SNIA053 june 2023 TMP61-Q1

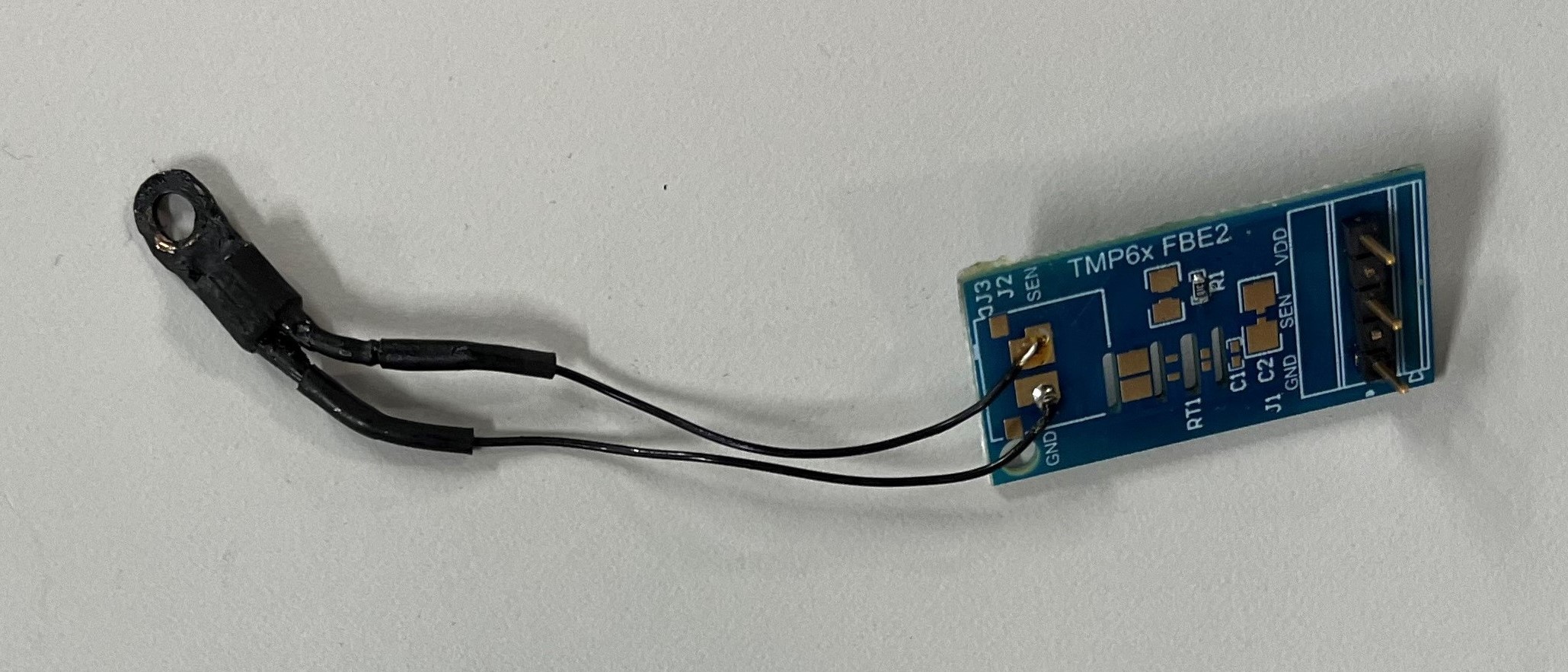

2.5 TMP6 Ring Lug

The TMP61-Q1 is a silicon-based linear thermistor, offering linearity and consistent sensitivity across temperature to enable simple and accurate methods for temperature conversion. The LPG package is a 2-pin through-hole TO-92S package. This package is fit into a JST5.5-S3 ring lug terminal. The LPG packaged TMP61-Q1 is covered with epoxy (MG Chemicals Thermal Epoxy 8329TCM) and wires. Heat-shrink tubing is added to the leads of the device. The specifications of the TMP61-Q1 are as follows: Automotive Q-200 tested, 10 kΩ nominal resistance, 1% resistor tolerance, and –40°C to 170°C operating range.

Figure 2-9 TMP6 Ring Lug With Added Epoxy

and Heat-shrink Tubing

Figure 2-9 TMP6 Ring Lug With Added Epoxy

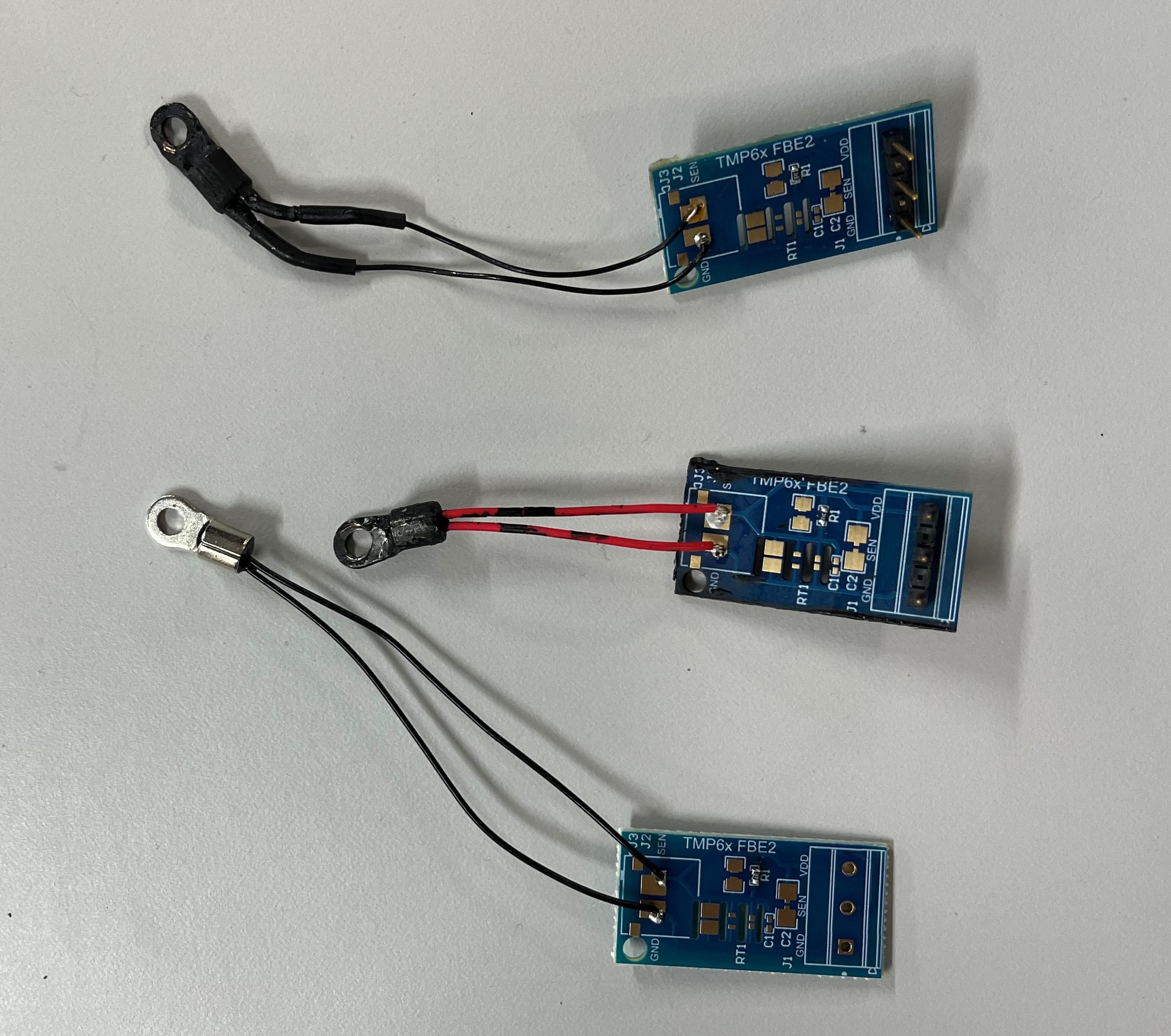

and Heat-shrink TubingAll of the ring lug style thermistors used in this testing are connected to PCB boards that included bias resistors and pins for powering the thermistor as well as measuring the thermistor voltage. The ring lugs are also sprayed with a matte black paint for the purpose of measuring an accurate temperature when using the Fluke TiS60+ Thermal Imager, as shown in Figure 2-10.

Figure 2-10 Ring Lug Thermistor

PCBs

Figure 2-10 Ring Lug Thermistor

PCBs