TIDUF60 December 2023

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

-

2System Overview

- 2.1 Block Diagram

- 2.2 Design Considerations

- 2.3 Highlighted Products

- 2.4 System Design Theory

-

3Hardware, Software, Testing Requirements, and Test Results

- 3.1 Getting Started Hardware

- 3.2 Getting Started GUI

- 3.3

Getting Started C2000 Firmware

- 3.3.1 Download and Install Software Required for Board Test

- 3.3.2 Opening Project Inside CCS

- 3.3.3 Project Structure

- 3.3.4 Test Procedure

- 3.4 Test Results

- 3.5 Migrate Firmware to a New Hardware Board

- 3.6 Getting Started MSPM0 Firmware

- 4Design and Documentation Support

- 5About the Author

3.3.4.3.4 Run the Code

To run the code, complete the following steps:

- Set the AC source output to 0 V at 50/60 Hz, turn on the AC power supply, slowly increase the input voltage from 0-V to 220-V AC.

- Run the project by clicking the

button, or click Run → Resume in the Debug tab. Set systemVars.flagEnableSystem to "1" after a fixed time, that means the offsets calibration has been done and the power relay for inrush is turned on. The motor fault flags for motorVars_M1.faultMtrUse.all need to equal to "0" , if the values do not, check the current and voltage sensing circuit as described in Section 3.3.4.1.

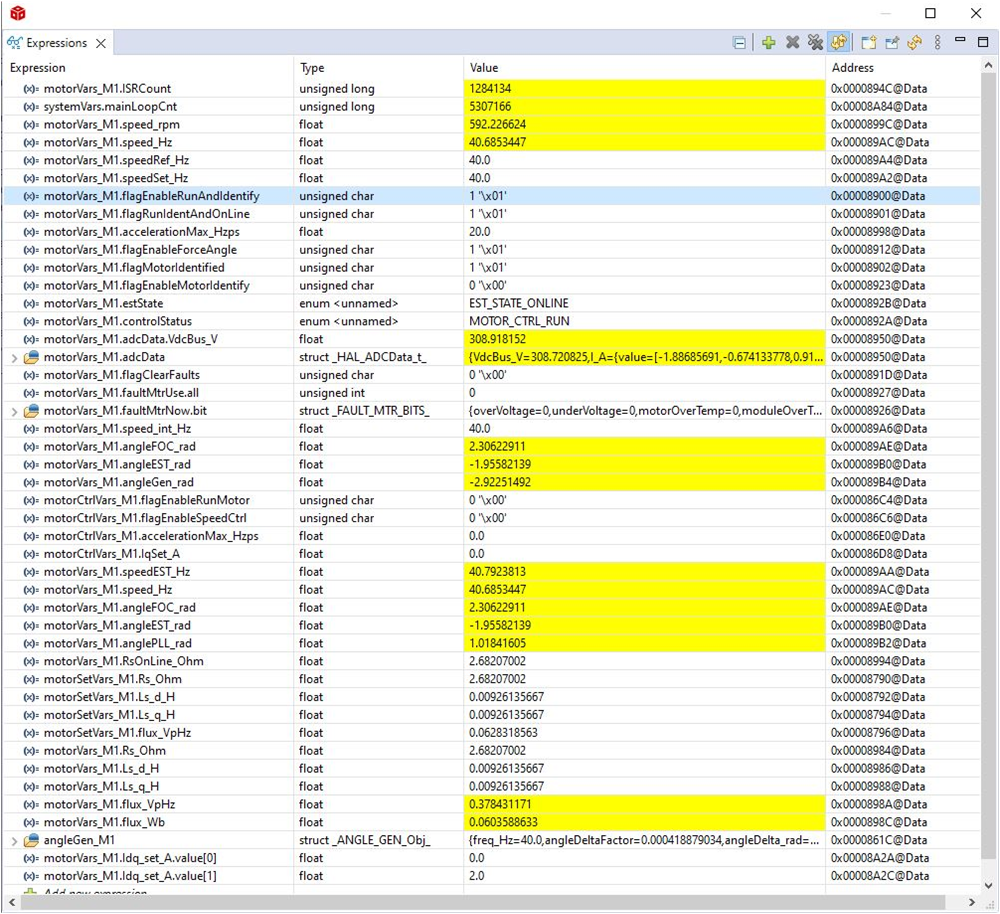

- To verify current closed-loop control for motor, set the variable motorVars_M1.flagEnableRunAndIdentify to "1" in the Expressions window as shown in Figure 3-33. The motor needs to run with a closed-loop control using the angle from the angle generator at a setting speed in the variable motorVars_M1.speedRef_Hz, check the value of motorVarsM1.speed_Hz in Expressions window, both variables value need to be very close.

- The motor current Iq can be set and changed with motorVars_M1.Idq_Set_A.value[1]

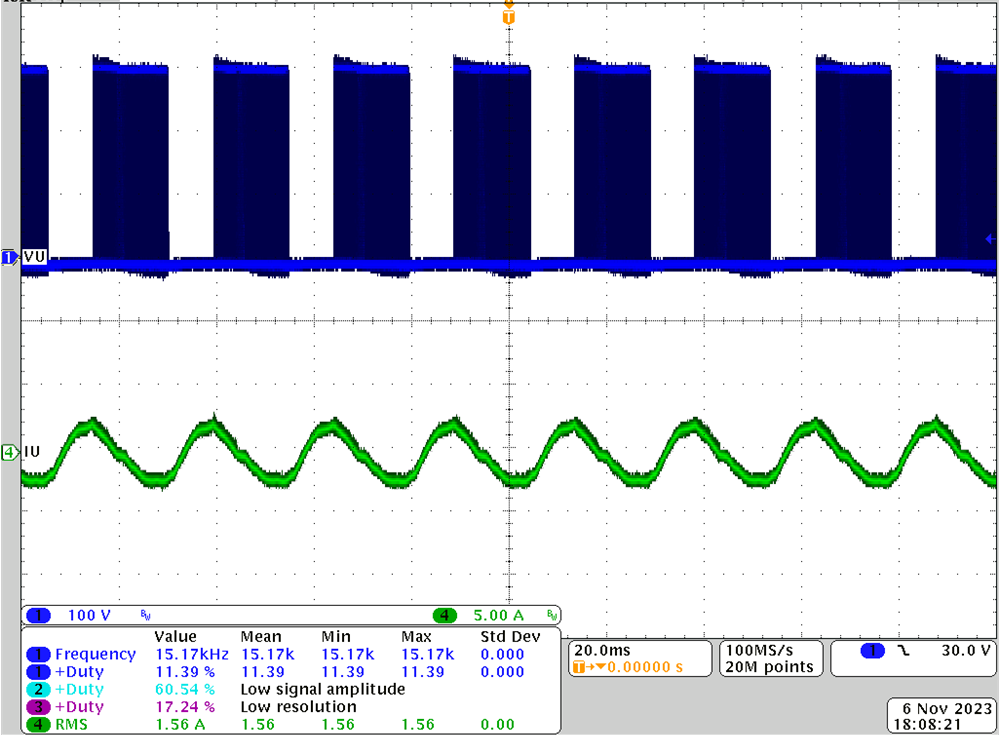

- Connect oscilloscope probes to IPM output to watch the motor phase voltage and current as shown in Figure 3-34. Change the Idq_set_A[0].value[1] in the Expressions window, the motor phase current needs to be increasing accordingly.

- If the motor cannot run with current-closed loop and appears to experience an overcurrent fault, check if the sign of adcData[0].current_sf and the value of userParams[0].current_sf are set correctly according to the hardware board.

- The controller can now be halted before setting

the motorVars_M1.flagEnableRunAndIdentify to "0", and the debug

connection terminated. Fully halting the controller by first clicking the

Halt button

on the toolbar or by clicking Target → Halt. Finally, reset the controller by clicking on

or clicking Run → Reset.

- Close CCS debug session by clicking on

Terminate Debug Session

or clicking Run → Terminate.

Figure 3-33 Build Level 3: Expressions Window at Run Time

Figure 3-33 Build Level 3: Expressions Window at Run Time Figure 3-34 Build Level 3: Motor Current Under 2-A

IQ Setting

Figure 3-34 Build Level 3: Motor Current Under 2-A

IQ Setting