TIDUES0E June 2019 – April 2024 TMS320F28P550SG , TMS320F28P550SJ , TMS320F28P559SG-Q1 , TMS320F28P559SJ-Q1

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

- 3Circuit Description

- 4Hardware, Software, Testing Requirements, and Test Results

- 5Design Files

- 6Related Documentation

- 7Terminology

- 8About the Author

- 9Revision History

4.4.7 Lab 7

In this setup, the DC source is connected to secondary side and the resistive load is connected to primary side. The design is operated with closed-current loop in the reverse direction.

Compile the project by selecting 7: Closed Loop Current with Resistive Load, Sec to Prim Power Flow in the drop-down menu of Project Options from PowerSUITE GUI. Make sure current and voltage limits are set per operating conditions.

#if DAB_LAB == 7

#define DAB_CONTROL_RUNNING_ON C28X_CORE

#define DAB_POWER_FLOW DAB_POWER_FLOW_SEC_PRI

#define DAB_INCR_BUILD DAB_CLOSED_LOOP_BUILD

#define DAB_TEST_SETUP DAB_TEST_SETUP_RES_LOAD

#define DAB_PROTECTION DAB_PROTECTION_ENABLED

#define DAB_CONTROL_MODE DAB_CURRENT_MODE

#define DAB_SFRA_TYPE 1

#define DAB_SFRA_AMPLITUDE (float32_t)DAB_SFRA_INJECTION_AMPLITUDE_LEVEL1

#endif- Test Setup for Lab 7 (Closed Current

Loop - Iprim - Reverse power flow)

- Run the project by clicking the green run button in CCS.

- Populate the required variables in

the watch window by loading JavaScript

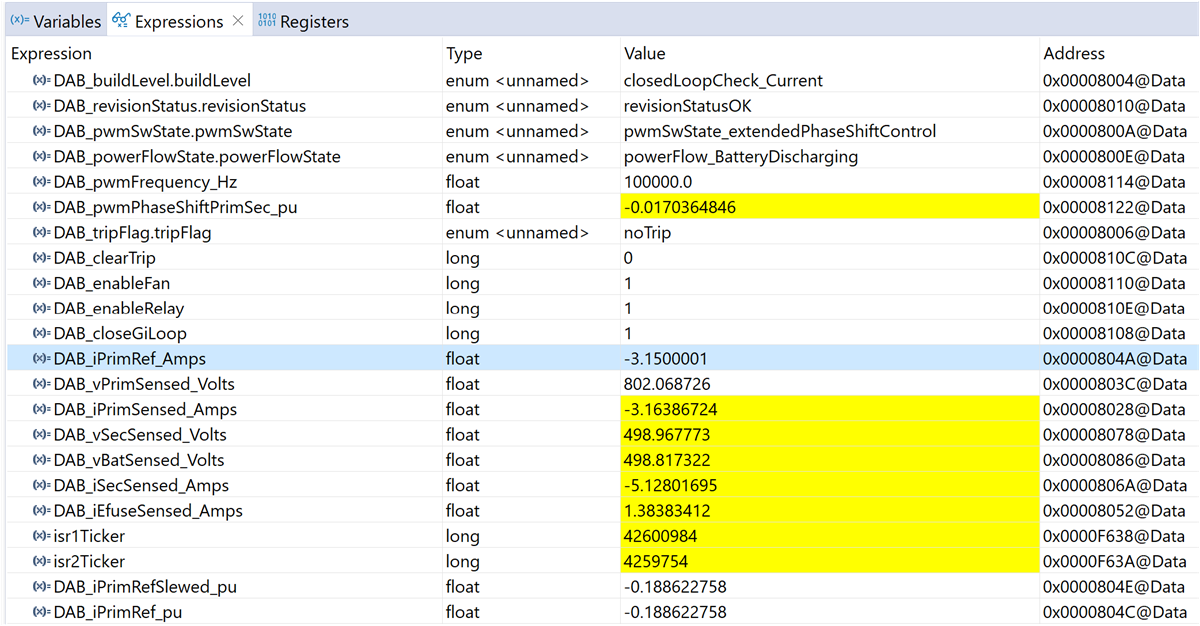

setupdebugenv_lab7.jsin the scripting console. Figure 4-48 Lab 7 - Watch View

Figure 4-48 Lab 7 - Watch View - Enable fans and relays by writing "1"

into

DAB_enableFanandDAB_enableRelay. - Enable PWM by writing “1” to the

DAB_clearTripvariable in the watch view. - Check if the

DAB_vPrimSensed_Volts,DAB_iPrimSensed_Amps,DAB_vSecSensed_Volts, andDAB_iSecSensed_Ampsvariables are updating periodically. - Set the output voltage by writing to

DAB_iPrimRef_Volts(in this example –3 A). - Enable closed loop operation by

writing “1” to the

DAB_closeGvLoopvariable. The controller automatically adjusts the phase shift , depending upon the operating conditions to generate primary output current to match with that ofDAB_iPrimRef_Volts. - Now the secondary side voltage and

DAB_iPrimRef_Voltscan be increased in steps and the control behavior can be observed.

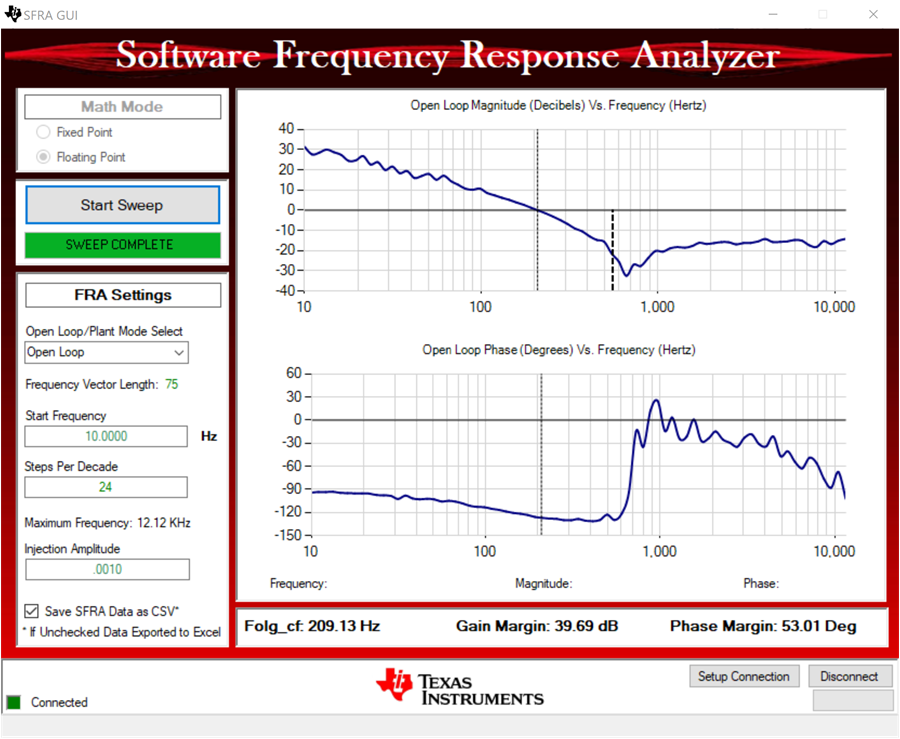

- Frequency response of closed loop

current

- Follow the same steps as in Lab 4.

Test Condition: VIN = 350 V, VOUT = 550 V, IOUT = 9 A.Figure 4-49 Lab 7 - SFRA Open Loop Plot for the Closed Current Loop With Reverse Power Flow

Test Condition: VIN = 350 V, VOUT = 550 V, IOUT = 9 A.Figure 4-49 Lab 7 - SFRA Open Loop Plot for the Closed Current Loop With Reverse Power Flow

VIN refers to secondary side voltage, VOUT and IOUT refer to primary side voltage and current in reverse direction (DAB_IprimSensed_Amps = –9 A).The same controller and gains as in Lab 4 are used.

- Follow the same steps as in Lab 4.