SSZT274 july 2020 LP8866-Q1

High resolution and seamless operation are important for larger automotive display screens, shown in Figure 1, as consumers want a clear picture with smooth functionality. Given the harsh environments in vehicles, system reliability and safety are also concerns. As a result, it’s a challenge for designers to find a backlight LED solution that’s designed for larger screens while also providing a high dimming ratio and ensuring system safety.

Figure 1 Automotive display with an LCD

screen

Figure 1 Automotive display with an LCD

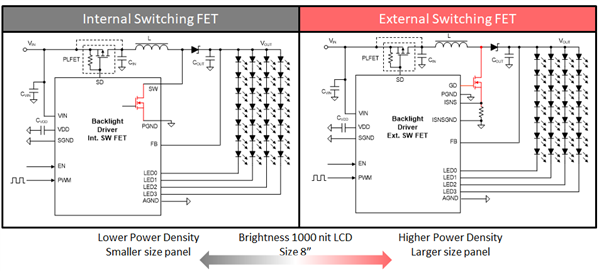

screenTo drive larger display screens, backlight LED drivers must have a high boost voltage and high current sink. Typically, automotive displays need to be greater than 1000 nits, which requires more LEDs or brighter, higher-current LEDs to achieve this level of brightness. Using more LEDs leads to higher boost voltage, while using stronger LEDs leads to more current. Using an external switching field effect transistor (FET), shown in Figure 2, will provide higher power density to manage a larger-sized panel. Additionally, with an external FET, the power dissipation is spread further from the IC, enabling the thermal rise to be lower. A multichannel driver with a high current low-side current sink is also necessary to drive uniformity of display across the different channels.

TI’s six-channel LP8866-Q1 automotive backlight driver maximizes power density and features an external switching FET. The device, designed for applications such as infotainment systems and head-up displays, offers a current sink as high as 200 mA. A high current sink is beneficial to ensure you will always have sufficient levels of brightness in your display – making it easy to read even on the sunniest days.

Figure 2 Automotive backlight LED

driver topology

Figure 2 Automotive backlight LED

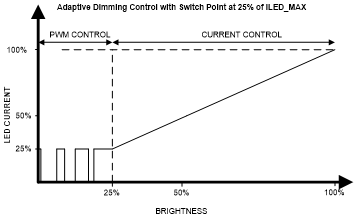

driver topologyTo achieve a smooth transition of brightness over a wide range, pulse width modulation (PWM) dimming is necessary and should have high resolution – especially in low-light situations. In bright conditions, analog dimming would be a better choice in order to avoid boost output ripple and audible noise issues.

TI uses an adaptive dimming control solution, known as hybrid dimming, illustrated in Figure 3. The LP8866-Q1 can begin dimming with 12-bit current digital-to-analog converter steps from 100% (0xFFFF) to 12.5% (0x2000) input brightness. Below 12.5% brightness, up to 16-bit PWM resolution can be achieved with the device (PWM duty control plus dither control). The benefits of hybrid dimming include reduced electromagnetic interference, lower boost output ripple and audible noise, improved LED optical efficiency, and an increased dimming resolution ratio for a given LED PWM frequency.

Figure 3 Hybrid dimming mode

Figure 3 Hybrid dimming modeAdditional resources

- Check out these training videos about analog dimming and PWM dimming methods.

- Start your design today with the LP8866-Q1 evaluation module.