SSZT492 April 2019 BQ27421-G1 , BQ27426 , BQ27Z561-R1 , BQ2970 , BQ2971 , BQ2972 , BQ2973

A high or a low blood glucose level in the body can cause serious health threats, so it makes monitoring glucose levels a high priority. And with more than 150 million people around the world with diabetes, the need for personal portable blood glucose monitors (BGMs) is great.

A continuous glucose monitor (CGM), shown in Figure 1, enables people with diabetes to check glucose readings in real time, or monitor glucose readings over an extended period of time. As the name implies, CGMs continuously monitor glucose levels and alert users of dangerous highs or lows. The monitor typically consists of a sensor unit, shown in Figure 2, and an aggregator unit, shown in Figure 3.

Figure 1 A Cgm

Figure 1 A CgmThe sensor unit connects to the body for a certain time period (eight to ten days, for instance). It uses a primary button-cell or coin-cell battery. The aggregator unit is a battery-powered handheld unit that harnesses radio-frequency (RF) technology such as Near Field Communication to read the glucose data. The battery-management subsystem of the aggregator unit comprises a battery charger, gauge and protection. A typical aggregator unit operates from a 3.7-V lithium-ion single-cell battery. It is rechargeable with either a USB or DC input from an adapter.

Figure 2 A CGM Sensor Unit

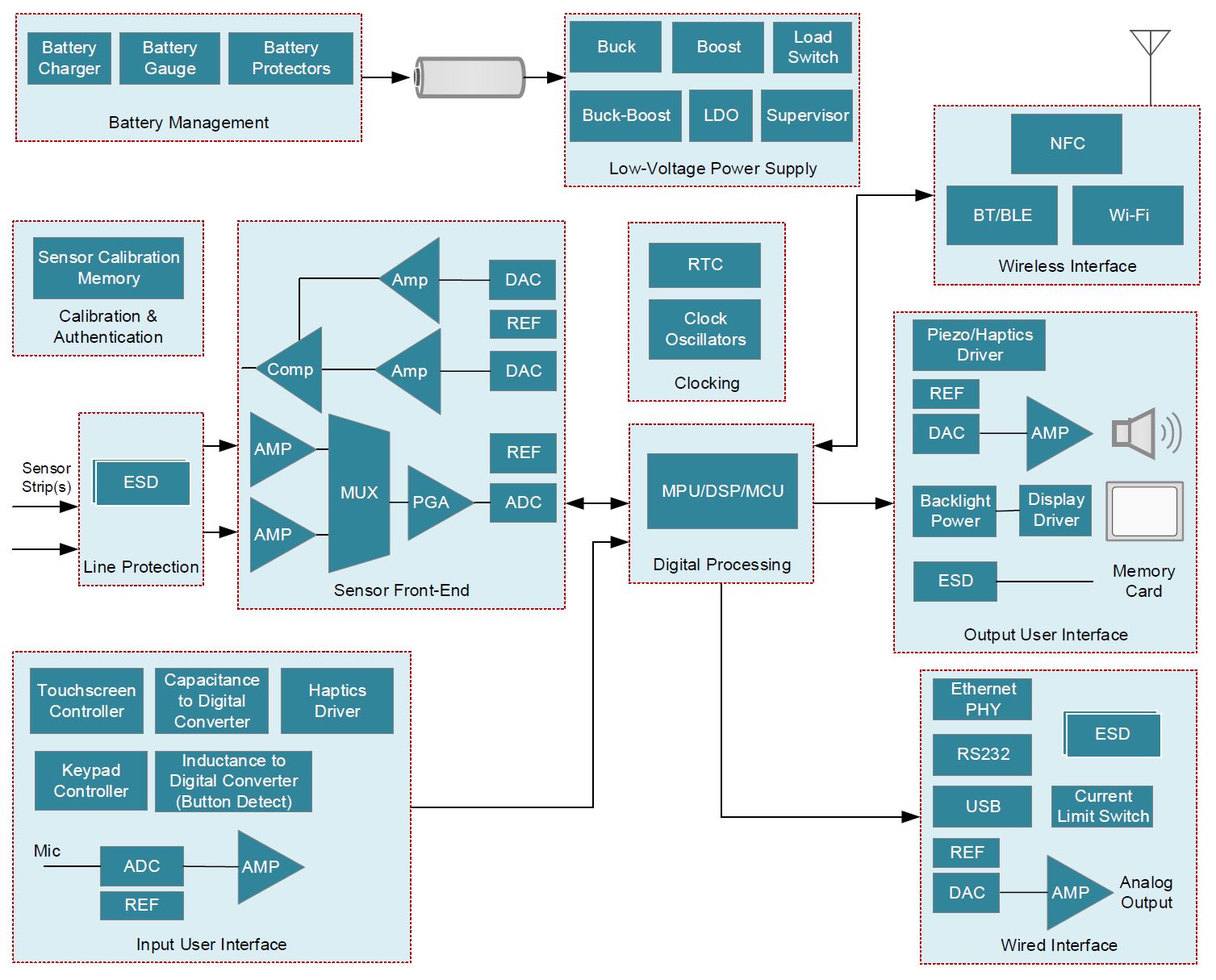

Figure 2 A CGM Sensor Unit Figure 3 Block Diagram of a CGM

Aggregator Unit

Figure 3 Block Diagram of a CGM

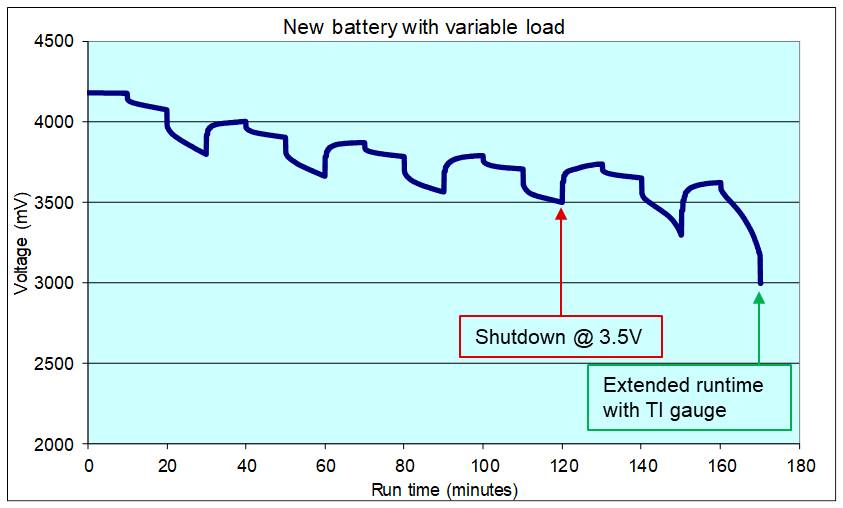

Aggregator UnitBattery gauges help address critical battery-management problems by using predictive methods to estimate remaining battery capacity, state of charge, time to empty and state of health under various load conditions. By having intelligent battery gauging, you can extend the run time (as seen in Figure 4) and cycle life of the battery. TI’s Impedance Track™ gauging algorithm enables battery capacity predictability with >99% accuracy, and our battery gauges have superior analog measurement performance and battery characteristic modeling.

Figure 4 Extended Run Time with a TI

Gauge

Figure 4 Extended Run Time with a TI

GaugeThere are several single-cell gauging options that are compact, cost-effective and offer ultra-low power consumption. The fuel gauge can reside in the battery pack or system PCB, with the latter more common in portable medical applications.

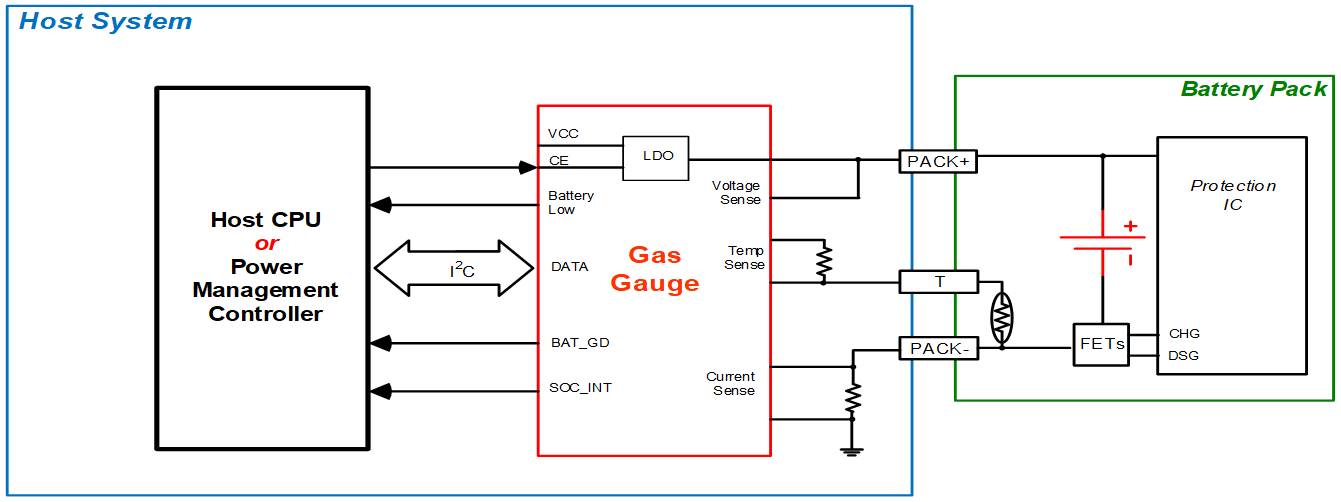

Figure 5 and Figure 6 show typical system-side and pack-side gas-gauging configurations. Gauges on the system PCB such as the BQ27426 require minimal user configuration and consume little current during normal operation. For a higher level of integration, some gauges have an integrated sense resistor, like the BQ27421-G1.

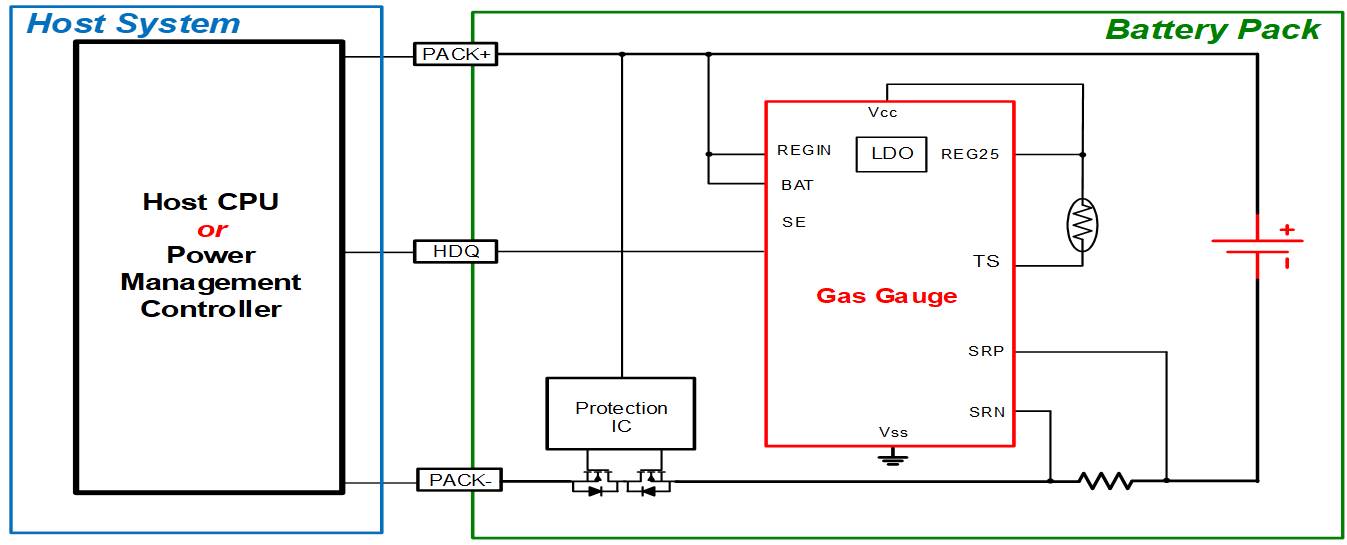

On the other hand, if the gauge is designed into the battery pack, there are highly accurate options using flash-based firmware and integrated Secure Hash Algorithm-256 authentication, such as the BQ27Z561-R1. Protection integrated circuits, such as the BQ2970, can provide voltage, current and reverse charger protection.

Figure 5 Typical Host/system-side

Gas-gauging Configuration

Figure 5 Typical Host/system-side

Gas-gauging Configuration Figure 6 Typical Pack-side

Gas-gauging Configuration

Figure 6 Typical Pack-side

Gas-gauging ConfigurationBattery gauges bring an increased level of sophistication and intelligence to power management. Systems without accurate gauges simply shut down at a fixed voltage. Many devices shut down at 3.5 V in order to cover worst-case reserve capacity (reserving battery energy for shutdown tasks), but as Figure 4 shows, simply measuring the battery voltage with a microcontroller and analog-to-digital converter to generate a low-battery warning is not a reliable method of gauging the remaining capacity, since most applications have variable load conditions. A battery gauge will compute the remaining capacity and alter the shutdown voltage to meet the reserve capacity under all conditions, in this case leading to increased run time.

In addition to the advantage of reserve capacity, some battery gauges have the ability to not report a 0% state of charge due to a high transient pulsed load from the application, causing the cell voltage to dip below the termination voltage. This is beneficial in cases where there is still significant capacity in the battery, but the high transient causes the termination voltage to be reached prematurely.

Batteries are complex electrochemical systems that are affected by battery aging, temperature and impedance. Algorithms, compact devices and advanced device integration are all key features in improving system performance. What are your biggest challenges in medical battery-operated applications like continuous blood glucose monitors? Tell us in the comments.

Additional Resources

- Explore TI’s battery gauge portfolio.

- Check out resources for blood glucose monitors.

- Watch our “Battery Management Deep Dive On-Demand Technical Training.”

- Read more blog posts about this topic: