DLPS096B November 2017 – May 2022 DLPC120-Q1

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Conditions

- 6.4 Thermal Information

- 6.5 Electrical Characteristics

- 6.6 Electrical Characteristics for I/O

- 6.7 Power Supply and Reset Timing Requirements

- 6.8 Reference Clock PLL Timing Requirements

- 6.9 Parallel Interface General Timing Requirements

- 6.10 Parallel Interface Frame Timing Requirements

- 6.11 Flash Memory Interface Timing Requirements

- 6.12 DMD Interface Timing Requirements

- 6.13 JTAG Interface Timing Requirements

- 6.14 I2C Interface Timing Requirements

- 7 Parameter Measurement Information

- 8 Detailed Description

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- ZXS|216

Thermal pad, mechanical data (Package|Pins)

Orderable Information

5 Pin Configuration and Functions

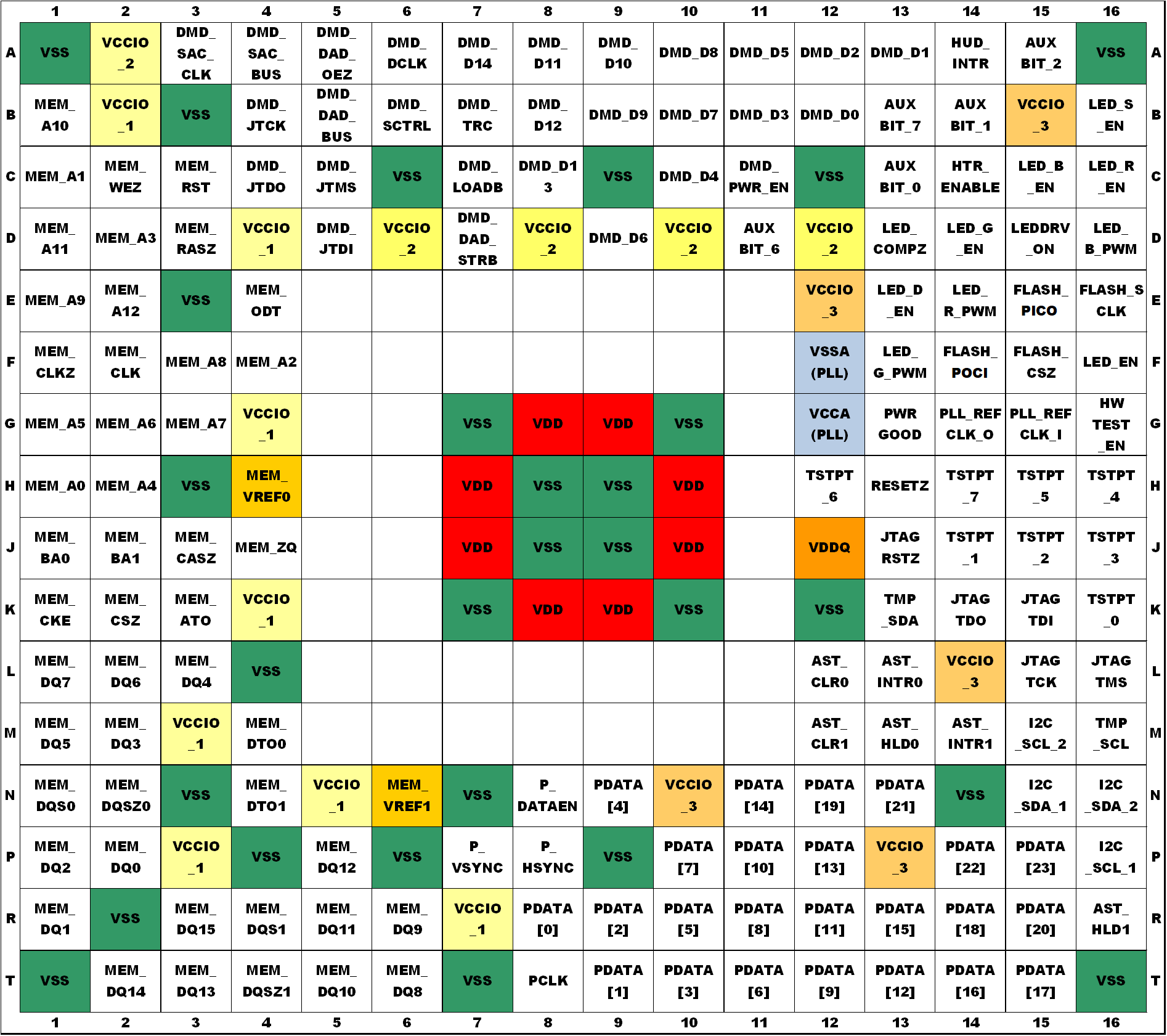

Figure 5-1 ZXS Package216-Pin BGATop View

Figure 5-1 ZXS Package216-Pin BGATop ViewTable 5-1 DLPC120-Q1 Device Initialization and Programming Pin Descriptions

| PIN | I/O | I/O | CLOCK | ||

|---|---|---|---|---|---|

| NAME | NO. | POWER | TYPE | SYSTEM | DESCRIPTION |

| RESETZ | H13 | 3.30 V | I2 | Async | Functional Reset (Active Low). Resets internal logic and causes PLL startup and PLL locking. Assertion is required after power supplies are within limits. See Section 6.7 for timing requirements. |

| PWRGOOD | G13 | I2 | Async | System Power Good indicator. Should be held low until all DLPC120-Q1 power has been within operating limits. See Section 6.7 for timing requirements. Must be set high to enable normal operation. When set low, the DLPC120-Q1 begins the parking routine for the DMD. Together with pin E14 (LED_R_PWM / PWRGOOD_CNTRL), this signal is critical for DLP30xx-Q1 parking as part of the Pre-Conditioning Sequence and subsequent un-parking. See DLPC120-Q1 Programmer's Guide for implementation details. | |

| PLL_REFCLK_I | G15 | I2 | N/A | Reference Clock Input (16 MHz). Can be driven by crystal across this pin and PLL_REFCLK_O or by external oscillator. See Section 6.7 for timing requirements. | |

| PLL_REFCLK_O | G14 | O6 | N/A | Crystal output. Used with PLL_REFCLK_I. | |

| HUD_INTR | A14 | O6 | N/A | Interrupt signal. This active high signal indicates one of the interrupt sources in the controller has been triggered. | |

| IIC_SCL_1 | P16 | B8 | N/A | I2C Clock for Device configuration and control. Requires external pull-up. Port 1 peripheral command/control interface. | |

| IIC_SDA_1 | N15 | B8 | N/A | I2C Data for Device configuration and control. Requires external pull-up. Port 1 peripheral command/control interface. | |

| IIC_SCL_2 | M15 | B8 | N/A | I2C Clock Debug Port. Requires external pull-up. Port 2 peripheral command/control interface. | |

| IIC_SDA_2 | N16 | B8 | N/A | I2C Data Debug Port. Requires external pull-up. Port 2 peripheral command/control interface. | |

| FLASH_POCI | F14 | I2 | FLASH_SCLK | Serial Data input from the external SPI Flash device. This provides device logical programming data as well as functional configuration parameter data. | |

| FLASH_CSZ | F15 | O6 | FLASH_SCLK | Chip Select output for the external SPI Flash device. Active low. | |

| FLASH_SCLK | E16 | O6 | N/A | Clock for the external SPI Flash device. | |

| FLASH_PICO | E15 | O6 | FLASH_SCLK | Serial Data output to the external SPI Flash device. This pin sends address and control information as well as data when programming. | |