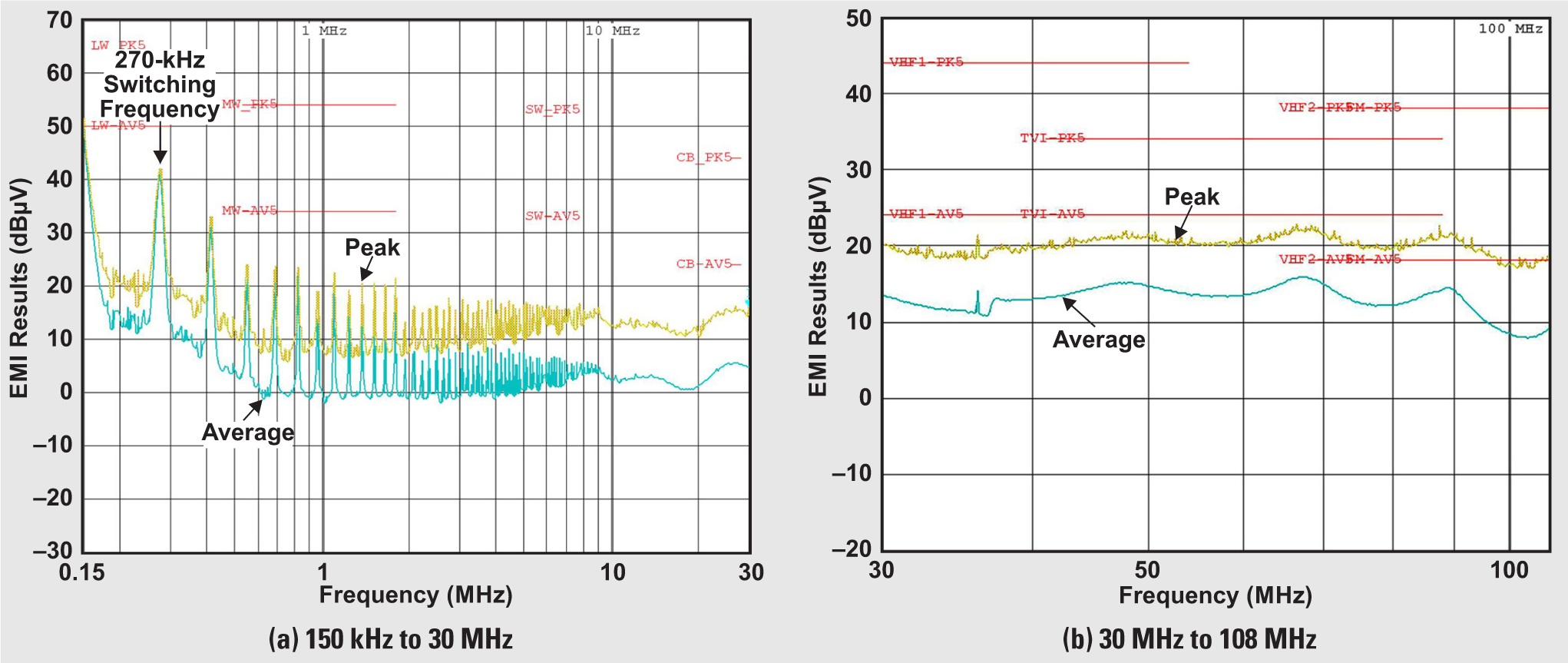

In terms of electromagnetic interference (EMI), the primary-side switch always turns on at zero current, thus avoiding undesirable reverse recovery of the flyback rectifier diode. Moreover, the switch turn-off in BCM is a quasi-resonant soft transition. This supports lower total switching losses and reduced conducted and radiated noise signatures. Figure 5 shows Comité International Spécial des Perturbations Radioélectriques (CISPR) 25 Class 5 conducted EMI results of the flyback converter, with the optional Y-capacitor installed between primary and secondary grounds (as shown in Figure 3a) to reduce the common-node noise signature.

Figure 4 PSR Flyback Converter

Performance with a 12-v Output

Figure 4 PSR Flyback Converter

Performance with a 12-v Output Figure 5 CISPR 25 Class 5 EMI

Measurements of the PSR Flyback Converter (VIN = 13.5 V,

IOUT = 700 Ma)

Figure 5 CISPR 25 Class 5 EMI

Measurements of the PSR Flyback Converter (VIN = 13.5 V,

IOUT = 700 Ma)| PSR Flyback Converter | Input Voltage Range | Peak Switch Current (typ) | Maximum Load Current (1) 1 | |

|---|---|---|---|---|

| VIN = 4.5 V | VIN = 13.5 V | |||

| LM5181-Q1 | 4.5 V to 65 V | 0.75 A | 90 mA | 180 mA |

| LM5180-Q1 | 4.5 V to 65 V | 1.5 A | 180 mA | 360 mA |

| LM25180-Q1 | 4.5 V to 42 V | 1.5 A | 180 mA | 360 mA |

| LM25183-Q1 | 4.5 V to 42 V | 2.5 A | 300 mA | 600 mA |

| LM25184-Q1 | 4.5 V to 42 V | 4.1 A | 500 mA | 1 A |

Table 1 identifies the specifics for a footprint-compatible family of automotive-qualified PSR-flyback converters intended for a range of mHEV isolated power applications. Assuming a 12-V output and a transformer with 1-to-1 turns ratio, the table specifies the maximum load currents at input voltages of 4.5 V and 13.5 V, corresponding to the low-voltage battery transient cold-crank and steady-state operating conditions, respectively.

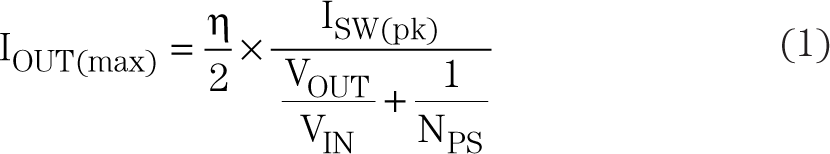

Equation 1 gives the maximum load current of a flyback converter in BCM:

where NPS is the transformer turns ratio, η is the efficiency and ISW(pk) is the switch peak current rating.

The PSR flyback solution is easily scalable by adjusting the transformer[10] and the secondary-side components; the primary-side design remains largely unchanged. Connecting an input clamp circuit[11] allows input voltage swings above 65 V to manage, for example, the transient overvoltage defined in the 48-V automotive specifications[3,4 ] of 70 V for 40 ms.