SSZTAB1 march 2017 DRV8305-Q1 , ISOW7841 , LM5166 , LM5170-Q1 , LMG3410R070 , LMG5200 , TMS320F28035 , UCD3138A

Ten years ago, after years of constant urging from colleagues and customers alike, I realigned my calendar and headed to my first ever Applied Power Electronics Conference (APEC). I will be on hand this week in Tampa, which I believe marks the event’s 32nd year. In reviewing my last decade of participation, I have two notable observations – one involving a great deal of change and the other, not so much.

What hasn’t changed? The people! I love these people. This is a close, tight-knit, incredibly diverse and demonstrably intelligent community of innovators and engineers whom I trust, admire and respect. Their business cards may change, their hair may gray (or disappear altogether), but both the core and bulk of this community are steady and consistent. That is both fantastic (and concerning) to the future of power engineering, but I’ll leave that topic for another time.

Instead, let’s focus on what has been changing, and fairly dramatically. For the first 20 years of this who’s who in power electronics, the talks and papers, brightly lit hall exhibits and hush-hush back room discussions all focused on “chips and things.” Whether the topology of an integrated circuit (IC), the material used to make discrete products or the packaging of a particular type of module, fancy rectifier or high-powered thyristor, the content was primarily built to educate and display the science surrounding specific parts, components and products.

However, over the last 10 years, I’ve seen a dramatic rise and concentration on systems engineering and subsystem design. Companies help solve customer problems at the subsystem level by utilizing fantastic arrays of power ICs and technologies based on years of system design expertise. Now, all of those people whom I admire so much use their engineering knowledge to tackle the most difficult design challenges imaginable. They are continuously coming up with ideas aimed at improving applications using the most modern topologies and materials on the planet. They are now building comprehensive subsystem-level reference designs, and chasing efficiency and power-density goals that seemed unattainable at the turn of the century.

TI is not the only company taking a more refined approach to providing baked reference design approaches to industrial and automotive power systems. There is an APEC-wide movement afoot. I am, however, particularly excited to see the attendee reactions to some of TI’s latest reference design creations for industrial systems, which include:

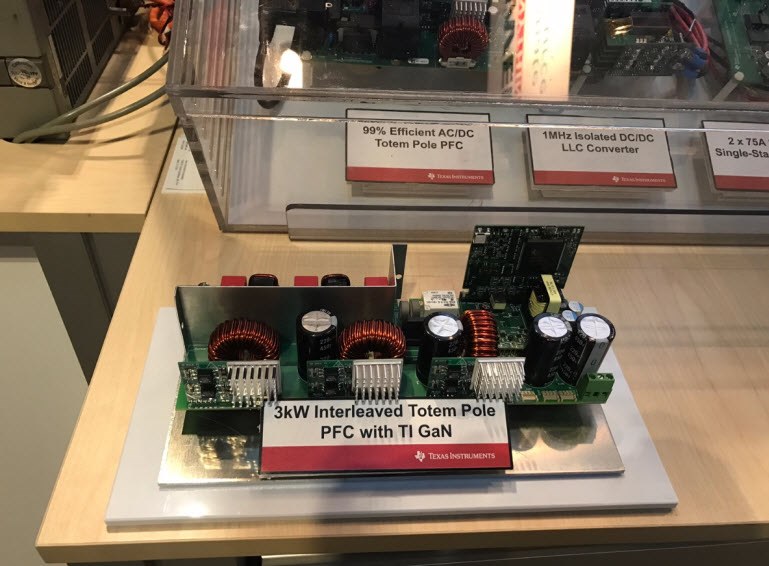

- GaN-based power system designs – from AC to processor: The industry’s first end-to-end high-frequency gallium nitride (GaN) power solution efficiently manages power from AC to point-of-load in space-constrained industrial, telecommunications and networking applications. Achieving 3x power density compared to existing solutions, TI will show off four separate reference designs based on its LMG5200 80V 10A integrated GaN FET and LMG3410 high-voltage GaN power-stage solutions. For more information, read the blog post, “The power to do even more with GaN”

- 480W bidirectional power converter for energy storage: The new 480W, 97% Efficiency Ultra-Compact (480W/in3) Bi-Directional DC/DC Reference Design is capable of delivering 480W/in3 with 97 percent efficiency in local energy storage (LES) and lithium battery backup power applications, specifically for server power-supply units. The 1-inch-by-1-inch-by-1-inch reference design is based on a two-phase interleaved half-bridge power stage controlled by TI’s UCD3138A digital power controller.

- PoE for industrial LED lighting in smart buildings: Extending its expertise in Power over Ethernet (PoE) applications, TI’s IEEE 802.3bt-compliant, PoE-enabled LED lighting ballast solution (51W Class 6) demonstrates ultra-low standby power consumption, connected lighting control over Ethernet and motion detection. This reference design helps engineers intelligently manage LED ballasts over Ethernet to light their industrial automation Internet of Things (IoT) designs for energy management, reactive room illumination, wayfinding and alert/alarm systems.

- Smart thermostat 24VAC power stage: The 24VAC Power Stage with Wide VIN Converter and Battery Gauge Reference Design for Smart Thermostat provides power and backup functionality to a Wi-Fi-enabled smart thermostat, which can be controlled with a phone.Adjusting the thermostat to a desired temperature illuminates the appropriate light, indicating cooling or heating. The power supply takes a 24VAC input; produces 5V and 3.3V output rails; features the new LM5166 synchronous buck converter with a maximum input voltage of 65V to help heating, ventilation and air-conditioning (HVAC) systems withstand transients; and has a low quiescent current of less than 10µA to maximize light-load efficiency. The design provides lithium-polymer battery charging and seamless switching to backup battery power during a 24VAC brownout.

- Non-military drone/robot battery management: The RC 2S1P battery management demonstration shows an interactive graphical user interface (GUI) that monitors a drone’s battery in real time – including state of charge, remaining time to empty and battery state of health. You can speed up or slow down the rotors and see the current and voltage profile of the battery. The Non-Military Drone, Robot or RC 2S1P Battery Management Solution Reference Design helps designers add flight time and extend battery life to quadcopters and other nonmilitary consumer and industrial drones.

- Start-stop effect on BLDC motor drives: This live demonstration shows the industry’s first automotive brushless DC (BLDC) gate driver operating at cold-crank voltages as low as 4.4V. The DRV8305-Q1 gate driver enables the pump to push fluid through the system in low-voltage conditions. The Automotive 12V 200W (20A) BLDC Motor Drive Reference Design was developed for 12V 200W (20A) BLDC motor drives in automotive applications.

- 12V to 48V bidirectional power-balancing system: The LM5170-Q1 reference design demonstration shows this new controller transferring current in either buck mode (48V to 12V) or boost mode (12V to 48V) operation. The controller operates smoothly through a dynamic change in current direction without any overshoot. This enables each phase to remain enabled while the direction input changes, simplifying any sequencing of input signals and allowing for smooth transitions between buck or boost mode.

- Integrated isolated data- and power-enabling industrial system: This demonstration compares the thermal performance of TI’s new ISOW7841 reinforced isolator (with integrated power) to a similar device available in the market today. The ISOW7841 offers 80% higher efficiency over existing integrated devices. With low power consumption, the isolator reduces device operating temperatures by up to 40°C, enabling higher power delivery, higher channel count and longer system life than other integrated solutions.

- High-efficiency USB-Type C™ charging: Several USB Type-C charging reference designs include key features such as high switching frequency, low electromagnetic interference (EMI), low quiescent current and wide input voltage. The USB Type-C reference designs include:

-

- USB Type-C PD DFP 5/12/20V3A Output with 2-3 Cell Battery Input Power Bank Reference Design.

- CISPR 25 Class 5 USB Type-C Port Reference Design with USB 3.0 Data Support.

- USB Type-C DFP 5V 3A Car Charger Reference Design.

- 36W USB Dual Port USB Type-C PD Reference Design with Port Power Management DC/DC Charger.

- 60kW fast DC EV charging station: The 60kW charging station from Xuji is one of 4 million electric vehicle (EV) charging stations planned for deployment throughout China by 2020. This charging station is equipped with eight 7.5kW power modules using two C2000™ Piccolo™ F2803x devices per module. It also features TI processors for human-machine interface (HMI), high-voltage sensing components and high-voltage gate drivers for improved efficiency and accurate sensing. The charging station is based on TI’s new Vienna Rectifier-Based Three Phase Power Factor Correction Reference Design Using C2000 MCU, which minimizes energy loss by monitoring power conversion to and from the battery and improves power-conversion efficiencies inside the charging station.

Figure 1 3kW Interleaved Totem Pole

PFC, GaN-based Reference Design Featured at APEC 2017

Figure 1 3kW Interleaved Totem Pole

PFC, GaN-based Reference Design Featured at APEC 2017 Figure 2 End-to-end GaN Solution - from

AC to Point-of-load

Figure 2 End-to-end GaN Solution - from

AC to Point-of-loadAdditional Resources

- 99% Efficient 1kW GaN-based CCM Totem-pole Power Factor Correction (PFC) Converter Reference Design

- High Efficiency and High Power Density 1kW Resonant Converter Reference Design with TI HV GaN FET

- View the new white paper, “Evolving high-voltage power delivery through the power process chain.”

- More information and reference designs: www.ti.com/tidesigns.