DLPA027B January 2024 – April 2024 DLP500YX , DLP5500 , DLP6500FLQ , DLP6500FYE , DLP650LNIR , DLP670S , DLP7000 , DLP7000UV , DLP9000 , DLP9000X , DLP9000XUV , DLP9500 , DLP9500UV

3 Sample Calculations

Below are detailed sample calculations that show how mirror surface temperature is calculated using the three temperature rises:

- Mirror Surface to Bulk Mirror Delta

- Bulk Mirror to Silicon Delta

- Silicon to Ceramic Delta

In the first example calculation, toff is greater than , therefore the bulk mirror fully cools after each pulse and only one pulse needs to be analyzed.

Example 1

A pulsed laser illuminates a DLP650LNIR DMD with 1064 nm wavelength light and fills the active array with no overfill.

Pulse duration (tpulse) = 1

toff = 999 (pulsed repetition rate of the optical source is 1 kHz)

Peak incident power during the pulse is 25 kW/cm2

Calculation of the temperature rise of the mirror surface above the DMD ceramic temperature:

- Mirror Surface to Bulk Mirror

Delta: ΔTMIRROR_SURFACE-TO-BULK_MIRROR

= temperature at time = t

= initial mirror temperature

q = absorbed heat flux on mirror surface [W/m2]

α = Mirror thermal diffusivity = 6.4667 x 10-5 m2/s

k = Mirror thermal conductivity = 160 W/m-ºC

q = 25 kW/cm2 × (1 – 0.94) = 1.50 kW/cm2

tpulse = 1

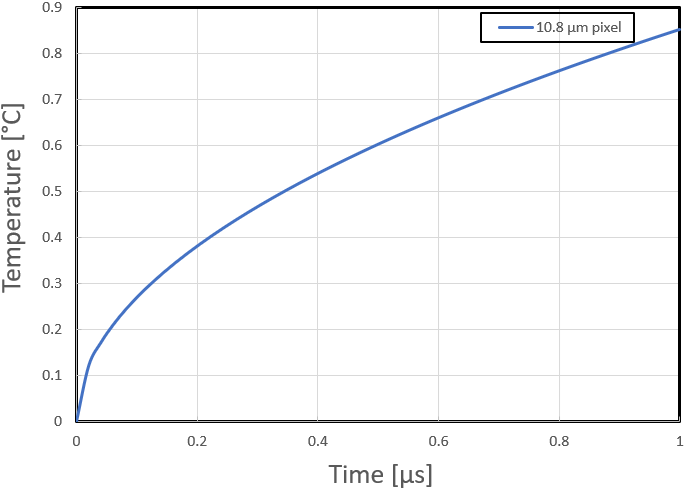

T(1 ) = 2 × 1.50 kW/cm2 × {[(6.4667e-5 m2/s × 1.0e-6 s)/π] /160 W/m-ºC} + 0 = 0.85 ºC

Figure 3-1 DMD Mirror Surface

Temperature Rise at 25 kW/cm2

Figure 3-1 DMD Mirror Surface

Temperature Rise at 25 kW/cm2 - Bulk Mirror to Silicon Delta:

ΔTBULK_MIRROR-TO-SILICON

= 25 kW/cm2 × (10.8 μm)2 = 0.02916 W

= 0.931 (on-state)

at 1064 nm = 0.94

= 0.02916 W × [0.931 × (1 – 0.94)] = 1.629 mW

= 3.39 x 105 ºC/W

= 0 + 1.629 mW × (3.39 x 105 ºC/W) = 552.23 ºC

= 32.27

toff = 999

tpulse = 1

= 5 × 32.27 = 161.35

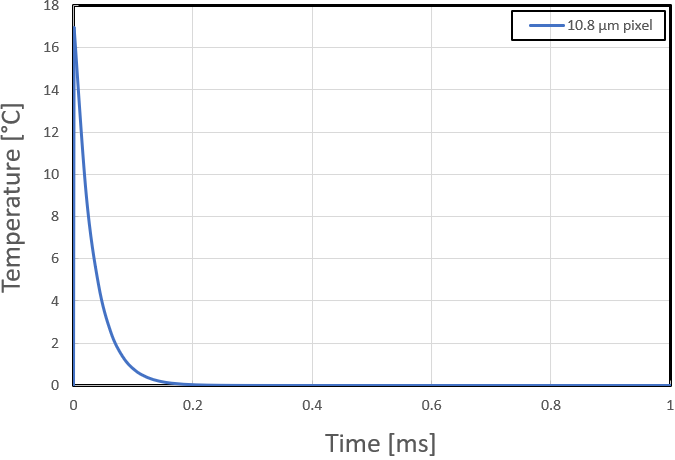

Since toff = 999 (> ) the bulk mirror fully cools to the initial temperature Ti and analyzing a single pulse cycle is sufficient.

T(1 ) = 552.23 ºC + (0 – 552.23 ºC)e-(1 μs/32.27 μs) = 16.85 ºC

Figure 3-2 DMD Bulk Mirror

Temperature Rise 25 kW/cm2

Figure 3-2 DMD Bulk Mirror

Temperature Rise 25 kW/cm2 - Silicon to Ceramic Delta: ΔTSILICON-TO-CERAMIC

From the DLP650LNIR data sheet:

= 0.5 ºC/W

= 1.8 W

= 0.726 (off-state)

at 1064 nm = 0.94

at 1064 nm = 0.007 (per pass)

= 0

= (1 - 0) × {[0.726 × (1-0.94)] + [1-0.726]} + (2 × 0.007) + 0

= 0.33 (off-state)

= total incident average optical power to DMD

Active array area = (1280 × 10.8 μm) × (800 × 10.8 μm) = 1.1944 cm2

tpulse = 1 , toff = 999

Therefore pulse duty cycle = 1 / ( 1 + 999 ) x 100% = 0.1%

Average optical power density = (25 kW/cm2) × 0.1% = 25 W/cm2

Average optical power = 25 W/cm2 × 1.1944 cm2 = 29.86 W

Average absorbed optical power = 29.86 W × 0.33 = 9.85 W

= (1.8 W + 9.85 W) × 0.5 ºC/W = 5.8 ºC

Mirror Surface to Ceramic Delta: (ΔTMIRROR_SURFACE-TO-CERAMIC)

TMIRROR SURFACE - TCERAMIC = ΔTSILICON-TO-CERAMIC + ΔTBULK_MIRROR-TO-SILICON + ΔTMIRROR_SURFACE-TO-BULK_MIRRORTMIRROR_SURFACE - TCERAMIC = 5.8 ºC + 16.85 ºC + 0.85 ºC = 23.5 ºC

In the second example calculation, since tpulse and toff are both < , analysis is required over several pulses until the temperature rise stabilizes.

Example 2

A pulsed laser illuminates a DLP650LNIR DMD with 1064 nm wavelength light and fills the active array with no overfill.

Pulse duration (tpulse) = 10 ps

toff = 99.99999 (pulsed repetition rate of the optical source is 10 kHz)

Peak incident power during the pulse is 250 MW/cm2

Calculation of the temperature rise of the mirror surface above the DMD ceramic temperature:

- Mirror Surface to Bulk Mirror

Delta: ΔTMIRROR_SURFACE-TO-BULK_MIRROR

= temperature at time = t

= initial mirror temperature

q = absorbed heat flux on mirror surface [W/m2]

α = Mirror thermal diffusivity = 6.4667 x 10-5 m2/s

k = Mirror thermal conductivity = 160 W/m-ºC

q = 250 MW/cm2 × (1 – 0.94) = 15 MW/cm2

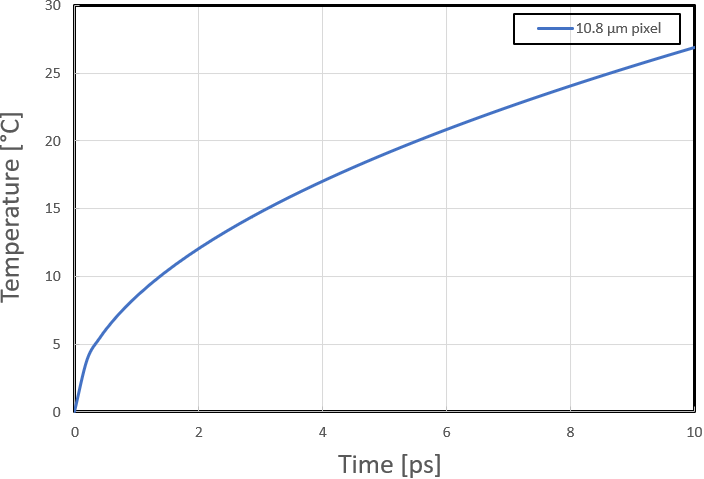

tpulse = 10 ps

T(10 ps) = 2 × 15 MW/cm2 × {[(6.4667e-5 m2/s × 1.0e-11 s)/π] /160 W/m-ºC} + 0 = 26.9 ºC

Figure 3-3 DMD Mirror Surface

Temperature Rise at 250 MW/cm2

Figure 3-3 DMD Mirror Surface

Temperature Rise at 250 MW/cm2 - Bulk

Mirror to Silicon Delta: ΔTBULK_MIRROR-TO-SILICON

= 250 MW/cm2 × (10.8 m)2 = 291.6 W= 0.931 (on-state)

at 1064 nm = 0.94

= 291.6 W × [0.931 × (1 – 0.94)] = 16.289 W

= 3.39 x 105 ºC/W

= 0 + 16.289 W × (3.39 x 105 ºC/W) = 5.522 x 106 ºC

= 32.27

toff = 99.99999

tpulse = 10 ps

= 5 × 32.27 = 161.35

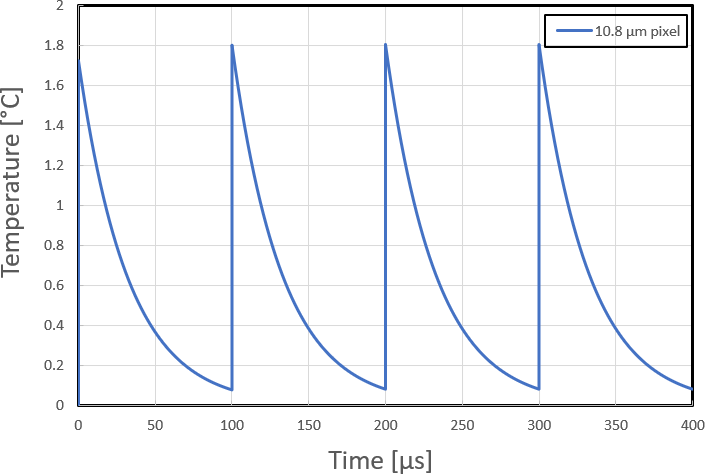

Bulk mirror only partially heats and partially cools between pulses and we need to iterate and analyze a series of pulses until the mirror temperature no longer changes.

1st tpulse heating:

T(10 ps) = 5.522 x 106 ºC + (0 – 5.522 x 106 ºC)e-(10 ps/32.27 μs) = 1.710 ºC

1st toff cooling:

T(99.99999 μs) = 0 ºC + (1.720 – 0 ºC)e-(99.99999 μs/32.27 μs) = 0.077 ºC

2nd tpulse heating:

T(10 ps) = 5.522 x 106 ºC + (0.077 ºC – 5.522 x 106 ºC)e-(10 ps/32.27 μs) = 1.787 ºC

2nd toff cooling:

T(99.99999 μs) = 0 ºC + (1.787 – 0 ºC)e-(99.99999 μs/32.27 μs) = 0.081 ºC

3rd tpulse heating:

T(10 ps) = 5.522 x 106 ºC + (0.081 ºC – 5.522 x 106 ºC)e-(10 ps/32.27 μs) = 1.791 ºC

3rd toff cooling:

T(99.99999 μs) = 0 ºC + (1.791 – 0 ºC)e-(99.99999 μs/32.27 μs) = 0.081 ºC

4th tpulse heating:

T(10 ps) = 5.522 x 106 ºC + (0.081 ºC – 5.522 x 106 ºC)e-(10 ps/32.27 μs) = 1.791 ºC

4th toff cooling:

T(99.99999 μs) = 0 ºC + (1.791 – 0 ºC)e-(99.99999 μs/32.27 μs) = 0.081 ºC

Notice the temperature did not change from the 3rd pulse to the 4th pulse. When the temperature after each pulse iteration stops changing, it has reached steady-state. The bulk mirror temperature rise above the silicon is 1.8 ºC.

Figure 3-4 DMD Bulk Mirror

Temperature Rise at 250 MW/cm2

Figure 3-4 DMD Bulk Mirror

Temperature Rise at 250 MW/cm2 - DMD silicon temperature rise

above ceramic: ΔTSILICON-TO-CERAMIC

From the DLP650LNIR data sheet:

= 0.5 ºC/W

= 1.8 W

= 0.726 (off-state)

at 1064 nm = 0.94

at 1064 nm = 0.007 (per pass)

= 0

= (1 - 0) × {[0.726 × (1-0.94)] + [1-0.726]} + (2 × 0.007) + 0

= 0.33 (off-state)

= total incident average optical power to DMD

Active array area = (1280 × 10.8 μm) × (800 × 10.8 μm) = 1.1944 cm2

tpulse = 10 ps, toff = 99.99999

Therefore pulse duty cycle = 10 ps / ( 10 ps + 99.99999 ) x 100% = 0.00001%

Average optical power density = (250 MW/cm2) × 0.00001% = 25 W/cm2

Average optical power = 25 W/cm2 × 1.1944 cm2 = 29.86 W

Average absorbed optical power = 29.86 W × 0.33 = 9.85 W

= (1.8 W + 9.85 W) × 0.5 ºC/W = 5.8 ºC

Mirror Surface to Ceramic Delta: (ΔTMIRROR_SURFACE-TO-CERAMIC)

TMIRROR SURFACE - TCERAMIC = ΔTSILICON-TO-CERAMIC + ΔTBULK_MIRROR-TO-SILICON + ΔTMIRROR_SURFACE-TO-BULK_MIRRORTMIRROR_SURFACE - TCERAMIC = 5.8 ºC + 1.8 ºC + 26.9 ºC = 34.5 ºCIn the second example, the mirror surface temperature rise above the bulk mirror is much larger than the bulk mirror temperature rise above the silicon. This is common with very short pulses of high intensity. Notice the average power is the same between examples 1 and 2 (29.86 W) and therefore the temperature rise of the silicon above the ceramic is equal in the two examples.