SLYY193C january 2023 – april 2023 LMQ61460-Q1 , TPS54319 , TPS62088 , TPS82671 , UCC12040 , UCC12050

- At a glance

- Authors

- 3

- What is power density?

- What limits power density?

- What limits power density: switching losses

- Key limiting factor No. 1: charge-related losses

- Key limiting factor No. 2: reverse-recovery losses

- Key limiting factor No. 3: turn-on and turn-off losses

- What limits power density: thermal performance

- How to break through power density barriers

- Switching loss innovations

- Package thermal innovations

- Advanced circuit design innovations

- Integration innovations

- Conclusion

- Additional resources

What is power density?

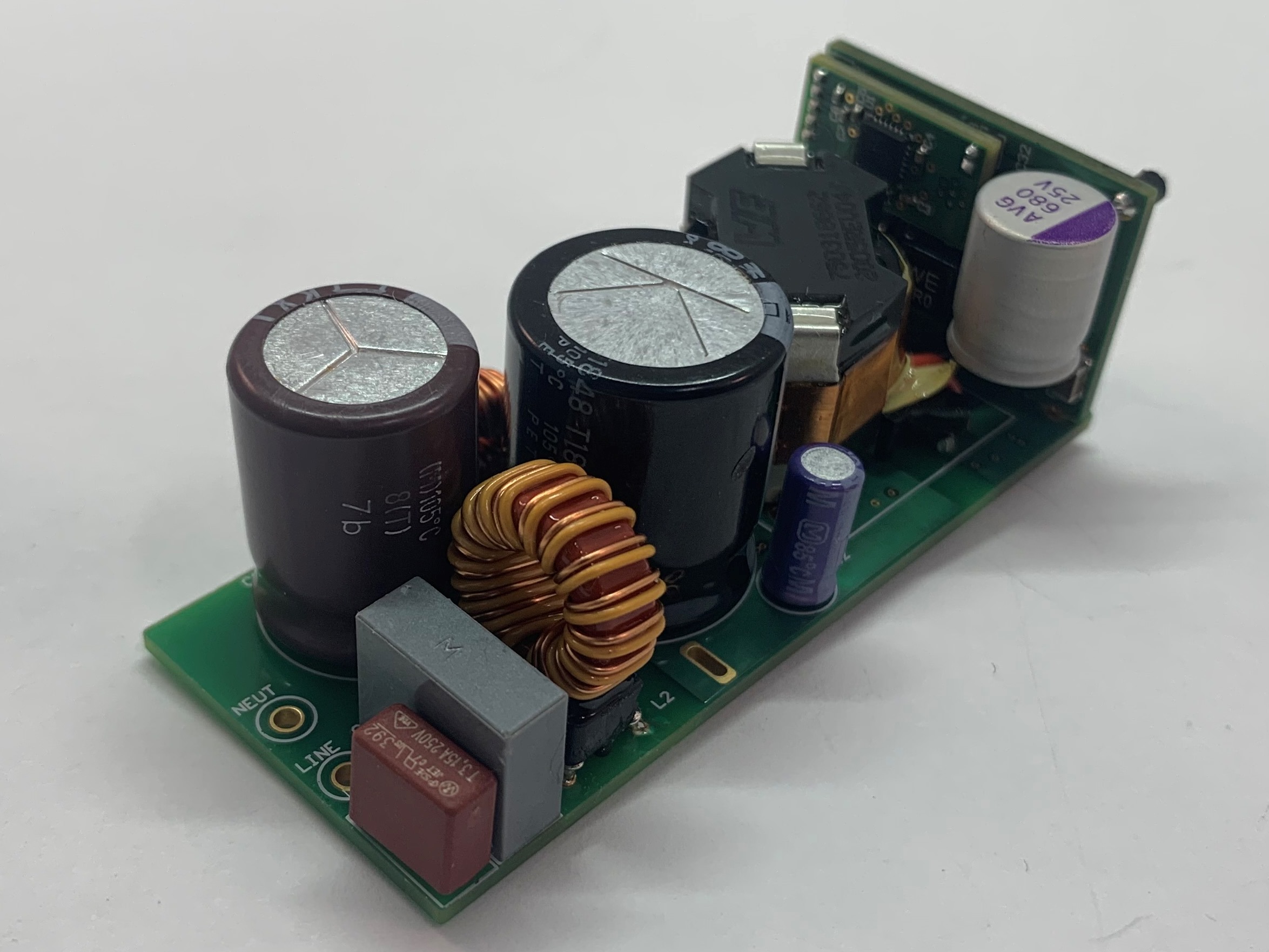

Power density is a measure of how much power can be processed in a given space, quantifiable as the amount of power processed per unit of volume in units of watts per cubic meter (W/m3) or watts per cubic inch (W/in3). These values are based on the converter power rating and the box volume (length × width × height) of the power solution with all components included, as shown in Figure 2. It is possible to scale the units to the appropriate power level or size. For example, kilowatts per liter is a common figure of merit (FoM) for onboard battery chargers in electric vehicles because these power converters provide kilowatt levels of power (between 3 kW and 22 kW).

Figure 2 A 65-W active clamp flyback converter measuring 65 mm by 28 mm by 25 mm.

Figure 2 A 65-W active clamp flyback converter measuring 65 mm by 28 mm by 25 mm.Current density is a metric related to power density and is quite useful, quantifiable as current per unit of volume in units of amperes per cubic inch or amperes per cubic millimeter. The converter current rating (usually either input current or output current) is used in the calculation of current density.

Current density is often a more appropriate FoM to apply in applications like point-of-load voltage regulators. The size of these designs scales with output current, and the output voltage levels are typically low, around 1 V. It is possible to artificially inflate power density numbers by assuming an unrealistically high output voltage; thus, current density is a more effectual metric because it removes the output voltage from consideration.

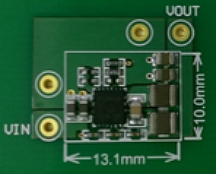

Sometimes volumetric density is not important. The power electronics may not be height-constrained, since other portions of the design are considerably taller. Instead, circuit board area could be the limiting factor. Improving power density in these situations could entail finding ways to stack or 3D-integrate components to reduce the power solution footprint. You would then modify the metrics used to compare solutions to watts per square millimeter or amperes per square inch, which highlights the key design goal (as shown in Figure 3).

Figure 3 A 10-A point-of-load converter measuring 13.1 mm by 10 mm in area, resulting in 76 mA/mm2 of current density.

Figure 3 A 10-A point-of-load converter measuring 13.1 mm by 10 mm in area, resulting in 76 mA/mm2 of current density.You can view power density in a few different ways depending on the application, but the goal remains the same: Reducing solution size leads to improvements in power density. The question now is how to get those gains in power density.