SPRADC9 july 2023 AM62A1-Q1 , AM62A3 , AM62A7

2.1 Test Samples

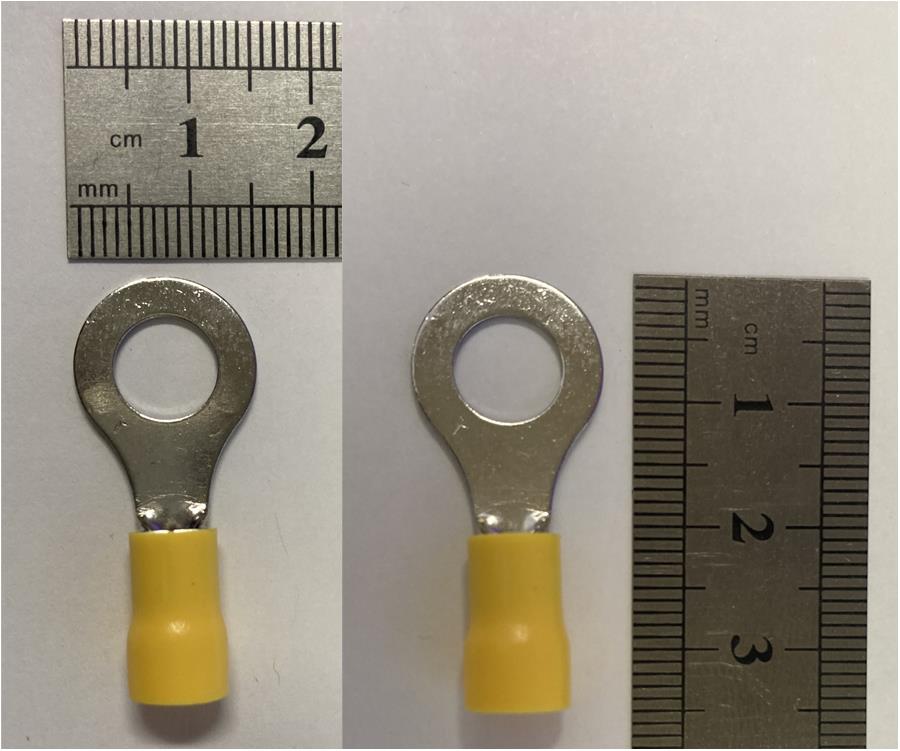

Insulated Ring Crimp Terminals Connectors are used as samples for the defect detection application. Figure 2-1 shows pictures of the samples with measuring rulers as a reference. The industrial size of the terminals is M8 12-10 AWG with yellow cap. The actual dimensions are:

- Length ~= 34 mm

- Metal circle external diameter ~= 15 mm

- Plastic cap diameter ~= 8 mm

Figure 2-1 Tests Samples Used for the

Defect Detection Demo, Ring Crimp Terminals Connectors

Figure 2-1 Tests Samples Used for the

Defect Detection Demo, Ring Crimp Terminals ConnectorsThese objects have several appealing characteristics for an AI based defect detection demo to show its capability compared to conventional rules-based machine vision algorithm. The small size allows including tens of pieces in one frame to show application’s capability to detect and track high number of objects. The two types of materials in the objects provide more options to generate artificial defects for demonstration purposes. The shiny metal part looks different depending on the lighting condition which show system capacities to work with challenging to detect objects.

The yolox-nano-lite is used in this demo and it can be trained for more classes.