SPRUJ87 june 2023

2.3 Interfaces

Major Components and Location

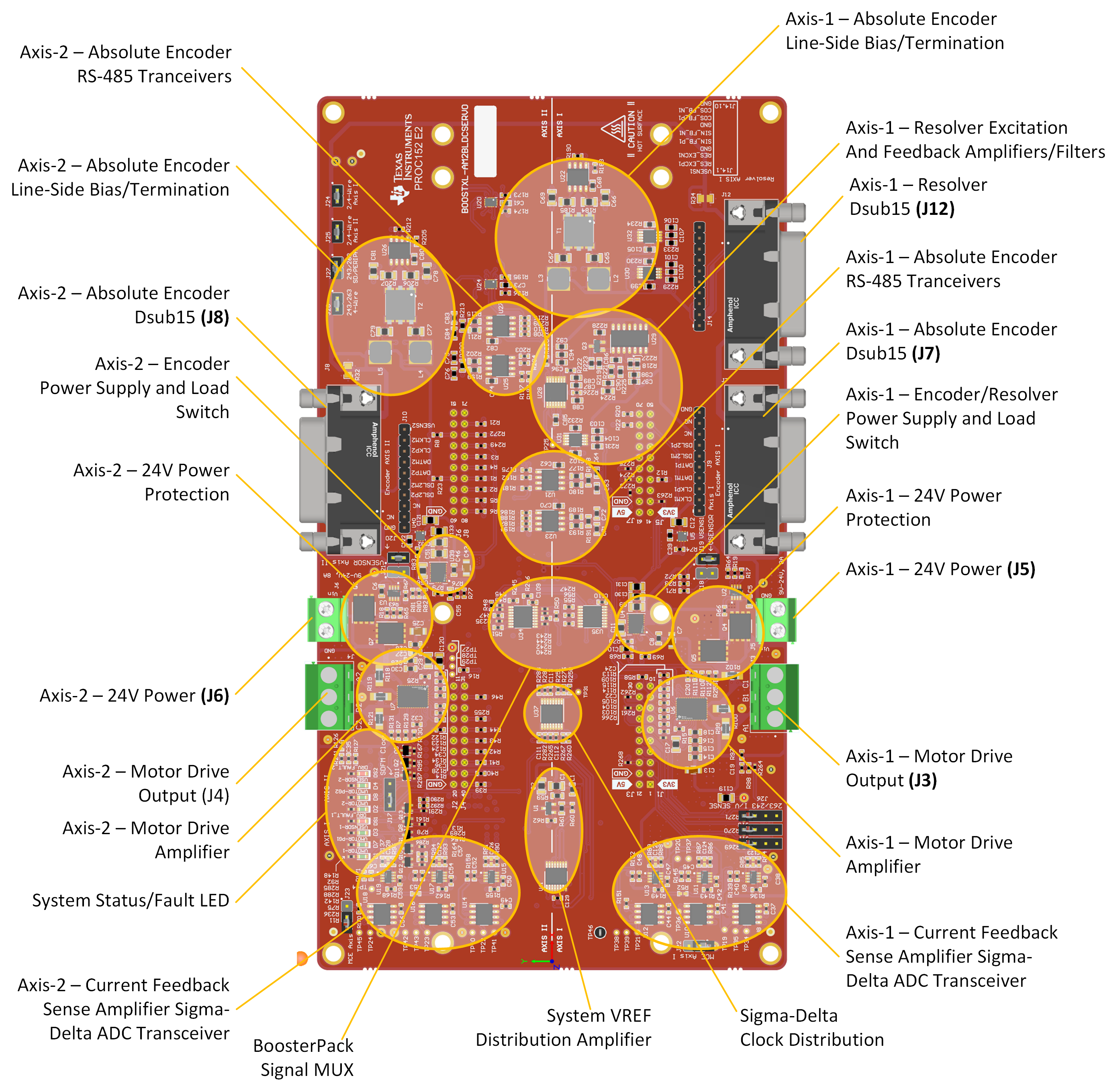

The below figures show the location of major connectors, components and circuit functions used on this design.

BP-AM2BLDCSERVO Top View, Major Component Areas and Connectors Highlighted

Figure 2-2 BP-AM2BLDCSERVO Top View,

Major Component Areas and Connectors Highlighted

Figure 2-2 BP-AM2BLDCSERVO Top View,

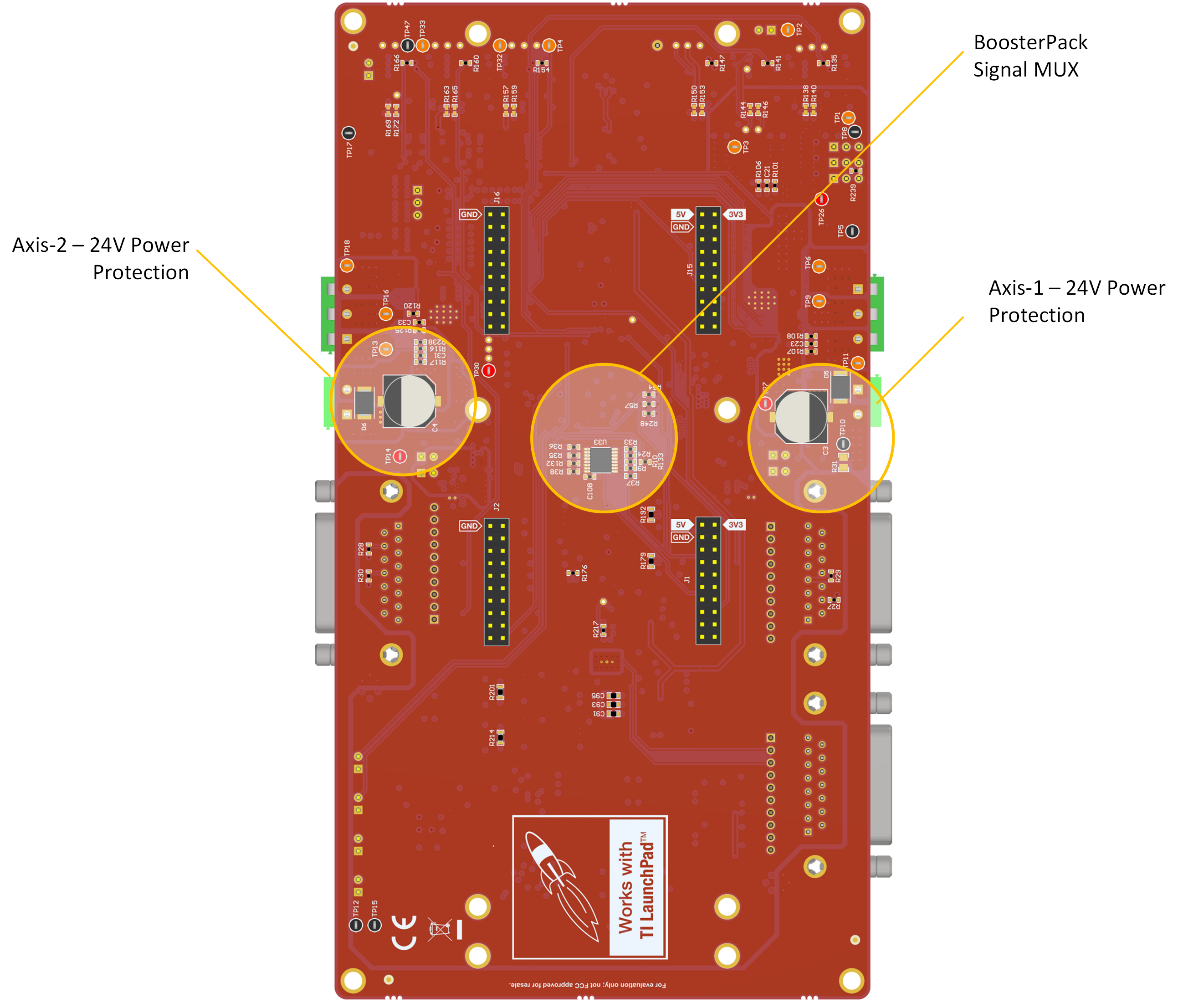

Major Component Areas and Connectors Highlighted Figure 2-3 BP-AM2BLDCSERVO Bottom View,

Major Component Areas and Connectors Highlighted

Figure 2-3 BP-AM2BLDCSERVO Bottom View,

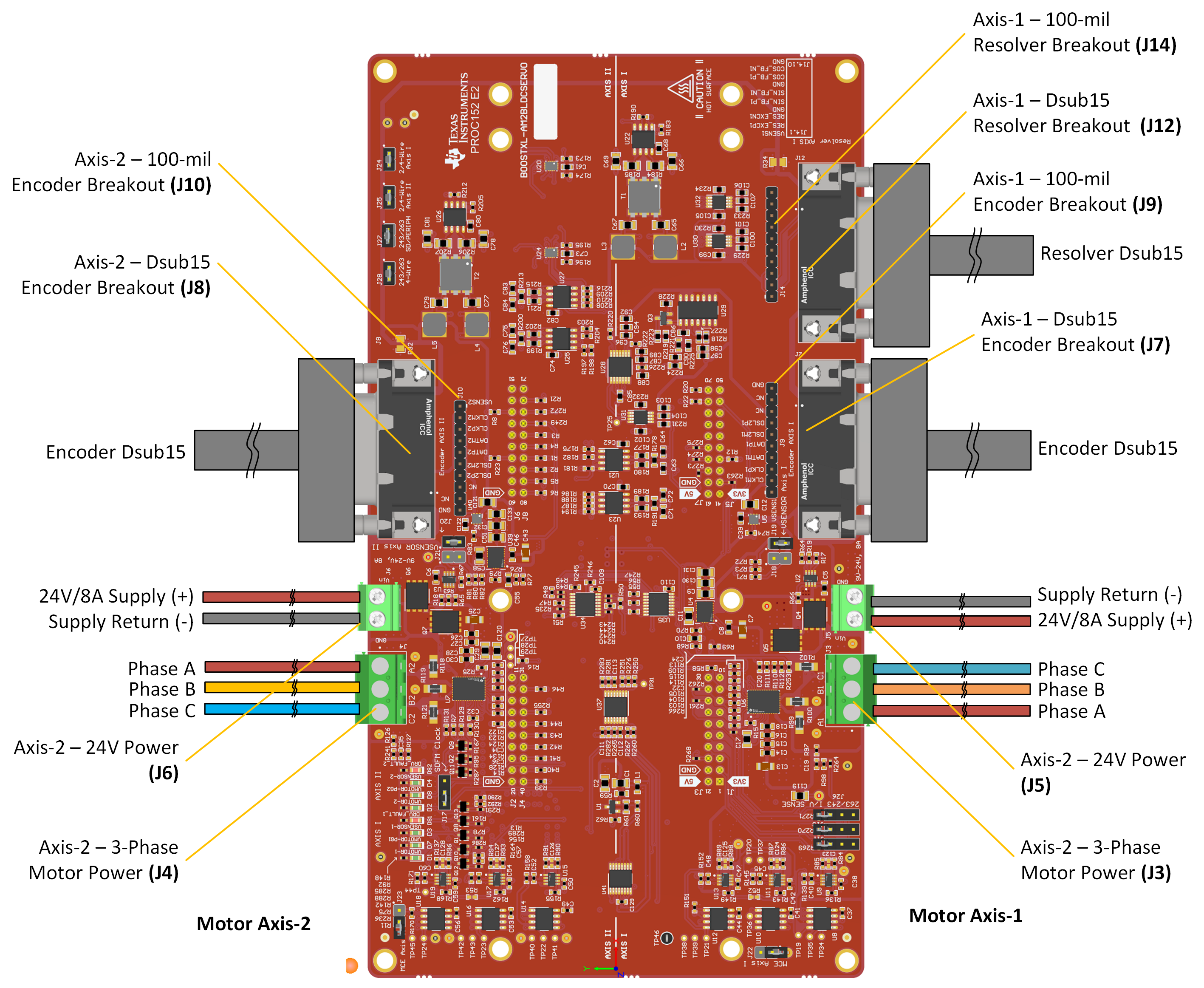

Major Component Areas and Connectors Highlighted Figure 2-4 BP-AM2BLDCSERVO Top View -

Connectors and Cables Overview

Figure 2-4 BP-AM2BLDCSERVO Top View -

Connectors and Cables Overview Typical Usage

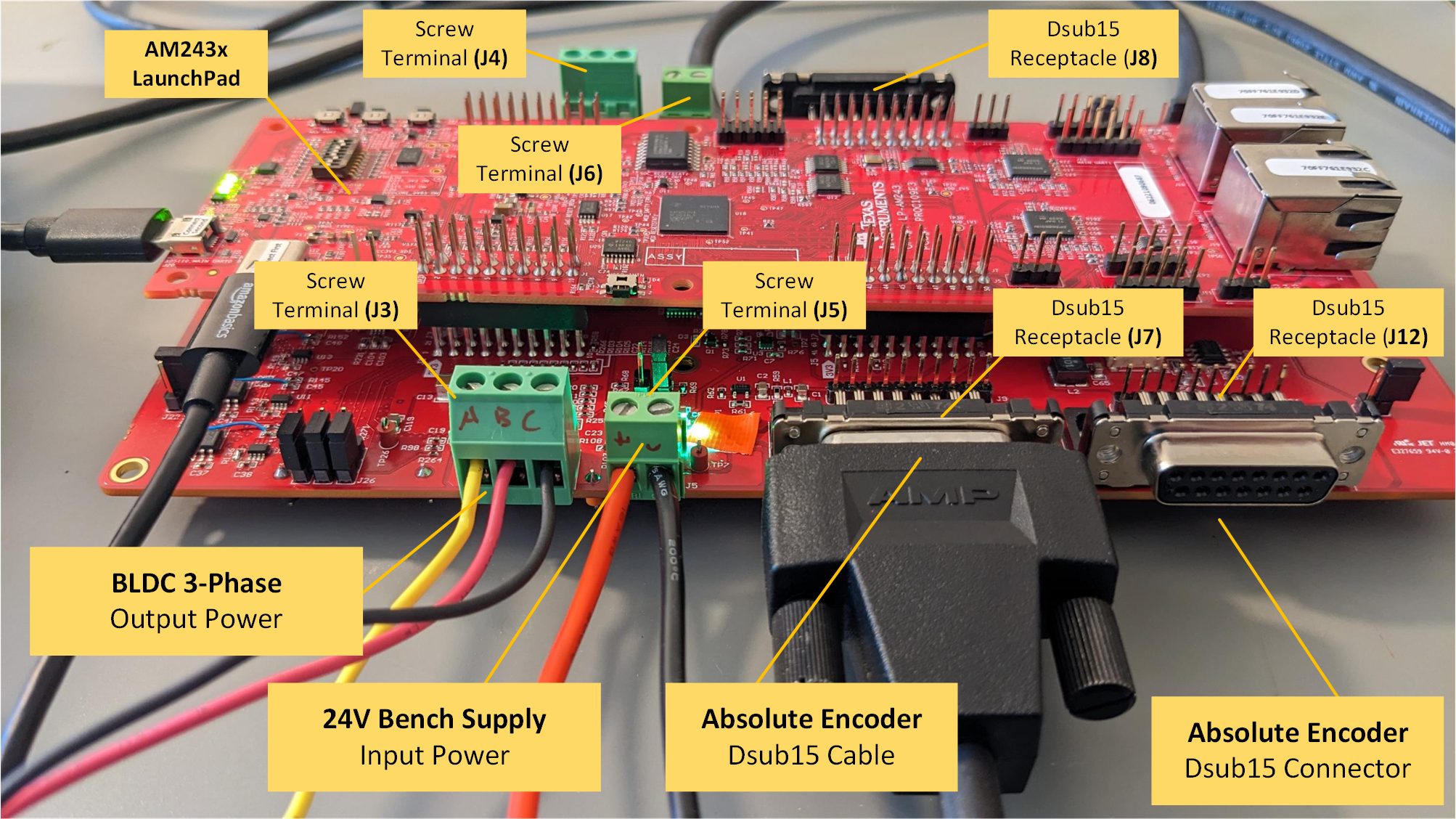

A typical setup for an axis-1, BLDC motor control scenario is shown below. The bench power, motor drive output and absolute encoder cables are shown attached. The attached LP-AM243 is shown with USB-C power and XDS110 debugger cable also attached.

Figure 2-5 BP-AM2BLDCSERVO and LP-AM243

LaunchPad - Axis-1 Power, Motor and Encoder cables attached

Figure 2-5 BP-AM2BLDCSERVO and LP-AM243

LaunchPad - Axis-1 Power, Motor and Encoder cables attached