SNVSAN3F August 2017 – November 2020 LMR33630

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Detailed Description

-

9 Application and Implementation

- 9.1 Application Information

- 9.2

Typical Application

- 9.2.1 Design Requirements

- 9.2.2

Detailed Design Procedure

- 9.2.2.1 Custom Design With WEBENCH® Tools

- 9.2.2.2 Choosing the Switching Frequency

- 9.2.2.3 Setting the Output Voltage

- 9.2.2.4 Inductor Selection

- 9.2.2.5 Output Capacitor Selection

- 9.2.2.6 Input Capacitor Selection

- 9.2.2.7 CBOOT

- 9.2.2.8 VCC

- 9.2.2.9 CFF Selection

- 9.2.2.10 External UVLO

- 9.2.2.11 Maximum Ambient Temperature

- 9.2.3 Application Curves

- 9.3 What to Do and What Not to Do

- Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- RNX|12

- DDA|8

Thermal pad, mechanical data (Package|Pins)

Orderable Information

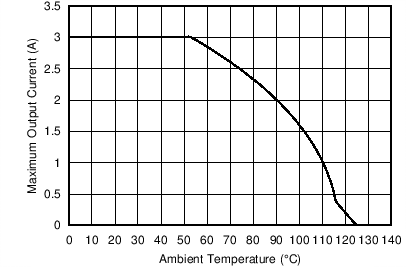

9.2.2.11 Maximum Ambient Temperature

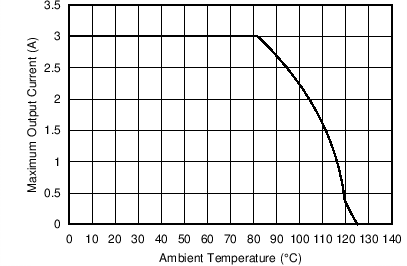

As with any power conversion device, the LMR33630 dissipates internal power while operating. The effect of this power dissipation is to raise the internal temperature of the converter above ambient. The internal die temperature (TJ) is a function of the ambient temperature, the power loss and the effective thermal resistance, RθJA of the device and PCB combination. The maximum internal die temperature for the LMR33630 must be limited to 125°C. This establishes a limit on the maximum device power dissipation and therefore the load current. Equation 11 shows the relationships between the important parameters. It is easy to see that larger ambient temperatures (TA) and larger values of RθJA reduce the maximum available output current. The converter efficiency can be estimated by using the curves provided in this data sheet. If the desired operating conditions cannot be found in one of the curves, then interpolation can be used to estimate the efficiency. Alternatively, the EVM can be adjusted to match the desired application requirements and the efficiency can be measured directly. The correct value of RθJA is more difficult to estimate. As stated in the Semiconductor and IC Package Thermal Metrics Application Report, the value of RθJA given in Section 7.4 is not valid for design purposes and must not be used to estimate the thermal performance of the application. The values reported in that table were measured under a specific set of conditions that are rarely obtained in an actual application.

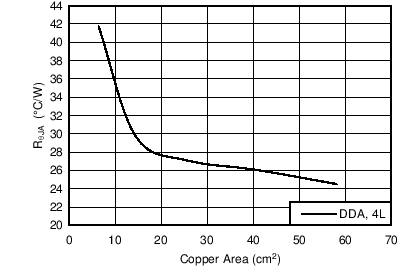

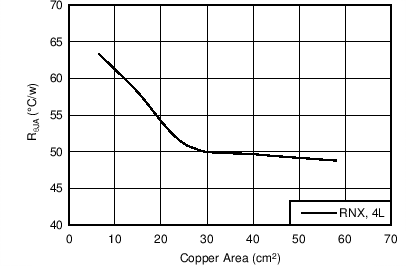

where

- η = efficiency

The effective RθJA is a critical parameter and depends on many factors such as power dissipation, air temperature/flow, PCB area, copper heat-sink area, number of thermal vias under the package, and adjacent component placement; to mention just a few. The HSOIC (DDA) package utilizes a die attach paddle, or thermal pad (PAD) to provide a place to solder down to the PCB heat-sinking copper. This provides a good heat conduction path from the regulator junction to the heat sink and must be properly soldered to the PCB heat sink copper. Due to the ultra-miniature size of the VQFN (RNX) package, a DAP is not available. This means that this package exhibits a somewhat large value RθJA.Typical examples of RθJA vs copper board area can be found in Figure 9-3 and Figure 9-4. The copper area given in the graph is for each layer; the top and bottom layers are 2 oz. copper each, while the inner layers are 1 oz. Typical curves of maximum output current vs ambient temperature are shown in Figure 9-5 and Figure 9-6. This data was taken with a device/PCB combination giving an RθJA as noted in the graph. It must be remembered that the data given in these graphs are for illustration purposes only, and the actual performance in any given application depends on all of the previously mentioned factors.

Figure 9-3 Typical RθJA versus Copper Area for a Four-Layer Board and the HSOIC (DDA) Package

Figure 9-3 Typical RθJA versus Copper Area for a Four-Layer Board and the HSOIC (DDA) Package

| VIN = 12 V | VOUT = 5 V | |

| ƒSW = 400 kHz | RθJA = 30°C/W |

| VIN = 12 V | VOUT = 5 V | |

| ƒSW = 400 kHz | RθJA = 50°C/W |

Use the following resources as a guide to optimal thermal PCB design and estimating RθJA for a given application environment: