SSZTA93 april 2017 DRV8908-Q1 , DRV8910-Q1 , DRV8912-Q1

Whether it’s hot or cold outside, passengers inside a car are comfortable thanks to automotive heating and cooling systems. These heating, ventilation and air conditioning (HVAC) systems vary in complexity and level of automation depending on the vehicle class. While an economy car requires that a driver manually turn knobs to control the temperature, a higher-end vehicle uses sensors to automatically control not only the temperature but also the humidity and quality of air inside the cabin.

Moving the Air

The number of ways that the air can flow is remarkable: from outside to the evaporator to the windshield, or from inside to the heat exchanger to the vent in the footwell. So how does an HVAC system control which way the air goes?

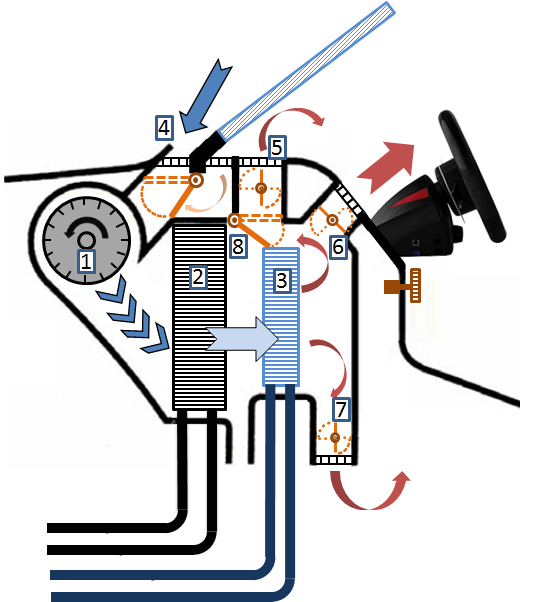

Figure 1 is a side view of an HVAC system. Numbers mark the key components, while arrows show the direction of air distribution. Components 4 through 8 in Figure 1 show the flap actuators. The orange dotted lines represent the area where the flaps are moving, and the solid orange lines represent the flaps. The number of flap actuators in an HVAC system depends on the overall complexity of the system – if it has single or multiple-zone HVACs.

Figure 1 A Car HVAC with Eight Components: 1 = Blower, 2 = Evaporator, 3 = Heater, 4 = Intake Air Flap, 5, 6 and 7 = Air-distribution Flap, 8 = Air-mixing Flap

Figure 1 A Car HVAC with Eight Components: 1 = Blower, 2 = Evaporator, 3 = Heater, 4 = Intake Air Flap, 5, 6 and 7 = Air-distribution Flap, 8 = Air-mixing FlapFlap Actuators

- Intake air-flap actuator (component 4 in Figure 1): This flap actuator controls whether the source of air for conditioning will be outside air or recirculated cabin air. This flap actuator position is controllable by the driver using the recirculate button, or by the HVAC system using data from in-cabin air-quality sensors.

- Air-mixing flap actuator (component 8 in Figure 1): This flap actuator mixes the warm (heat exchanger) and cool (evaporator) air in order to achieve the desired air temperature.

- Air distribution flap actuator (components 5, 6 and 7 in Figure 1): These flap actuators, which could vary in number based on the vehicle class, distribute the air inside the cabin.

DC Motor

More Choices

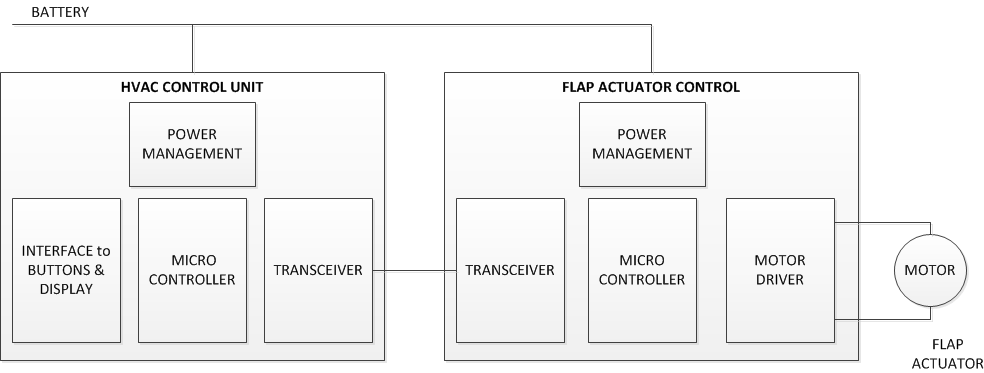

Figure 2 Remote Control of Flap Actuator Motor

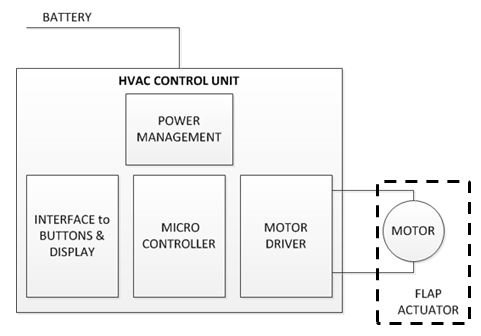

Figure 2 Remote Control of Flap Actuator Motor Figure 3 Integrated Motor Driver for Flap Actuator

Figure 3 Integrated Motor Driver for Flap ActuatorEven More Choices

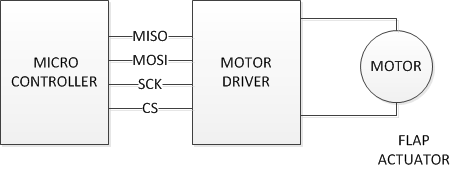

Figure 4 A Microcontroller Communicating with the Motor Driver Using SPI

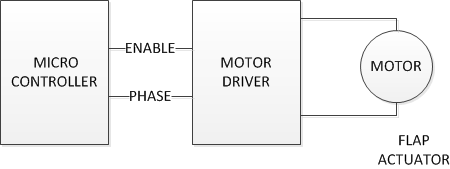

Figure 4 A Microcontroller Communicating with the Motor Driver Using SPI Figure 5 A Microcontroller Controlling the Motor Driver Directly

Figure 5 A Microcontroller Controlling the Motor Driver DirectlyKeeping It Simple

Additional Resources to Help You Design Automotive HVAC Subsystems:

- Learn how to connect and control multiple flap motors with the automotive HVAC control reference design with HMI.

- For DC motor designs, check out the automotive 12V 200W (20A) BLDC motor drive reference design and the automotive 2-axis power seat brushed DC motor drive reference design.

- Check out TI’s body electronics and lighting portal for more related reference designs.