SPRUHJ0C April 2013 – October 2021 TMS320F28068M , TMS320F28069-Q1 , TMS320F28069M , TMS320F28069M-Q1

CONTROL

SpinTAC Control is an advanced speed and position controller featuring Active Disturbance Rejection Control (ADRC), which proactively estimates and compensates for system disturbance, in real-time. SpinTAC automatically compensates for undesired system behavior caused by:

- Uncertainties (for example, resonant mode)

- Nonlinear friction

- Changing loads

- Environmental changes.

SpinTAC Control presents better disturbance rejection and trajectory tracking performance than a PI controller, and can tolerate a wide range of inertia change. This means that SpinTAC improves accuracy and system performance, and minimizes mechanical system duress.

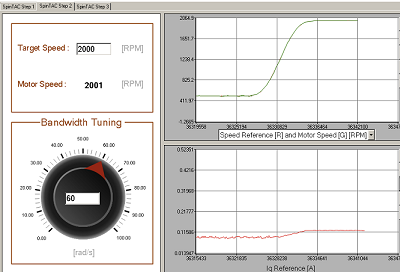

With single coefficient tuning, the SpinTAC controller allows users to quickly test and tune their velocity and position control from soft to stiff response. This single gain (bandwidth) typically works across the entire variable speed, position and load range of an application, reducing complexity and system tuning time typical in multi-variable PI-based systems. A single parameter controls both position and speed. These systems often require a dozen or more tuned coefficient sets to handle all possible dynamic conditions.

The InstaSPIN-MOTION (F2806xM) graphical user interface (GUI) (see Figure 3-2), in conjunction with the InstaSPIN-MOTION Quick Start Guide, allows users to quickly evaluate InstaSPIN-MOTION (speed control) using TI's evaluation kits and the TI provided motors, or their own motor. The GUI is designed to quickly guide you through the InstaSPIN-MOTION evaluation process. You can obtain the GUI, free of charge, from Motor Kit Application Software for TMDSCNCD28069MISO controlCARDs. Once you determine that InstaSPIN-MOTION is right for your application, use the MotorWare™-based projects, in conjunction with the InstaSPIN-FOC and InstaSPIN-MOTION User's Guide to design your project and conduct performance testing.

Figure 2-2 Simple

Tuning Interface

Figure 2-2 Simple

Tuning Interface