SNLS568D March 2017 – May 2020 LMH1228

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 4-Level Input Pins and Thresholds

- 7.3.2 OUT0_SEL and SDI_OUT2_SEL Control

- 7.3.3 Input Signal Detect

- 7.3.4 Continuous Time Linear Equalizer (CTLE)

- 7.3.5 Clock and Data (CDR) Recovery

- 7.3.6 Internal Eye Opening Monitor (EOM)

- 7.3.7 Output Function Control

- 7.3.8 Output Driver Control

- 7.3.9 Status Indicators and Interrupts

- 7.4 Device Functional Modes

- 7.5 Register Maps

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- RTV|32

Thermal pad, mechanical data (Package|Pins)

- RTV|32

Orderable Information

8.2.1.3 Application Curves

The LMH1228 performance on SDI_OUT1+ and SDI_OUT2+ was measured with the test setups shown in Figure 22 and Figure 23.

Figure 22. Test Setup for LMH1228 to SDI_OUT1+

Figure 22. Test Setup for LMH1228 to SDI_OUT1+  Figure 23. Test Setup for LMH1228 to SDI_OUT2+

Figure 23. Test Setup for LMH1228 to SDI_OUT2+ The eye diagrams in this subsection show how the LMH1228 improves overall signal integrity in the data path for 100-Ω differential FR4 PCB trace at IN0±.

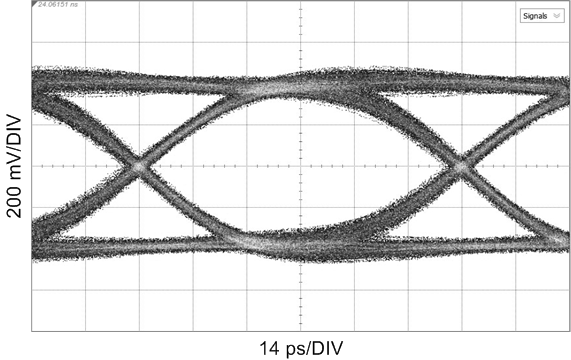

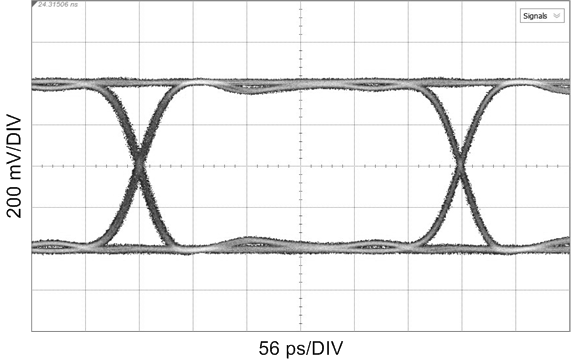

Measured at SDI_OUT1+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 24. 11.88 Gbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

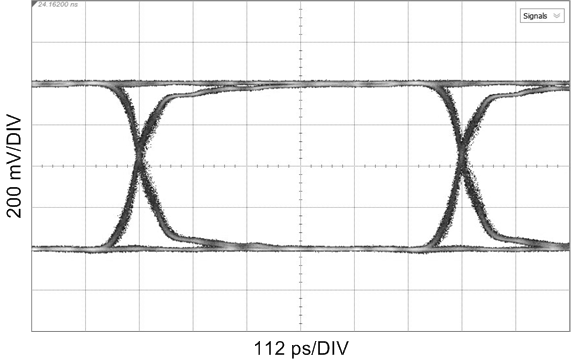

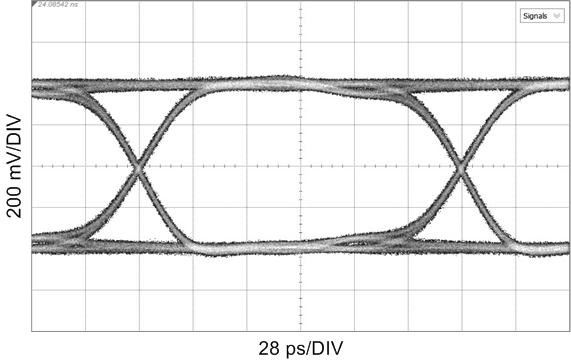

Measured at SDI_OUT1+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 26. 5.94 Gbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

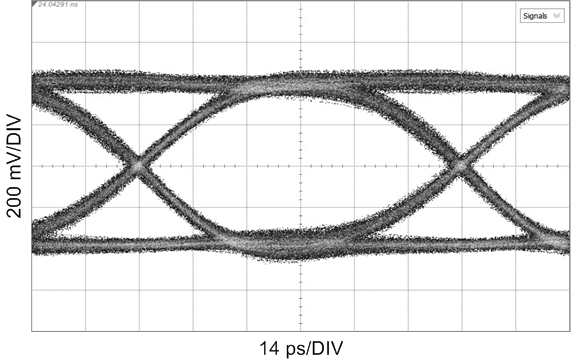

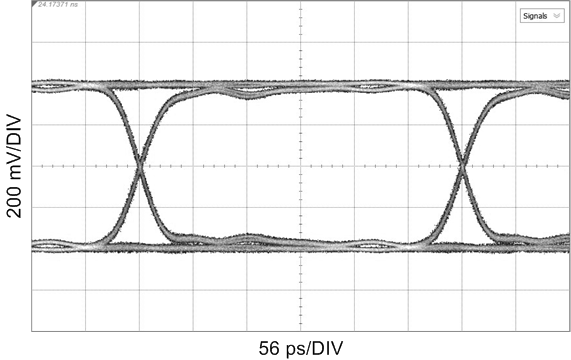

Measured at SDI_OUT1+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 28. 2.97 Gbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

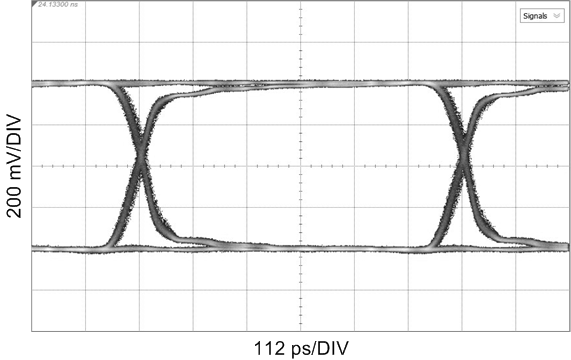

Measured at SDI_OUT1+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 30. 1.485 Gbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

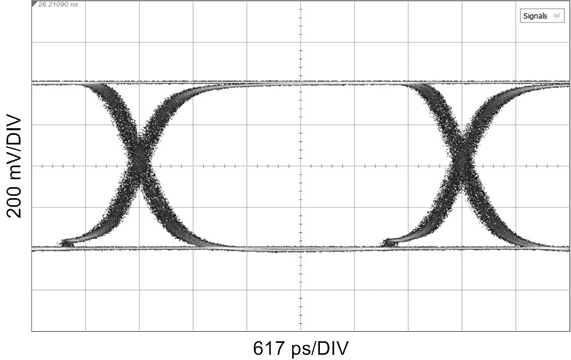

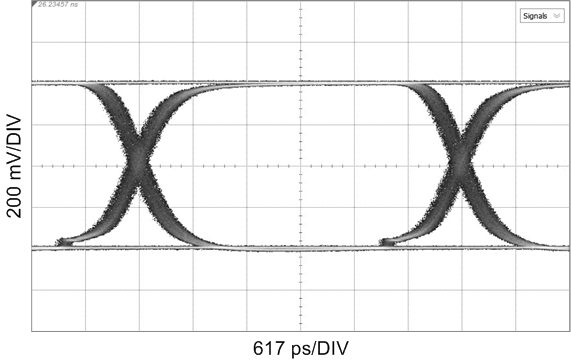

Measured at SDI_OUT1+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 32. 270 Mbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

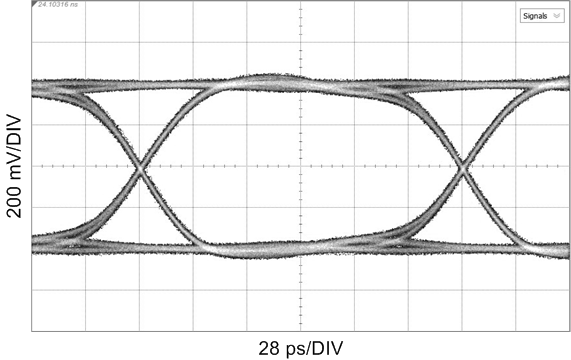

Measured at SDI_OUT2+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 25. 11.88 Gbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Measured at SDI_OUT2+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 27. 5.94 Gbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Measured at SDI_OUT2+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 29. 2.97 Gbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Measured at SDI_OUT2+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 31. 1.485 Gbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Measured at SDI_OUT2+

HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F

Figure 33. 270 Mbps, TL = 20" FR4, Reclocked HOST_EQ0 = F, SDI_OUT2_SEL = L, OUT_CTRL = F