SSZT809 february 2018 UCC28880 , UCC28881

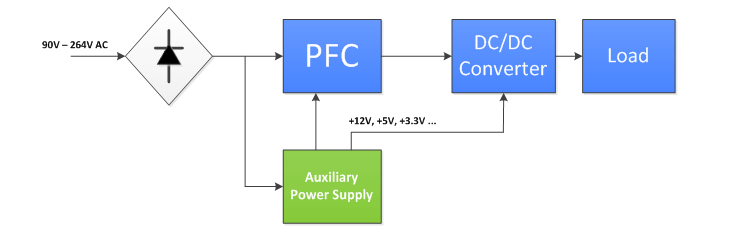

High-power converters used in major appliances, power tools and industrial systems need auxiliary power supplies to support the housekeeping needs of the whole system. An auxiliary power supply usually powers the internal controller, sensing electronics for voltage and current feedback and power blocks in the system. Figure 1 shows a typical auxiliary power supply.

Figure 1 System Block Diagram of a

High-power Converter

Figure 1 System Block Diagram of a

High-power ConverterAuxiliary power supplies are independent isolated or non-isolated DC/DC converters as power converters have an electromagnetic interference (EMI) filter, a diode bridge rectifier and a bulk capacitor present in the system, generating a rectified DC bus. These operate over a universal input range from 90V to 264VAC and keep system electronics powered under all conditions to detect faults such as undervoltage, overvoltage and overcurrent. Typically, auxiliary power supplies generate three or more outputs, delivering power of 10 - 60 watts.

The key challenges of an appliance auxiliary power supply are how to provide safe and reliable power while delivering high performance with low power consumption and low bill-of-materials (BOM) cost.

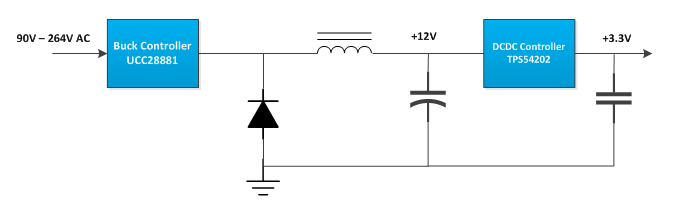

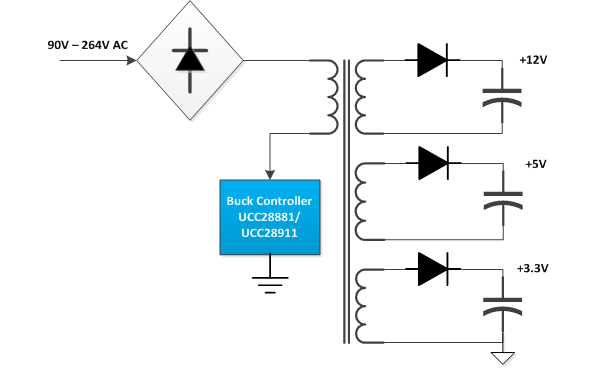

In appliance applications, an auxiliary power supply will need multiple outputs for different loads – +3.3V or +5V for the controller and sensor elements, +12V for the relay and the metal-oxide semiconductor field-effect transistor (MOSFET) driver, and +15V for the insulated gate bipolar transistor (IGBT) module. A high-voltage buck plus DC/DC converter topology and the flyback topology (shown in Figure 2 and Figure 3, respectively) are the two most common topologies.

Figure 2 Block Diagram of a

High-voltage Buck Converter

Figure 2 Block Diagram of a

High-voltage Buck Converter Figure 3 Block Diagram of a Flyback

Converter

Figure 3 Block Diagram of a Flyback

ConverterA high-voltage buck plus DC/DC converter has higher efficiency, higher output-voltage accuracy and fewer external components, while a flyback topology makes it easier to implement multiple outputs and reinforced insulation. You need to decide which topology is more suitable for your system requirements.

TI’s UCC28881 controller can support both topologies. It has a built-in high-voltage startup FET, a 700V power FET and primary current sensing, which aids in reduced component count. Low quiescent power consumption and robust protection for faults make it a good fit for most designs.

The UCC28881 integrates the controller and 700V power MOSFET into one monolithic device. The device also integrates a high-voltage current source, enabling startup and operation directly from the rectified mains voltage. The low quiescent current (IQ) of the device enables excellent efficiency.

The UCC28881 incorporates a soft-start feature for controlled startup of the power stage, which minimizes stress on the power-stage components. The UCC28880 is a low-current version of the UCC28881.

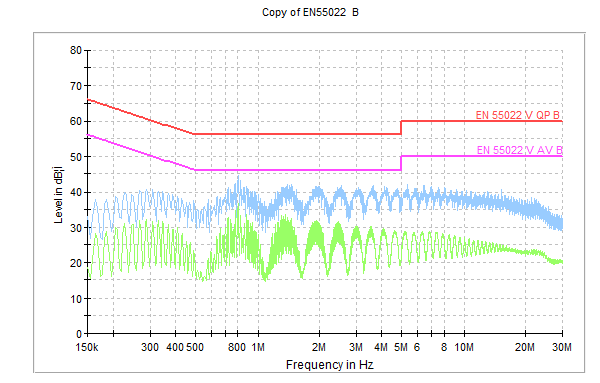

The 3W Non-ISO Bias Power Supply with Up to 80% Efficiency, 15dB Margin EMI Performance Reference Design uses a high-side, high-voltage buck plus DC/DC converter to implement a two-output power supply. It has only eight external components in the AC/DC portion with excellent EMI performance and full protection. Figure 4 shows the EMI test result of European Standard (EN) 55022 Class B. As you can see, there is at least 15dB of margin throughout the entire frequency spectrum.

Figure 4 EMI Performance of the 15dB

Margin EMI Performance Reference Design

Figure 4 EMI Performance of the 15dB

Margin EMI Performance Reference Designauxiliary power supply is a cost-sensitive component in appliance applications, with many design challenges. Given the trade-offs when trying to achieve high efficiency, high power density and high reliability while controlling EMI, you must carefully choose the right topology to achieve the best performance.

Additional Resources

- Get the latest insights from our experts for your smart appliance design.

- Find what you need to make your next-generation appliance design happen.