SSZT703 may 2018 LM71-Q1 , LMT01-Q1

The automotive industry is rapidly introducing new technologies as automotive manufacturers seek to provide consumers vehicles with improved convenience, comfort, performance and fuel economy. The most visible technology innovations are often in the vehicle cabin and part of the infotainment system, but there have also been great improvements in automotive powertrains that improve vehicle handling, performance and fuel economy.

Today, one of the most common powertrain choices consumers will need to make is whether to purchase a vehicle with a manual or automatic transmission. Driving enthusiasts tend to prefer manual transmissions, but automatic transmissions have become popular due to their convenience. The automatic transmission is a large complex system that requires on-board processing capabilities and needs to remain operational under all driving conditions.

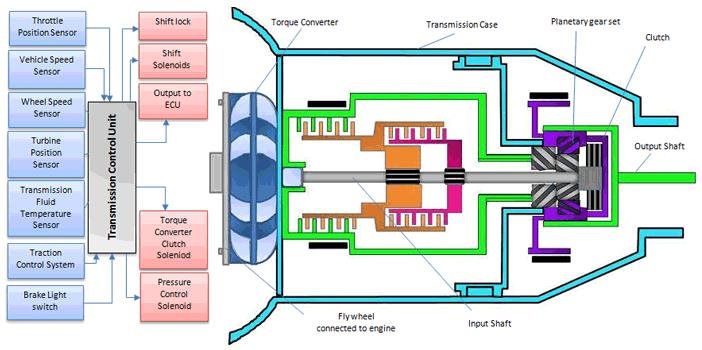

An automatic transmission operates by taking power generated by the vehicle’s engine and channeling it through different gear ratios based on driving demands. The purpose of the various gears is to ensure that the engine’s revolutions per minute (RPM) and torque being supplied to the wheels are matched to the vehicle’s current speed and acceleration. Power from the engine flywheel transfers to the transmission through the torque converter (see Figure 1).

Figure 1 Automatic Transmission

Overview

Figure 1 Automatic Transmission

OverviewThe transmission control unit (TCU) is an advanced control system that manages gear shifting based on speed, position, pressure and temperature data reported from the transmission case. Based on the required connection to the engine, both the TCU and transmission case are located in or near the engine compartment. But the extreme temperatures reached in the engine compartment can create a risk that either will be damaged.

The TCU module contains a board with many integrated circuit components, including microcontrollers (MCUs) that are sensitive to high temperatures. Many MCUs have some form of integrated temperature-sensing capabilities, but they are usually inaccurate and poorly approximate the overall temperature of a TCU module.

The LM71-Q1 is an external temperature sensor that can communicate temperature directly to the MCU over Serial Peripheral Interface (SPI), removing the need for an analog-to-digital converter channel and/or lookup table. Additionally, the LM71-Q1 can monitor the temperature of the overall TCU module with an accuracy of +3/-2°C for -40°C and +150°C.

As previously mentioned, the TCU uses temperature data from the transmission case as part of its decision-making process. The LMT01-Q1 is an easy-to-use digital temperature sensor in a leaded two-pin package that you can mount to the transmission case. You can crimp wires to the LMT01-Q1 package leads and connect those wires to the TCU board. The LMT01-Q1 communicates temperature by sending out pulses counted by the MCU/processor.

An advantage of the LMT01-Q1 is its always-on pulse train, which means that there will be a clear sign if the device fails and is no longer measuring/communicating temperature. The automotive-qualified LMT01-Q1 can monitor transmission case temperatures with an accuracy of ±0.75°C between -40°C and +150°C.

Automatic transmissions are great innovations that increase fuel economy by optimizing gear ratios and improving the overall driver experience. Ensuring proper automatic transmission operation requires close monitoring of the temperature of the automatic transmission case and TCU. TI offers several easy-to-use solutions to help you implement a complete thermal-management strategy.

Additional Resources

- Explore the Automotive High Temperature Sensor (HTS) Reference Design.

- Check out TI’s temperature sensor portfolio.

- Visit the learning center to learn more about designing with temperature sensors.

- Learn more about TI’s powertrain solutions.