SBAA436 March 2021 REF34-Q1 , REF3425 , REF3425-EP , REF3430 , REF3430-EP , REF3433 , REF3433-EP , REF3440 , REF3440-EP , REF3450 , REF4132 , REF4132-Q1 , REF50 , REF5020-EP , REF5020A-Q1 , REF5025-EP , REF5025-HT , REF5025A-Q1 , REF5030A-Q1 , REF5040-EP , REF5040A-Q1 , REF5045A-Q1 , REF5050-EP , REF5050A-Q1 , REF50E , REF6125 , REF6133 , REF6141 , REF6145 , REF6150 , REF6225 , REF6230 , REF6233 , REF6241 , REF6245 , REF6250 , REF70

5 Test Setup

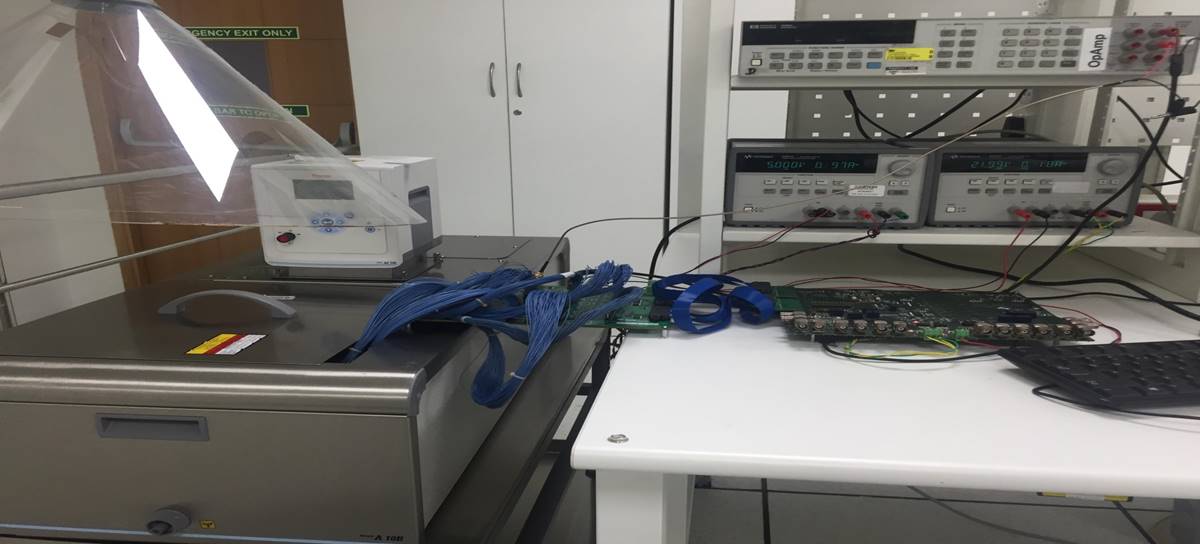

At TI, LTD test is done on fully automated multisite bench setups. An example of one setup is shown in Figure 5-1. The PCB assembly is done with solder reflow to mimic exact application board condition and get uniform solder stress profile across all the devices. The PCB board and devices are fresh and not pre-baked. Oil bath is used to provide very stable temperature (±0.01°C variation) environment. All the devices are always powered on. Output of all the references are measured by 8.5 digits DMM after every half an hour. DMM is calibrated before each measurement cycle. All the error sources on the bench setup are calibrated with respect to Fluke732B voltage standard. LTD oil bath is above the room temperature (35°C) to avoid variations in room temperature causing any issues.

Figure 5-1 LTD Oil Bath Setup

Figure 5-1 LTD Oil Bath Setup