SPRADC9 july 2023 AM62A1-Q1 , AM62A3 , AM62A7

1.1 Defect Detection Demo Summary

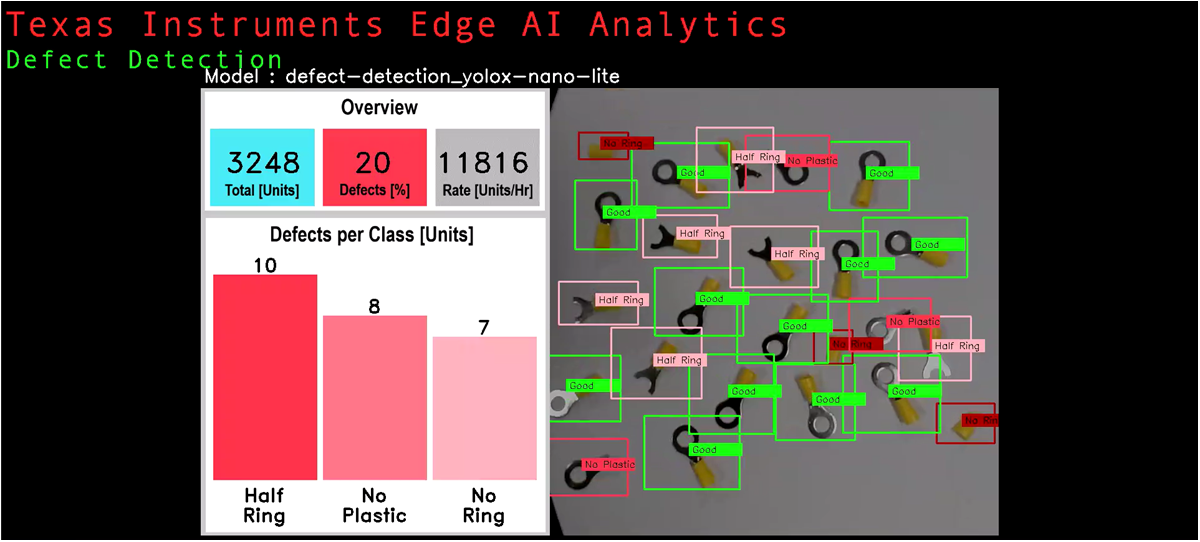

Defect detection is a crucial part of quality assurance in the manufacturing process. This demo uses AM62A to run a vision based artificial intelligence model for defect detection for manufacturing applications. The model tests the produced units as they move on a conveyor belt, to recognize the accepted and the defected units. Figure 1-1 shows a screenshot of the application.

Figure 1-1 Screenshot of the Defect Detection

End Application Using AM62A (Right side is a live video feed with color boxes

marking the detected objects. Left side is a graphical quality control

dashboard.)

Figure 1-1 Screenshot of the Defect Detection

End Application Using AM62A (Right side is a live video feed with color boxes

marking the detected objects. Left side is a graphical quality control

dashboard.)An object tracker is developed for this demo to provide accurate coordinates of the units for sorting and filtering. A live video is displayed on the screen. The units are marked on the screen using green boxes for good (accepted) units while defected units are marked with boxes with different shades of red to distinguish the types of defects. The screen also includes a graphical dashboard showing live statistics about total products, defect percentage, production rate, and a histogram of the types of defect. The object tracker and the graphical dashboard are built using Python. The code base and details of how to run the demo are available on TI marketplace as a Github repo: https://github.com/TexasInstruments/edgeai-gst-apps-defect-detection.

The steps followed to develop this application includes:

- Data collection and preparation

- Model selection, training, and compilation

- Model evaluation and deployment

- Application code development including object tracker and graphical dashboard

- System performance analysis and power consumption estimation