SSZT362 december 2019

Modern factories and other industrial settings consist of a rich mesh of interconnected machines that themselves include devices such as networked computers, programmable logic controllers, input/output cards, field transmitters, sensors, and a collection of wired and wireless communications networks. The amount of data generated and communicated within factory environments has increased dramatically in the last few years, as companies race to monetize the efficiencies and agility that smart factories bring.

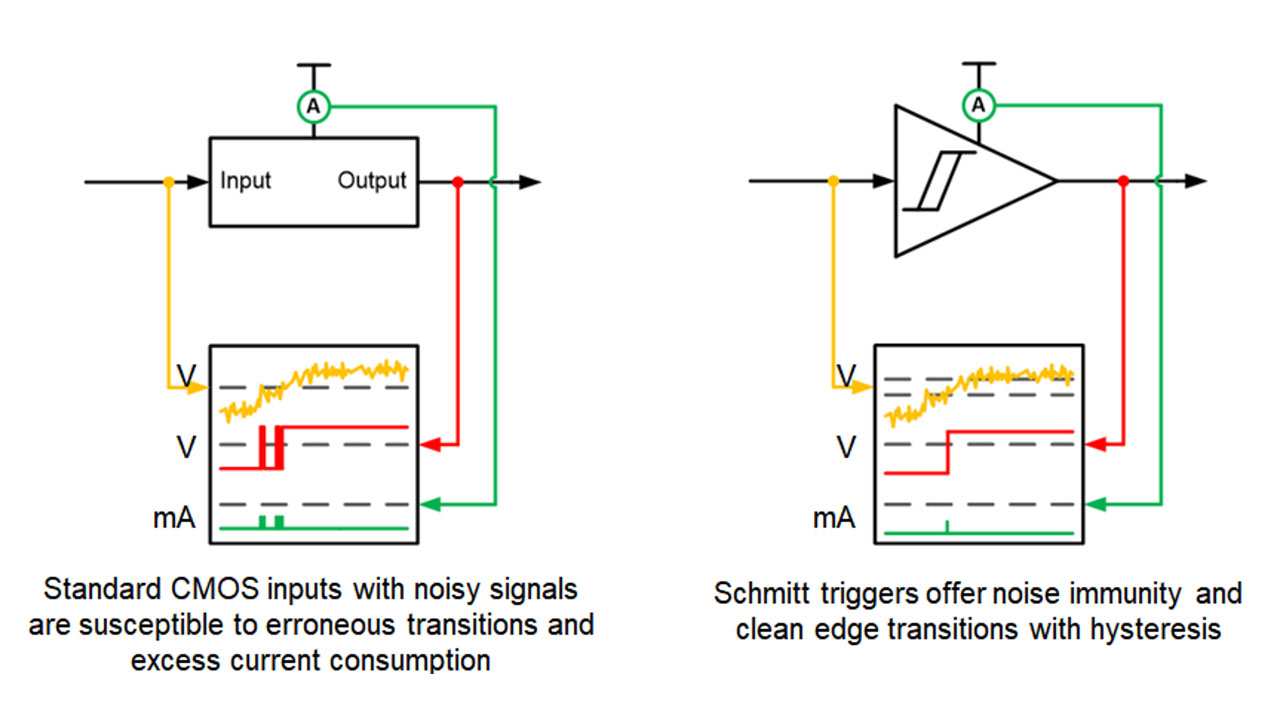

However, connecting factory equipment has unique challenges. One of these challenges is the vast array of electrical noise generated by factory equipment such as motors, switching power supplies, high-voltage distribution cables and other similar sources. A variety of system impairments such as bit errors, signal degradation, signal amplification, signal loss or a combination of these will generate electrical noise, ultimately resulting in system malfunctions that range from unnoticeable bit glitches to catastrophic system failures that could endanger lives or result in the processing of unusable goods.

Industrial system designers must pay special attention to the impact that noise from a factory environment can have on the robustness of their design and create layers of noise protection; for example, implementing system circuit designs that are noise-tolerant in case noise makes its way into a system’s circuits.

Multiple design techniques exist to mitigate and overcome this type of electrical noise; all engineers should use building-block devices like logic circuits, which have a higher level of noise immunity. Logic circuits play a critical role in bringing a system’s circuit components together, and as such act as gateways for control and data signals of a system’s circuit implementations. Using logic devices with higher noise immunity basically means stopping noise at these gateways before it can propagate through a system.

One critical feature of logic devices that helps improve noise immunity is Schmitt-trigger inputs. Standard complementary metal-oxide semiconductor (CMOS) inputs are susceptible to noise: noisy inputs can cross the input threshold multiple times, causing oscillations at the output (as illustrated in Figure 1), potentially resulting in system errors. In contrast, a Schmitt-trigger input design separates the positive and negative-going thresholds.

Figure 1 Standard CMOS inputs vs.

Schmitt-trigger inputs

Figure 1 Standard CMOS inputs vs.

Schmitt-trigger inputsLogic circuits with Schmitt-trigger inputs have outputs that will switch only once; they will also have clean signal edges for any CMOS input (see this Schmitt-trigger video, “Eliminate slow or noisy input signals,” for a detailed explanation). Given the importance of using logic building-block devices with Schmitt-trigger inputs for noisy industrial applications, logic device selection becomes an important step.

TI’s HCS logic family makes the logic selection process easy for industrial applications by providing a portfolio where every logic device includes Schmitt-trigger inputs. Encompassing all major logic function types, the HCS family enables industrial system designers to confidently implement noise-tolerant and robust system control and data logic interfaces.

Additional resources

- Learn more about TI’s HCS logic family.

- Watch “The Logic Minute – Logic and Translation” video series.