SWRU548C February 2019 – September 2021 CC3235MODAS , CC3235MODASF , CC3235MODS , CC3235MODSF

- 1Introduction

-

2Hardware

- 2.1 Block Diagram

- 2.2

Hardware Features

- 2.2.1 Key Benefits

- 2.2.2 XDS110-Based Onboard Debug Probe

- 2.2.3 Debug Probe Connection: Isolation Jumper Block

- 2.2.4 Application (or "Backchannel") UART

- 2.2.5 JTAG Headers

- 2.2.6 Using the XDS110 Debug Probe with a Different Target

- 2.2.7 Power Connections

- 2.2.8 Reset Pullup Jumper

- 2.2.9 Clocking

- 2.2.10 I2C Connection

- 2.2.11 Sense on Power (SOP)

- 2.2.12 Push-Buttons and LED Indicators

- 2.3 Electrical Characteristics

- 2.4 Antenna Characteristics

- 2.5 BoosterPack Plug-in Module Pinout

- 3Layout Guidelines

- 4Operational Setup and Testing

- 5Development Environment Requirements

- 6Additional Resources

- 7Assembly Drawing and Schematics

3.3 RF Layout Recommendations

The RF section of this wireless module gets top priority in terms of layout. It is very important for the RF section to be laid out correctly to ensure optimum performance from the module. A poor layout can cause low-output power, EVM degradation, sensitivity degradation, and mask violations.

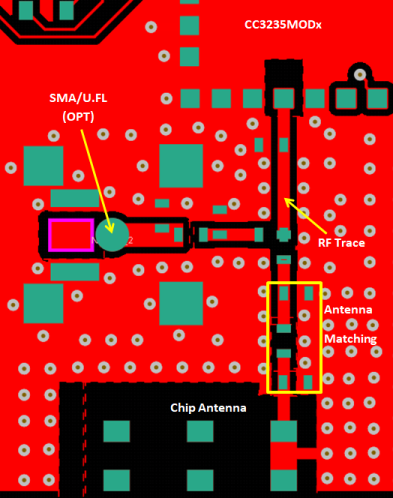

Figure 3-5 shows the RF placement and routing of the CC3235MODSF module.

Figure 3-5 RF Section Layout

Figure 3-5 RF Section LayoutUse the following RF layout recommendations for the CC3235MODx module:

- RF traces must have 50-Ω impedance.

- RF trace bends must be made with gradual curves, and 90 degree bends must be avoided.

- RF traces must not have sharp corners.

- There must be no traces or ground under the antenna section.

- RF traces must have via stitching on the ground plane beside the RF trace on both sides.

- RF traces must be as short as possible. The antenna, RF traces, and the module must be on the edge of the PCB product in consideration of the product enclosure material and proximity.

For optimal RF performance, ensure the copper cut out on the top layer under the RF-BG pin (pin 31) is as shown in Figure 3-6.

Figure 3-6 Top Layer Copper Pullback on RF Pads

Figure 3-6 Top Layer Copper Pullback on RF Pads